Press release

Innovative Routing Technologies- Depth Routing

Mechanical routing technology is ideal for PCB manufacturers who target high tech markets and prepare themselves for the customer’s demands of today and tomorrow. Depth routing technology supports a high end market with the need for accuracy, miniaturization, process stability and the need for productivity.The market's demands for finer structures have grown considerably over the years. Aside from smaller components, PCB dimensions for rigid and flex circuits have become increasingly smaller and lighter. Therefore, the products have been made smaller and faster. In effect, one technology has been a driver for the other. As miniaturization trends continue this course will make technological improvement and design creativity in the PCB production process indispensable.

Increases in component packaging density and the demand for more functionality have continued to drive design rules toward achieving a higher and higher interconnection density. With new designed circuit boards, one must deal with increased complexity and smaller tolerances. Therefore the need for accuracy has reached a new level and designers and manufacturers are faced with smaller tracks and vias.

In the context of drilling and routing, laser technology has enjoyed a fair share of publicity. For a long time, some considered laser technology to be the replacement for traditional mechanical processing. Lasers might play a leading role in current and future market demands, but there still are a lot of questions to be answered and a long way to go in terms of productivity and flexible capabilities.

The new market specifications for precision and tolerance can be supported by mechanical processes. Therefore interest in mechanical drilling and routing processes is still on the radar. During the last years, improvements in drilling machine capabilities have been achieved. Drilling productivity is no longer an issue today with the current generation of drilling machines and new technologies in place like dual spindle technology, (see my article on Dual Spindle Technology). Linear motors allow substantially improved path accuracy in routing and routing of complex forms. Precise definition of micro-vias, hole geometry, excellent hole-wall condition and accurate depth control allow for further options beside ‘standard’ drilling.

Mechanical circuit board processes however have some advantages like easy adjustments or lower costs. Over the years mechanical drilling and routing had been developed quite significantly. There is a new generation of demand in the market for system capabilities, tolerances and applications. The market shows a trend to flex and flex-rigid boards. Certain microwave designs where relatively large surface areas have to be crossed is a special challenge for routing and controlled-depth milling. All of this displays a clear trend towards multiplicity and flexibility which needs to be offered by equipment manufacturers.

The Swiss Posalux machine analyzed below, allows depth routing with an accuracy of +/- 15.0 um. Up to now, this seemed impossible with the focus being only on laser technology. However the strength of a drilling machine is still accuracy based performance. The depth routing option allows for very complex designs, bended boards and structures to be processed with fine precision.

A customer evaluation project for the advanced depth routing use of a routing system had been performed. I will share some valuable results and capabilities with you.

Depth routing technology- applications

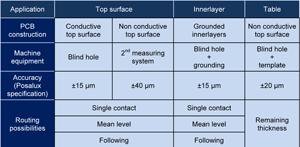

To offer a structure, I will differentiate three areas of applications for the use of depth routing.

Option 1 is routing the top of the surface

Pocket routing for components is used on rigid-flexible Printed Circuit Boards. The top surface will be milled away (taking the height of the chip and board into account). Considering a larger area must be traversed, the detection of the real surface structure is a key element. With non conductive top surfaces a 2nd measuring system is needed. Different detection and calculation methods, (see below), can be used. An accuracy of +-40 um is achievable with non conductive surfaces and +- 15 um on conductive spots. Pocket routing is mainly used if you need smaller boards and a lower board thickness for buried processors or resistors.

Option 2 is routing down to the innerlayers

In some applications a board needs to be designed with grounded innerlayers and free contact surfaces on an innerlayer, which are required to be connected to a chip. Designs should avoid tracks around the hole and above the chip. A nearby contact could falsely report the system as a closed loop and cause a false measurement, guiding the spindle to an undesired position. Customers currently use up to 12 layers in standard practice and production. The main reason for OEMs to use this kind of design is space, speed (shorter tracks) and EMC requirements. Technology-wise there are no limitations in layer count. As more layers are added, it becomes more difficult for the system to detect the right target layer and to measure the depth.

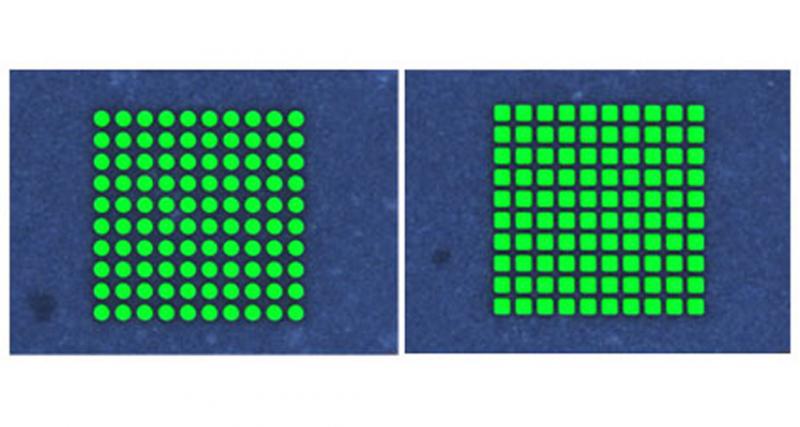

This type of depth routing technology allows designers to sink in a chip below the board surface and design a second chip above it. Routing leaves a square donut in between the connections of the two chips. Accuracy is within +/-15 um.

