Press release

Guyson ‘Powder Flush’ For Cleaning Additive Manufactured Medical Implants

Industrial finishing equipment manufacturer Guyson International has focused its engineering expertise in solving a crucial problem during additive manufactured orthopaedic implant manufacture. The new Guyson ‘Powder Flush’ has been designed to specifically flush residual additive manufacturing (AM) powders from medical implant trabecular structures, which aid the interlocking human bone growth into the implant.Increasingly the world’s orthopaedic manufacturers are turning to additive manufacturing to drive the long term change in the increased complexity of medical implant design and demand for tailor made patient-specific solutions (rather than one-size-fits-all) with the change in manufacturing from subtractive to additive techniques, with all the benefits that can bring.

These new additive manufactured orthopaedic implants are typically made by SLS, SLM or EBM processes (Selective Laser Sintering, Selective Laser Melting or Electron Beam Melting) from Titanium powders in the size range of 5 to 45 micron for the SLS and SLM processes; and utilising 45 to 90 micron for EBM. After manufacture, the implants then have the bulk of the residue powder removed from the build block with brushes and vacuum’s, sometimes followed with an air-wash or blast process to remove any semi-adhered powder particles, but because of the nature of the porous trabecular structures, small residues of powder are often still trapped inside the component and this must be removed. This is where the Guyson Powder Flush process excels.

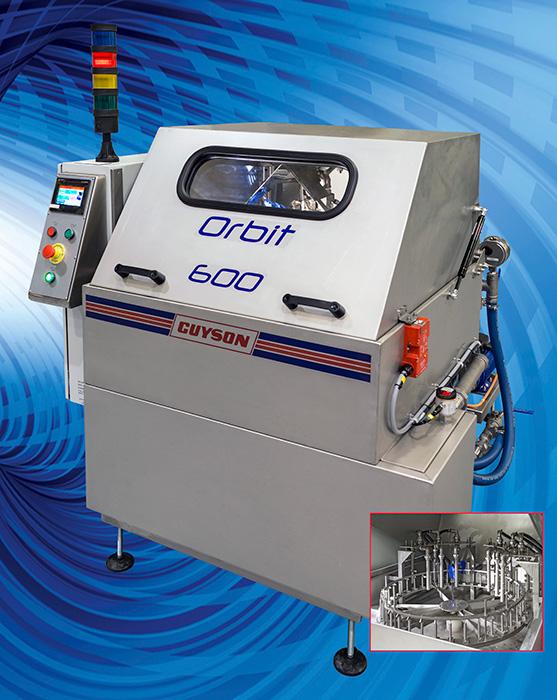

The Guyson ‘Powder Flush’ is based on the company’s Orbit 600 rotary basket spray wash unit, built in full stainless steel 304 construction, fitted with a 100 litre insulated tank and hot spray flushing facilitated through a high flow rate and pressure pump fitted with viton seals. The machine offers directed jets for powerful component flushing followed by compressed air-wash. A PLC/HMI control panel to the left of the machine provides data monitoring and timed pre- heat function ensuring accurate and repeatable process operation. LED interior lighting and a double glazed viewing window, in the lid, facilitates visual checks on parts in process.

In operation the implants are individually or batch loaded on none contaminating fixtures presenting the work piece to the directed flushing jets in close proximity to the trabecular surface thus ensuring thorough powder removal. Timed electronic door interlocks prevent the door opening during operation and until hot steam has dissipated at the end of the process time. Also being generally installed in a production cell, the machine is equipped with process alarm signals with audible and visual cues via an Andon beacon to show the end of parts process. Completing the system is fluid level sensing and advanced filtration, fitted to the rear of the unit.

Guyson’s Managing Director, Mark Viner states that “This new Powder Flush unit adds to the already extensive portfolio of Guyson products provided for the 3D Print/Additive Manufacturing market. This includes our Euroblast Ex range of ATEX certified blast cabinets for surface finishing exotic metal AM parts, often used in the aerospace and medical markets. The Guyson PRS (Powder Recovery System), which is an automated post processing system, specifically for EBM additive builds, and uses tried and trusted robotic blasting methodology to reveal components and manage the resultant powder in a highly contained blast system, and our ‘Kerry’ branded range of ultrasonic baths and tanks for 3D printed fused deposition modelling (FDM) support removal. Guyson have become the ‘go to’ company for post processing finishing equipment in the 3D Printing marketplace.”

