Press release

FastPic5 Software Makes VLM’s Even Smarter

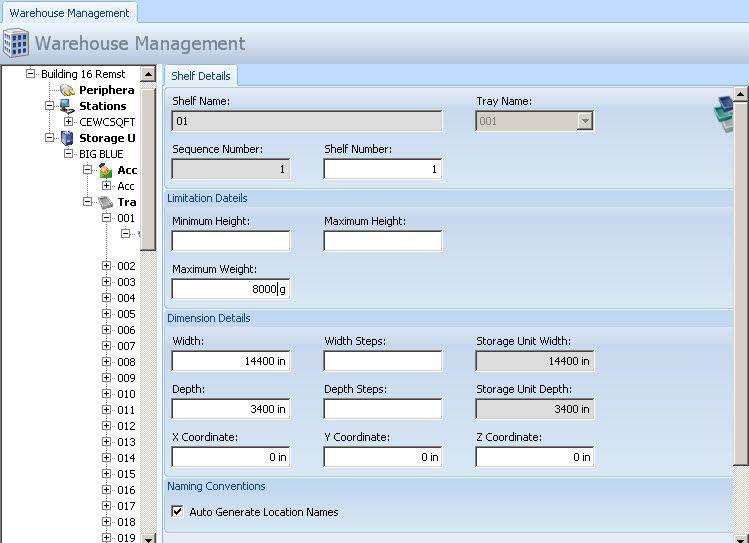

FastPic5 inventory management software saves time, increases efficiencies and maximizes storage density by managing height and weight restrictions. While the unit can control these features, FastPic5 inventory management software is designed to proactively supervise this function resulting in an even smarter Shuttle Vertical Lift Module (VLM).Using the height restriction feature in FastPic5, each tray can be preset with a maximum height for stored goods. To maximize storage density within a VLM most efficiently, each tray should contain parts of the same approximate height. Using FastPic5 prevents the operator from increasing the overall tray height, restricting the operator from creating wasted cube. For example, if a tray has been loaded with parts all 8” high, the tray could be set to store goods at a height of 8”, and 8” only. This will prevent the operator from loading that 8” specified tray with a 10” part, and creating 2” of wasted space.

The VLM manages this function by scanning the height of the tray as the extractor brings the tray back into the machine and stores it. To prevent losing space, if a restricted tray height is exceeded the VLM will deliver the tray back to the access opening and identify to the operator that the restricted height has been exceeded. Operators can set the height restriction of each tray individually.

Using the weight restriction feature, FastPic5 can also manage the weight held on each tray, as well as the total unit weight. Using FastPic5 each tray weight capacity is preset as light, medium or heavy. FastPic5 then directs the operator to put or store a part in an assigned location where there is adequate weight capacity, never exceeding the tray or unit weight. Managing tray capacity is important to keep functionality of the machine running at full speed. Using FastPic5 to manage storage locations and weight capacities ensures the VLM will be loaded efficiently, preventing wasted time from manually managing the weight capacity.

Space is always a factor when looking to improve any operation. While the height and weight of stored parts can be managed by the VLM, FastPic5 increases efficiencies making operations smarter. FastPic5 proactively manages the height and weight restrictions in a VLM- saving time and effort, while increasing efficiency and productivity.

Kardex Remstar, LLC, a company of the Kardex Group is a leading provider of automated storage and retrieval systems for manufacturing, distribution, warehousing, offices and institutions. For information about our dynamic storage solutions, call 800-639-5805, visit www.KardexRemstar.com.