This advanced design causes less EMC problems due to the symmetry and the short distance between the components instead of using long tracks to connect them. But the real challenge is to evacuate the heat from in between the two components. This issue can be addressed by implementing an air channel and the integration of heat pipes.

Option 3 is routing semi flexible FR4 and rigid-flexible PCBs

Depth routing for semi flexible FR4 and rigid-flexible boards will be used if your board designer requests a bended board (which can be folded once). A part of the board will be milled away with an accuracy of +-20 um. As a result, the board can be bended, less space is needed and the product therefore can be smaller in size. Because there is no conductive area in which to measure, the table of the drilling/ routing machine will be used to detect the depth (detection methods see below).

Detection methods to control depth

In all of these applications the special challenge has to do with depth controlled drilling and milling. CO2 laser systems naturally stop cutting when contact has been made with the copper on the innerlayer. Mechanical systems require very precise measurements and feedback to achieve exact depth control. With the different available applications and products available, various measurement types are possible and necessary.

‘Contact drill’ and routing with single contact measurement

With 'contact drill' each hole is individually measured. Through this method, the desired result (through mechanical micro-via drilling) can be achieved. The drilling tool is electrically connected and makes contact with the copper foil surface. A known zero reference determines the hole depth. Base material warp is compensated and the consistent hole depths are ensured.

This becomes more difficult when we talk about routing. With a single contact measurement, surface determination will be done at the tool entry location. The only reference point is the entry point and therefore the depth remains constant during the entire routing process. The milled depth depends directly on the uniformity of material thickness. For relatively small boards and well defined top surfaces, traditional ‘one point/ single contact’ depth measurements may suffice. Though, it is seldom that single contact routing is used in the industry.

With thinner laminate layers and when areas get larger, it becomes more important to take the real differences of the substrate surface and thickness into account. Continuous monitoring and measurement or mean calculation become necessary.

‘Contact drill’ and routing with mean level measurement

With mean level measurement the surface level is measured at several locations. Several points with an electrical loop will be used. With the measured points and the received data, a mean contact level is calculated by interpolation. The routed depth is kept constant by the 2nd measuring system (also called floating). The system allows for a depth-control accuracy of +/- 15 microns throughout the operation.

Routing with second measuring systems

Surface detection with a second measuring system does not need a conductive surface. Routing is accurately controlled by a Z axis servo. There are two measuring systems per spindle. The first determines the exact height of the tool at the point of entry. The reading head is fixed on the drilling head. The second measuring system is linked to the Z axis controller and controls the Z-axis cutting depth and continuously compensates for surface topography. The linear scale is mounted on the pressure foot.

As soon as the pressure pad touches, the reading head starts to count. At first the difference between the tool and the pressure foot is measured. Then the routing process begins (with the calculated depth). This measurement method is less accurate (+- 40 um) than using a contact loop. Therefore a workaround for BGAs is sometimes used. A single sided copper foil on the backside of the chip can be integrated and a measurement can be done from there.

The pressure foot is also necessary because of the real board topography. The pressure foot will be used to achieve better results for applications with the flatness deviation of > 0,4-0,5 mm. The foot eliminates board lifting by providing downward pressure. This allows you to mill, rout and drill without boards lifting from the table during the entire process.

Additionally, a single-spindle machine can feature optical registration and monitoring with a CCD camera. The routing picture will be aligned to the printed image. The camera recognizes the fiducials and will correct measurement calculations and apply them to the routing system.

Second measuring system routing with “following method”

The most advanced method to measure depth is the “following method“. The spindle runs 2 times. First it runs to find the conductive surfaces and then to rout. The copper’s thickness needs to be at least 15 um minimum. The major disadvantage of the “following method” is speed. The method is approximately 200-250% slower than the mean method.

Bottom of panel referenced routing

With non conductive top surfaces, the bottom of a PCB will be used as a reference to calculate the depth. This routing type is mainly used for rigid-flex FR4 boards. The automotive industry with applications like dashboards or ABS systems and the telecommunication industry with mobile phones drive this technology in the main. The contact drill method is used to map an aluminium template. This mapped template data is used during the routing to correct the routing depth. This type of method is also used to separate the rigid-flexboard.

