Press release

The influence of sputtering targets on the manufacturing costs and efficiency of CIGS

The sputtering process is the most important technique for material deposition in CIGS-manufacturing. With innovative sputtering targets CIGS producers can significantly reduce their production costs.Manufacturers of sputtering targets like PLANSEE have two approaches to reduce CIGS module manufacturing costs: In order to lower the material consumption by a better target utilization PLANSEE introduced the new monolithic and dogbone rotary target designs. With MoNa the company offers a new material alloy that increases conversion efficiencies.

Changing the sputtering system from planar to rotary targets increases the target utilization from about 30 to 75%, which saves expensive raw material. Depositing the molybdenum back contact by monolithic molybdenum rotary targets - which are completely made of molybdenum - gives additional benefits: The expensive bonding of the molybdenum material on a stainless steel backing tube is not required. In addition, a higher sputtering power of up to 30 kW/m can be applied. This creates a very high heat load which cannot be accommodated by bonded-type targets: Indium is used as bonding material which melts at only 156 °C thus the risk of de-bonding is eliminated with monolithic targets. A higher sputtering power results in a higher deposition rate and improved thin film properties, e.g. higher electrical conductivity.

In contrast to the high lateral homogeneity of thin films deposited by sputtering, a sputtered target has generally an erosion profile which is not homogeneous – a result of different plasma densities. As a consequence, the targets have to be replaced even if there is sufficient material on most of the target area. To overcome this limitation, targets with varying outer diameter (named “dogbone” for rotary targets) or thickness is a solution to extend the target lifetime and increase the target exchange interval.

Two elements have a big impact on the CIGS cell efficiency: iron (Fe) and sodium (Na). Whereas iron degrades the cell performance by introducing defects in the CIGS structure, sodium has the opposite effect: It concentrates defects at grain boundaries, which is a requirement for achieving high efficiencies.

Low iron levels are only achieved by a high purity of the primary materials as well as a high quality manufacturing process. Especially for molybdenum targets the iron content can vary significantly. The traditional way to introduce sodium into the CIGS absorber is by means of a soda-lime-glass substrate. During the manufacturing process sodium diffuses from the glass through the molybdenum back contact into the absorber layer, resulting in a sodium concentration in the order of 0.1 at%. However, reproducibility and lateral homogeneity of this process is low, and flexible substrates do not act as sodium source.

Solar cell producers now have an easy alternative at hand: By sputtering a layer of sodium doped molybdenum, the amount of sodium in the absorber layer can precisely be controlled and reproduced. PLANSEE offers MoNa sputtering targets with high purity and a uniform and fine grained microstructure. Tests in cooperation with the Swiss EMPA institute have already proven their benefits in practice: With sodium doped molybdenum layers the efficiency of CIGS solar cells could be significantly improved.

PLANSEE is a world-leading manufacturer of products made from refractory metals and metallic composite materials. The privately owned company has been manufacturing innovative powder-metallurgically processed high-performance materials for over 90 years, and covers the whole production process, right from the raw material to the finished product. The company employs materials experts, product developers and local technical sales staff to provide customers all over the world with all the help and assistance they require.

PLANSEE SE

Nadine Kerber

Metallwerk-Plansee-Str. 71

6600 Reutte

Austria

nadine.kerber@plansee.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The influence of sputtering targets on the manufacturing costs and efficiency of CIGS here

News-ID: 208531 • Views: …

More Releases from PLANSEE SE

More efficient manufacturing of ceramic coatings: no problem thanks to PLANSEE's …

Hard and extremely durable: ceramic coatings make an ideal protective layer for tools and components. To date, ceramic and brittle materials could only be deposited by means of the reactive magnetron sputtering method, in part because of the lack of an appropriate fixing system for arc evaporation. But now PLANSEE has developed a suitable fixing system for ceramic and brittle composite materials. Using an integrated carrier plate and a cathode…

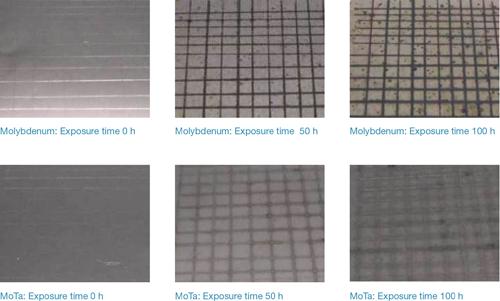

Molybdenum-tantalum: The corrosion-resistant material for CIGS solar cells.

