Press release

Femtolaser - Micro-drilling and processing with unprecedented precision

The new individual Posalux series has been successfully tested on the market - FemtolaserSwiss Posalux has been on the market since 1943. Its laser drilling machine has now been expanded to include microtechnology. Drilling at unprecedented precision and speed have become possible.

One femtosecond (1 fs) corresponds to 10-15 seconds, a quadrillionth of a second. A femtosecond, 0.000,000,000,000,001 seconds, is an unimaginably short unit of time for the impulse frequency of laser light emission. The light beam moves approx. 0.3 µm away from the light source during this brief period. This is about a hundredth of a human hair. In a nutshell: a femtosecond laser permits extremely precise work.

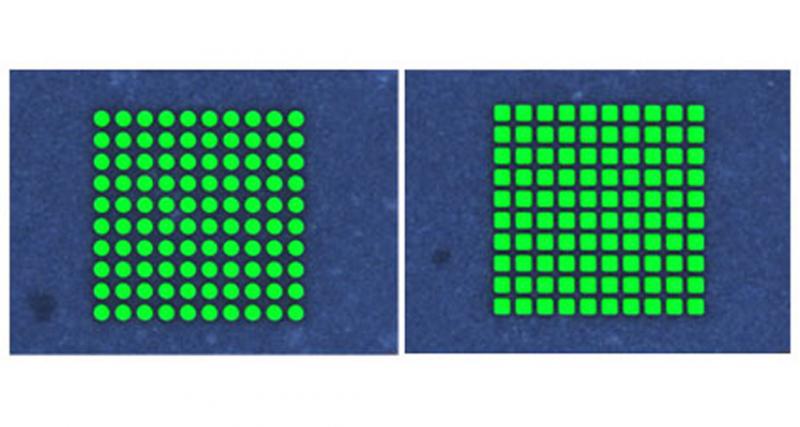

Such lasers are mainly used in ophthalmic surgery. Thanks to the combination of a USP (ultrashort pulse) laser and a 5-axis scanner, Posalux now also offers a machine that can produce the smallest hole geometries, e.g. for micro-electronics. Hole geometries are not limited to conventional shapes such as cylinders. Rectangular, conical (positive and negative) or entirely different shapes can be produced as well. Even materials that are usually difficult to machine can be easily handled well with the help of femtolaser technology.

Posalux has introduced a new product to meet the complex market requirements of applications in test electronics: the "probe cards". The necessary market analyses and development of the first femtolaser customer system took about 18 months. The new Posalux technology already sees increasing use on the Asian market.

In 2017, customers provide quite curious about the technology when it was presented and discussed at trade fairs and conferences in the USA and Asia. The first step fit market needs precisely. The order books filled up well. Several machines are already in production at customer sites, meeting the high demands of mass production. The new system technology has proven its worth in practice perfectly.

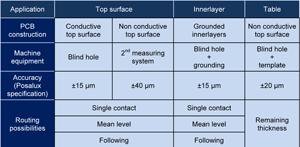

The new Posalux machine series can drill micro holes of less than 30 µm for production of high-precision test systems in various industries! Probe cards and test adapters for electronic components, such as BGAs, memory components, complex chip systems or packed complete systems can be produced with optimal support.

Test needles are guided through a plate substrate in the test heads. They are used to measure the precision contacting. Mechanical drills are not the best solution for their manufacturer, due to increased wear. Mechanical drilling does not permit hole geometries that deviate from the standard geometry in this machining process. The advantage of laser drilling is obvious. Mechanical drills that drill into hard ceramics quickly dull and need to be replaced. Laser drilling uses the power of light, dispensing with a drilling insert that would wear mechanically. Laser pulses are also much easier to control. The intended precision is a lot higher. Complex hole geometries can be implemented with perfect precision and repeated just as accurately.