Herbert Kläy, Director of the PCB division of the Swiss Equipment manufacturer Posalux, shared his views about the process and the future of the technology. “Today’s customer’s needs, for productivity and accuracy, (with the miniaturization and the new set of products) can be handled with the above mentioned methods and technologies. Even aluminium backed up PCBs for LEDs and the automotive industry can be processed. In our developmental strategy it is expected that more R+D developments and improvements will be made over the next coming years.”

The development of CO2 lasers should also be watched closely, but as of today, lasers are no real alternative for depth routing. If one has to deal with large areas and larger material volumes on boards, productivity is the main challenge and R+D departments have only started to experiment with the technology for depth routing. When it comes to larger boards heating up, limited flexibility and scanning processes become additional problems. Therefore the laser technology has not been fully spread out in the market yet, although short-term laser depth routing may be an alternative for small boards or build-up technologies on substrates. In a couple of year’s time it will be apparent if the laser technology path will be cost-effective. Laser machines can be up to 1-2 time or more than the price than single drilling machines. The productivity benefit may also be visible if you have many blind holes on your products. Due to budget reasons, most laser drill systems using a single laser source limit speed and productivity. Many laser systems are using > 4 J/cm2 for opening the Cu surface. With organic materials like polyimide or exposy resins, only 100 mJ/ cm2 is needed. This is a wide spectrum and the laser system demands a very advanced energy control to handle the various types of drilling steps.

The System’s flexibility is also limited due to the fact that you must first decide which wavelength is best, considering you have the ablation performance, materials and absorption ratio in mind. The laser spot size (which is 70 um with CO2 lasers) is an additional challenge in drilling microvias. Another constraint is the mechanical board design which might not deliver the same quality and repeatability in the micrometer range. Therefore there is still sufficient scope for the use of mechanical drilling and routing.

The Swiss drilling and routing machine can be configured with asynchronous drilling and routing spindles, which have a rotation speed range from 15‘000 – 125’000 rpm and a tool diameter range of 0.1 – 6.35 mm. If larger diameters and standard PCBs are used, synchronous routing spindles with a high torque at low speed and a speed range of 5‘000 – 60‘000 rpm can be used. In this case maintenance is lower and spare parts are relatively easy to find.

In Conclusion

Mechanical routing technology is ideal for PCB manufacturers who target high tech markets and prepare themselves for the customer’s demands of today and tomorrow. Depth routing technology supports a high end market with the need for accuracy, miniaturization, process stability and the need for productivity.

Key markets for routing technology include: telecommunications, automotive as well as niche markets such as aerospace.

A significant advantage of the mechanical routing process is flexibility. Mechanical routing processes can offer a wide range of applications and the use of organic and non-organic materials like polyimide or exposy resins, copper – brass PCB with ceramic insulation layer and alloy (aerospace products). Routing with oil mist for non-ferrous materials is also available.

Automatic tool changes and spindle direction turns (reversed rotation) offer accuracy and productivity. Due to this fact, burr issues will be reduced by routing from both sides. The different applications and detection methods to control depth offer a wide range of products which can be utilised.

The Swiss Equipment manufacturer developed a sophisticated interpolation algorithm which improves the accuracy and productivity while routing complex contours. This method also considerably reduces the tool wear and increases the lifetime of the routing tool.

To use the described design options, some depth routing manufacturing know-how and the right equipment is necessary. Therefore a close relationship between designers and PCB manufacturers has proven to be helpful.

Moreover, in various markets there is a rising demand for this kind of high-end technology. And as of today, some PCB shops and markets might stand a better chance to differentiate themselves from their competitors.

---- Foot notes ----

The Swiss manufacturer is Posalux. Posalux is a leading Swiss equipment manufacturer. The company builds high-tech drilling and routing machines for the PCB industry and special EDM and laser drilling machines for the machining of holes into nozzles for direct fuel or diesel injection for the automotive industry.

Volker Feyerabend is President of APROS Int. Consulting and Services (www.APROS-Consulting.com). He has a degree in Engineering and Economics. He has worked for Hewlett Packard, Agilent Technologies, Groz-Beckert in various international senior management positions. He also headed a European Outsourcing Organization with the focus on EMS/ PCB companies. Contact him

APROS Consulting:

Strategy and Management, Int. Consulting, Process- and Costs, IT and Marketing and Sales

APROS Services:

PR, Communication and Advertisement , Sales Support IT-Administration and Coaching

APROS Int. Consulting & Services

Volker Feyerabend

Rennengaessle 9, 72800 Eningen, Germany

Reutlingen, Tuebingen, Stuttgart, Atlanta, Capetown

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Innovative Routing Technologies- Depth Routing here

News-ID: 211842 • Views: …

More Releases from APROS

Posalux: Lasers for all Environments

Laser light can become a powerful tool when integrated into a high-precision machinetool environment. Posalux offers such machine-tool solutions for the micromachining of various applications in the medical, electronic and automotive industry.