Kardex Remstar

41 Eisenhower Drive

Westbrook, ME 04092

800-639-5805

Press Contact:

Christina Dube

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release FastPic5 Software Makes VLM’s Even Smarter here

News-ID: 222412 • Views: …

More Releases from Kardex Remstar

Shuttle XP 1000: easy handling of heavy loads

Neuburg/Kammel, 11.11.2013. There is a new addition to the successful Shuttle XP storage lift series from Kardex Remstar. Besides the 250, 500, and 700 models, the dynamic storage system now also includes the Shuttle XP 1000 model. Parts weighing up to 1,000 kg per tray can be stored using the new unit. The new solution from Kardex Remstar allows even companies with heavy goods to organize their work processes more…

Kardex Remstar To Display Expanded Product Line At Modex 2014

The Kardex Remstar product line continues to grow with industry demand. Kardex Remstar will display an expanded product line of Shuttle® XP Vertical Lift Modules (VLM) and Megamat RS Vertical Carousels at Modex 2014 in Atlanta, GA March 17-20 in booth #9323. The extended product line fit into a variety of new applications, improving efficiencies and increasing profits.

Now, the Shuttle XP VLM ranges from light duty storage in the…

Kardex Remstar To Feature New Software Kiosk Function At NADA 2014

A Shuttle® XP Vertical Lift Module (VLM) featuring a new kiosk picking function will be on display in Kardex Remstar booth #2601 at NADA 2014 in New Orleans, LA January 24-27. The new kiosk function available with Power Pick Global software simplifies the picking process to keep automotive dealership parts departments at maximum performance - improving productivity, saving floor space and increasing accuracy.

Using the kiosk function, items are inventoried…

More Releases for FastPic5

13 Ways To Do MORE With Less in 2013

With slow growth predicted for many industries in 2013, organizations are taking a minute to review their current material handling strategies and operations, asking themselves “how do we do more with less?”. A little more of “this” and a little less of “that” can be the perfect recipe to maximize material handling efficiencies; leading to reduced operational costs and higher productivity rates. Here are 13 tips to help…

Automate Accuracy with FastPic5 Cycle Counting

Keeping inventory accurate is always a challenge, especially in a fast paced work environment. No matter how your materials are stored, cycle counting is necessary to ensure accurate inventory. FastPic5 Inventory Management Software from Kardex Remstar offers a cycle counting feature to quickly and easily verify the physical inventory. Regular cycle counting minimizes inventory discrepancies and prevents inventory shortages.

FastPic5 inventory management software has a built in cycle counting feature allowing…

Zone Handling Provides Inventory Control, Improved Productivity and Ergonomics

The zone handling feature of FastPic5 inventory management and control software from FastPic Systems offers inventory control, improved productivity and ergonomics. The zone handling feature allows users to define zones within a warehouse or storage unit and then assign specific inventory to the defined zones.

Zone handling is different than dedicated storage. With dedicated storage a specific part is assigned to a specific location. While this maximizes control, it decreases storage…

Goods to Person Principle Increases Productivity and Ergonomics

Changing the order picking process to utilize a goods to person principle can increase productivity by 2/3 and improve worker ergonomics. Dynamic storage systems from Kardex Remstar brings the work to the worker; eliminating the time spent to walk to the specific location to retrieve the item.

Using a standard shelving system workers walk up and down the aisles searching for the items they need, very similar to grocery…

Kardex Remstar Vertical Storage and Retrieval Systems Help Medical Device Compan …

The Food and Drug Administration’s concern for the safety and effectiveness of Class II and III medical devices is described in 21 CFR Part 820, which details quality system regulation for medical device manufacturers.

Record keeping requirements and mandated quality control processes are described in Subpart L, Handling, Storage, Distribution and Installation. These sections direct medical device manufacturers to establish and maintain procedures to ensure that mixups, damage, deterioration, contamination…

Utilizing Kardex Remstar Automated Storage and Retrieval Systems in Maintenance …

Gone are the days with one eight hour manufacturing shift, many automated facilities today run production machines through the night with very few machine operators, making machine maintenance and repair a valuable operation. Kardex Remstar automated storage and retrieval systems increase production machine uptime by improving technician efficiency, increasing accountability and eliminating part shortages in maintenance operations.

Having maintenance and repair parts in stock and readily accessible at…