The extremely short pulse times of the femtolaser prevent thermal effects on the material and reduce quality issues. There is no thermal interaction between the electrons and the particle grid below 500 femtoseconds. The new system has process times that are many times shorter than those of conventional systems. Once, these steps would take weeks. Today, they are finished in mere hours or days, depending on application.

The Posalux system uses a precession head for highly precise control of the laser beam. This enables highly accurate and repeatable results. With a precession head, the beam guidance and drilling strategy are chosen to avoid any damage to the hole edge. In combination with the femtolaser, this leaves zones unaffected by material removal or destruction. The femtolaser used works with pulse lengths below 300 femtoseconds for excellent results.

A high-precision XY table with a total area of 300x300 mm is of great advantage for the accuracy of the femtolaser system. It permits economical machining of several parts on one substrate without re-clamping. Software specially developed by Posalux permits optimal implementation of customer-specific drawing files for processing in the machine. This increases customer productivity and reduces potential error sources. Posalux already supplies solutions for tomorrow's needs. Its customers are investing in the future.

Once programmed for a plant, any manufacturing process can be repeated at any time. This eliminates the costs for new system settings. The time needed for setup becomes less relevant across the entire product life cycle.

The Swiss company has been active on the market for 75 years. It originally hails from the watch industry. Posalux has become established in the printed circuit board industry with highly productive mechanical drilling machines. Later, they offered drilling and eroding machines for the automotive industry in the field of micro-drilling for injection nozzles. The Swiss company also offer SACE, a technology for glass processing in the micro range. In the last few years, the portfolio has been expanded to encompass laser drilling machines with a view to innovation and customer focus. The original target group was the automotive industry. Posalux now also offers femtolaser drilling machines for the electronics industry, not least thanks to the achieved high application know-how. This market segment poses enormous demands. Services, innovations and technologies that add value for the customer are vital today. The company has 100 employees at its headquarters in Biel/Switzerland and its subsidiaries in Taiwan, Korea, Italy, along with a new branch office for sales and service in North America. They follow this goal and supply customers worldwide.

Posalux has invested a lot into its development centre, its employees and the corresponding measurement technology. The company's motto and customer-focused philosophy calls for competent support on site ensure that only impeccable machines are delivered. Trusting partnerships are necessary for joint development projects and customer-specific solutions.

The niche segment for testing equipment on the semiconductor market has been developed. Future-oriented technology and new positioning strive for a leading position in the industry. "The electronics market itself will continue to grow. Increasing use of electronics throughout all areas of life and the development of new technologies, for example in road traffic leads to a demand for more test equipment. The equipment industry will profit from this general trend." Sales manager Christof Kock is certain that the company is on the right track.

More information: https://www.posalux.com

APROS Consulting & Services GmbH

Volker Feyerabend

Germany, Rennengaessle 9, D- 72800 Eningen

Tel. +49 (0)7121-98 0 99-11

Wir sind Spezialisten mit Erfahrung aus Management und Fachbereichen mit ergänzendem Know-How.

Als Dienstleister können wir Ihre Arbeit durch unsere Services unterstützen.

Know-how und Do-how Idee und Umsetzung

Sie bekommen nicht nur Konzepte. Wir erarbeiten schnell und unbürokratisch gemeinsame, individualisierte Lösungen. Diese planen wir praxisnah, setzen diese um und überprüfen.

Wir verstehen bestehende Grenzen und überwinden diese innovativ aber verträglich.

Um der zunehmenden Internationalisierung Rechnung zu tragen, arbeiten wir weltweit und sind an verschiedenen Standorten.

Wir folgen konsequent der Philosophie - Umsetzbarkeit ist der Schlüssel der Beratung - und lassen uns daran messen.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Femtolaser - Micro-drilling and processing with unprecedented precision here

News-ID: 2076473 • Views: …

More Releases from APROS

Posalux: Lasers for all Environments

Laser light can become a powerful tool when integrated into a high-precision machinetool environment. Posalux offers such machine-tool solutions for the micromachining of various applications in the medical, electronic and automotive industry.