Thanks to its good adhesion to glass and a high electrical conductivity, molybdenum is the back contact material in CIGS solar cells. However, exposed to corrosive atmospheres molybdenum can be prone to oxidation. In order to avoid negative effects during the manufacturing process and the solar module operation, PLANSEE has developed a material with improved corrosion resistance.

The company alloys pure molybdenum with small amounts of corrosion-resistant tantalum, and thereby combines…

PLANSEE Tantal Certified by EICC as „Conflict-Free“

Sustainability is an integral part of PLANSEE purchasing policy. The socially and environmentally responsible procurement of raw materials is set in the Code of Conduct. Strict purchasing guidelines ensure that no materials are obtained from conflict-affected areas.

The use of tantalum raw materials from ethically acceptable sources has now been confirmed by the certificate of the Electronic Industry Citizenship Coalition (EICC). The decree covers all steps of material production.

The audit as…

Thorium-free TIG welding electrodes gain in popularity

Not only health considerations, but also additional costs for the packaging of radioactive thorium-containing welding electrodes lead more and more PLANSEE customers to switch to thorium-free alternatives.

Tungsten electrodes contain different doping agents such as thorium oxide, lanthanum oxide or cerium oxide. These increase the heat resistance of the electrode and reduce the electron work function. Thus, the electrons release themselves from the tungsten electrode’s atomic orbit using less energy and…

More Releases for CIGS

CIGS Solar Cells Market Is Gaining Huge Growth in Upcoming Years

The "Global CIGS Solar Cells" intelligence report, just published by USD Analytics, covers insurers' micro-level study of important market niches, product offers, and sales channels. To determine market size, potential, growth trends, and competitive environment, the Global CIGS Solar Cells provides dynamic views. Both primary and secondary sources of data were used to generate the research, which has both qualitative and quantitative depth. Several of the major figures the study…

Cigs Thin-Film Solar Panel Market Research Trends Analysis

Sunlight is converted into electrical energy using a thin film solar cell called a CIGS, which stands for copper indium gallium selenide. With electrodes on the back and front to gather current, CIGS thin film solar cells are created by depositing a thin layer of indium, copper, selenide, and gallium on a plastic backing or glass. Since CIGS absorbs sunlight strongly and has a high absorption coefficient, a thin sheet…

CIGS CIS Solar Cells Module Market Type, Share, Size, Analysis, Trends, Demand

CIGS/CIS Solar Cells Module Market and enables market participants to establish a presence in the sector. To aid organisations in preparing for the challenges ahead, it identifies crucial market factors such as drivers, restraints, trends, and opportunities. It offers a regional study of the CIGS/CIS Solar Cells Module market to identify the biggest possibilities around the world. Along with company profiles of the top companies active in the CIGS/CIS Solar…

CIGS Thin Film Solar Cell Market Growth Analysis 2017- 2022

Here comes the New Version of CIGS Thin Film Solar Cell Market Research Report is a core market research report in this current market.This report majorly discuss the global and regional market, major manufacturers and segment market details various classifications and mode of applications.

Sample copy of report contact at: Sales@1MarketResearch.com

Related Reports Visit at: https://www.1marketresearch.com

Top Manufacturers which covers in this report:

AVANCIS

Ascent Solar

Daiyang Metal

Flisom

Global Solar

HelioVolt

Honda Soltec

ISET(International Solar Electric Technology, Inc)

LG Innotek

Miasole

Nano Solar

Samsung…

CIGS Market 2017 - Manz, Stion, Hanergy, Solibro, Miasole, Avancis, Solar Fronti …

MarketReports.Biz, recently published a detailed market research study focused on the "CIGS Market" across the global, regional and country level. The report provides 360° analysis of "CIGS Market" from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global CIGS industry, and estimates the future trend of CIGS market on the basis of this…

CIGS Thin-Film Solar Cells Market Will Continue to Grow by 2026

CIGS stands for copper indium gallium selenide, it is a thin film solar cell that is used to convert sun rays into electrical energy. CIGS thin film solar cells are manufactured by the process of depositing a thin layer of indium, copper, selenide and gallium on plastic backing or glass, having electrodes on the back and front to collect current. CIGS has a high absorption coefficient and absorbs sunlight strongly,…