Press release

Thorium-free TIG welding electrodes gain in popularity

Not only health considerations, but also additional costs for the packaging of radioactive thorium-containing welding electrodes lead more and more PLANSEE customers to switch to thorium-free alternatives.Tungsten electrodes contain different doping agents such as thorium oxide, lanthanum oxide or cerium oxide. These increase the heat resistance of the electrode and reduce the electron work function. Thus, the electrons release themselves from the tungsten electrode’s atomic orbit using less energy and so the light arc ignites more easily.

PLANSEE offers various types of tungsten electrodes, which comply to international standard which are marked with uniform color codes. In the past, red-marked tungsten electrodes containing thorium, served as the standard for a long time. PLANSEE is now launching an educational campaign demonstrating the advantages of modern electrode materials.

Thorium is a weakly radioactive element with a low radiation range, which poses no direct threat to humans nor the environment, as long as it is integrated into the solid metal matrix of the electrode. During the production and use of the electrodes, dust or fumes containing thorium develop which accumulate in the lungs and can cause a health risk. Thorium-free electrodes such as the lanthanum-containing WL15 (color code gold) have proven themselves in practical use. They are especially recommended because of improved ignition properties and higher wear-resistance.

- Excellent ignition and re-ignition properties

- High wear resistance

- Constant light arc quality

- Long service lifespan

Legal regulations for the handling of thorium-containing materials, lead to high costs of production, packaging (to meet the radiation limits according to UN 2909), shipping and disposal. These concern all stakeholders along the value chain, from manufacturers to the retailer to the consumer, and can be easily avoided by a transition to thorium-free alternatives.

PLANSEE invites all customers to test the performance of thorium-free TIG welding electrodes. The new web shop at www.plansee-express.com offers the entire range at a very attractive price.

For more information, please visit www.plansee.com. Or contact PLANSEE at welding@plansee.com or +43 5672 / 600-2935

PLANSEE High Performance Materials (HPM) is a world-leading manufacturer of products made from refractory metals and metallic composite materials. The privately owned company has been manufacturing innovative powder-metallurgically processed high-performance materials for over 85 years, and covers the whole production process, right from the raw material to the finished product. The company employs materials experts, product developers and local technical sales staff to provide customers all over the world with all the help and assistance they require.

PLANSEE SE

Metallwerk-Plansee-Str. 71

6600 Reutte / Austria

+43 5672 600-0

info@plansee.com

www.plansee.com

Contact person:

Dr. Nicole Peter

+43 5672 600-2080

nicole.peter@plansee.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Thorium-free TIG welding electrodes gain in popularity here

News-ID: 149796 • Views: …

More Releases from PLANSEE SE

More efficient manufacturing of ceramic coatings: no problem thanks to PLANSEE's …

Hard and extremely durable: ceramic coatings make an ideal protective layer for tools and components. To date, ceramic and brittle materials could only be deposited by means of the reactive magnetron sputtering method, in part because of the lack of an appropriate fixing system for arc evaporation. But now PLANSEE has developed a suitable fixing system for ceramic and brittle composite materials. Using an integrated carrier plate and a cathode…

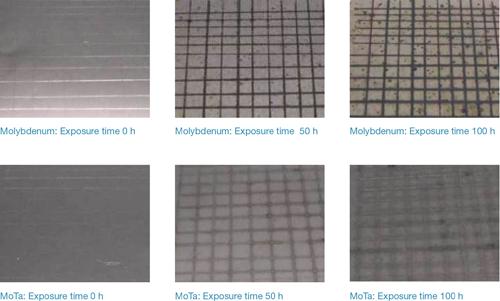

Molybdenum-tantalum: The corrosion-resistant material for CIGS solar cells.

Thanks to its good adhesion to glass and a high electrical conductivity, molybdenum is the back contact material in CIGS solar cells. However, exposed to corrosive atmospheres molybdenum can be prone to oxidation. In order to avoid negative effects during the manufacturing process and the solar module operation, PLANSEE has developed a material with improved corrosion resistance.

The company alloys pure molybdenum with small amounts of corrosion-resistant tantalum, and thereby combines…

The influence of sputtering targets on the manufacturing costs and efficiency of …

The sputtering process is the most important technique for material deposition in CIGS-manufacturing. With innovative sputtering targets CIGS producers can significantly reduce their production costs.

Manufacturers of sputtering targets like PLANSEE have two approaches to reduce CIGS module manufacturing costs: In order to lower the material consumption by a better target utilization PLANSEE introduced the new monolithic and dogbone rotary target designs. With MoNa the company offers a new material alloy…

PLANSEE Tantal Certified by EICC as „Conflict-Free“

Sustainability is an integral part of PLANSEE purchasing policy. The socially and environmentally responsible procurement of raw materials is set in the Code of Conduct. Strict purchasing guidelines ensure that no materials are obtained from conflict-affected areas.

The use of tantalum raw materials from ethically acceptable sources has now been confirmed by the certificate of the Electronic Industry Citizenship Coalition (EICC). The decree covers all steps of material production.

The audit as…