Since the company introduced the first FEMTO laser machine for the automotive industry, it has added more applications to its portfolio. With the recent development of the model FEMTO MONO, Posalux offers a compact yet versatile solution for…

6-digit investments in state-of-the-art technology in PCB production

Product developers know that they need to engage in a close exchange with the producers at all times for prototypes of their PCBs to ensure that they are producible as planned. Exotic or highly innovative requirements quickly reach the limits of feasibility, since the production lines are not designed for certain prototypes or demands. Becker & Müller Schaltungsdruck GmbH from Kinzigtal in the Black Forest know this, of course. Prototype…

Innovative Routing Technologies- Depth Routing

Mechanical routing technology is ideal for PCB manufacturers who target high tech markets and prepare themselves for the customer’s demands of today and tomorrow. Depth routing technology supports a high end market with the need for accuracy, miniaturization, process stability and the need for productivity.

The market's demands for finer structures have grown considerably over the years. Aside from smaller components, PCB dimensions for rigid and flex circuits have become increasingly…

More Releases for Posalux

CNC PCB Drilling Machine Market Size, Share, Growth, Analysis, Key Players, Reve …

CNC PCB Drilling Machine Market Size

The global CNC PCB Drilling Machine market was valued at US$ 605 million in 2023 and is anticipated to reach US$ 904 million by 2030, witnessing a CAGR of 5.9% during the forecast period 2024-2030.

View sample report

https://reports.valuates.com/request/sample/QYRE-Auto-39D16771/Global_CNC_PCB_Drilling_Machine_Market_Research_Report_2024

Market Trends for CNC PCB Drilling Machines:

1. Growing Demand for High-Precision PCBs

o The shift towards smaller, denser, and multi-layer PCBs in consumer electronics, medical devices, and telecom is driving the demand…

Current and Future Analysis of Femtosecond Laser Processing Market With New Busi …

A recent intelligence report released by Worldwide Market Reports with titled "Femtosecond Laser Processing Market Insights 2031". A detailed study accumulated to offer the latest insights about acute features of the Femtosecond Laser Processing market. This report highlights factors such as past and current trends, growth drivers, restraints, opportunities, risk analysis, regulatory scenarios, and technology development. This research report's main goal is to help key players understand the current state…

4-Axis Machining Center market: Players tapping Emerging Markets | Mikron Machin …

"The global 4-Axis Machining Center Market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global 4-Axis Machining Center Market. For instance, the market dynamics section digs deep into the drivers, restraints, trends, and opportunities of…

Ultrafast Laser Drilling Machine Market 2022| Global Leading Players, Industry U …

Market Summary

A newly published report titled "Ultrafast Laser Drilling Machine Market" by QY Research throws light on the industry dynamics and current and future trends that play a key role in determining the business expansion. The report also highlights the key driving factors and restraints that are impacting the growth. For a comprehensive understanding, the professionals have reviewed the regulatory scenario, market entry strategies, best industry practices, pricing strategy, technology…

Micromachining Market Size & Analysis - Forecast to 2026

The findings reviewed by GME stated that the Global Micromachining Market will expand with a high CAGR value from 2021 to 2026. The emerging demand for miniaturization of electric products, as well as the increasing preference for laser-based micromachining over the traditional approach, are driving the micromachining market's rapid growth.

Browse 159 Market Data Tables and 119 Figures spread through 189 Pages and in-depth TOC on "Micromachining Market - Forecast to…

Posalux: Lasers for all Environments

Laser light can become a powerful tool when integrated into a high-precision machinetool environment. Posalux offers such machine-tool solutions for the micromachining of various applications in the medical, electronic and automotive industry.

Since the company introduced the first FEMTO laser machine for the automotive industry, it has added more applications to its portfolio. With the recent development of the model FEMTO MONO, Posalux offers a compact yet versatile solution for…