Since the company introduced the first FEMTO laser machine for the automotive industry, it has added more applications to its portfolio. With the recent development of the model FEMTO MONO, Posalux offers a compact yet versatile solution for…

Femtolaser - Micro-drilling and processing with unprecedented precision

The new individual Posalux series has been successfully tested on the market - Femtolaser

Swiss Posalux has been on the market since 1943. Its laser drilling machine has now been expanded to include microtechnology. Drilling at unprecedented precision and speed have become possible.

One femtosecond (1 fs) corresponds to 10-15 seconds, a quadrillionth of a second. A femtosecond, 0.000,000,000,000,001 seconds, is an unimaginably short unit of time for the impulse frequency…

6-digit investments in state-of-the-art technology in PCB production

Product developers know that they need to engage in a close exchange with the producers at all times for prototypes of their PCBs to ensure that they are producible as planned. Exotic or highly innovative requirements quickly reach the limits of feasibility, since the production lines are not designed for certain prototypes or demands. Becker & Müller Schaltungsdruck GmbH from Kinzigtal in the Black Forest know this, of course. Prototype…

More Releases for PCB

Victory PCB Showcases High-Quality Double-Sided PCB Solutions for Modern Electro …

Victory PCB highlights the performance, flexibility, and cost-effectiveness of its double-sided printed circuit boards, designed to meet the demands of mid-complexity electronic systems.

Victory PCB, a professional printed circuit board manufacturer, continues to support modern electronics development through its high-quality double-sided PCB manufacturing solutions [https://www.victorypcb.com/products-category/double-sided-pcbs.html]. Designed to balance performance, reliability, and cost efficiency, Victory PCB's double-sided printed circuit boards are widely used across industries that require greater circuit density without the…

Victory PCB Expands Global Reach with Industry-Leading PCB Manufacturing & Assem …

Image: https://www.abnewswire.com/upload/2025/06/aa56d146ab76e34a4f335137dad3dd49.jpg

Victory PCB [https://www.victorypcb.com/], a global leader in printed circuit board (PCB) manufacturing and assembly, continues to set new benchmarks in high-quality PCB production, fast delivery, and customer service excellence. With a legacy of 19 years of innovation and precision manufacturing, Victory PCB is powering the next generation of industries, from automotive and medical equipment to aerospace and advanced communication devices.

Located in the heart of Shenzhen's modern Industrial Park, Victory…

Victory PCB: Pioneering Excellence in Global PCB Manufacturing and Assembly

Image: https://www.abnewswire.com/upload/2025/01/fabf105f8930f331e50cb1ca439637fe.jpg

Victory PCB [https://www.victorypcb.com/] is a renowned global manufacturer of PCBs and assembly services, recognized worldwide for its exceptional precision, innovation, and commitment to quality. With a client base exceeding thousands across various sectors, including automotive, aerospace, medical, industrial automation, and communication technologies, PCB solutions are tailored to meet each client's needs.

With centers covering as much as 30,000 square meters, Victory PCB employs over 450 staff dedicated to producing high-quality…

Victory PCB: Redefining Global Excellence in PCB Manufacturing and Assembly

Image: https://www.abnewswire.com/upload/2025/01/986e29984b844645f2a99a0a5e93a4c8.jpg

Having almost 20 years of expertise in producing and assembling printed circuit boards (PCBs), Victory PCB has established a solid reputation for providing high quality products, creative solutions, and consistent customer satisfaction. Victory PCB [https://www.victorypcb.com/], located in a contemporary 30,000-square-meter facility within Shenzhen's tech district, merges deep expertise with cutting-edge technology to manufacture products that bolster top industries worldwide. Relying on more than 1,000 clients and 80% of its…

Victory PCB Emerges as a Global Leader in PCB Manufacturing

Victory PCB has been delivering custom PCB solutions to global customers since 2005.

Image: https://www.abnewswire.com/uploads/3daf3e2d61300e7406f7fb61c56726fc.png

Victory PCB [https://www.victorypcb.com/], a professional printed circuit board (PCB) manufacturer established in 2005, is setting new standards in the global electronics industry with its commitment to top-quality, high-precision, and high-density PCB solutions. The solutions offered by Victory PCB, which exports 80% of its products worldwide, bridge the gap between concept and reality for clients in a variety…

PCB Ceramic Substrate Market Size, Share and Forecast By Key Players-Panda PCB T …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- According to the MRI Team's Market Research Intellect, the global PCB Ceramic Substrate market is anticipated to grow at a compound annual growth rate (CAGR) of 13.62% between 2024 and 2031. The market is expected to grow to USD 21.58 Billion by 2024. The valuation is expected to reach USD 52.73 Billion by 2031.

The PCB ceramic substrate market is experiencing robust growth, fueled by the rising demand…