For further information on any of Guyson's products, arrange free component trials or to arrange a site visit from one of our sales engineers to talk through your possible requirements please contact our Customer Service Department by phoning 01756 799911 or emailing info@guyson.co.uk

Guyson International Limited

Snaygill Industrial Estate, Keighley Road,

SKIPTON, North Yorkshire, England BD23 2QR

About Guyson

Guyson International Limited is a privately owned family company with a world- wide reputation for excellence in the design and manufacture of blast finishing, spray wash and ultrasonic cleaning equipment. Formed over eighty years ago, the company is registered to BS EN ISO 9001: 2015 and BS OHSAS 18001:2007, and its head office is located at Skipton, North Yorkshire, in the north of England. Guyson has four international subsidiary companies: Guyson Corporation of the USA, located in Saratoga Springs, New York State; Guyson SA, situated near Paris, France; Guyson Sdn Bhd in Penang, Malaysia; and Guyson CN, in Wuxi, Jiangsu Province, China.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Guyson ‘Powder Flush’ For Cleaning Additive Manufactured Medical Implants here

News-ID: 1859096 • Views: …

More Releases from Guyson International Ltd

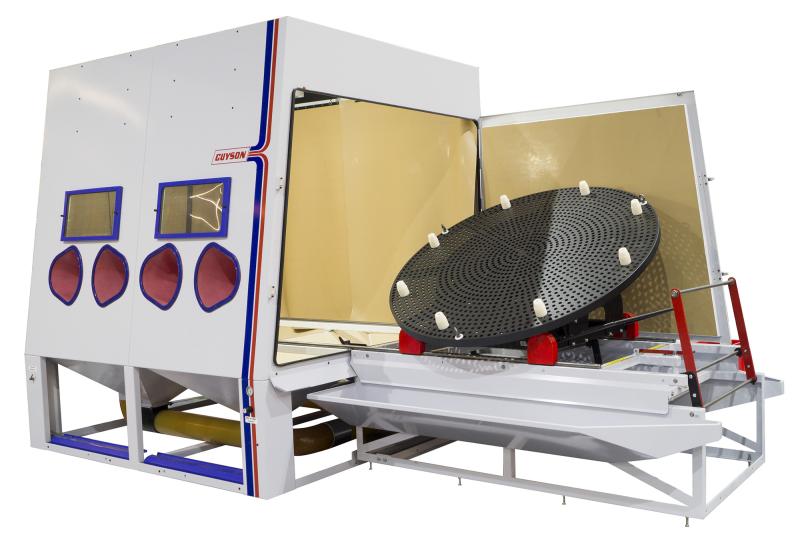

Extra-Large Blast Machine for Blast Etching Aerospace Rings

Guyson International, the UK's foremost industrial finishing equipment manufacturer, has installed a Guyson Euroblast® 2-metre PF (Pressure Fed) blast system into a division of a leading European aerospace company. The extra-large blast cabinet is used to deliver a uniform etched key surface on a range of machined circular aluminium rings prior to bonding.

After blast trails performed at the company's Skipton demonstration centre, a Euroblast 2-metre PF blast system (2.1…

Guyson Twin Spindle Blast Machine for Etching Tubular Components

Guyson International, the UK's leading manufacturer of industrial finishing equipment, has recently manufactured and installed into a UK manufacturing company an automated Multiblast RSB twin spindle blast system for externally blast etching various sizes of tubular components. This new blast system incorporates two rotating blast stations with matching top clamps, to hold the product securely, whilst two vertically traversing blast guns produce a uniform blast etch finish over the length…

Guyson Staff Clock-Up 180 Years!

At Guyson International's Skipton headquarters, Monday 15th August saw rain, much needed, and celebrations, much deserved. Employees from the company's blast and wash division gathered outside to congratulate seven employees who were awarded long service awards. And between them amassed a total of 180 years of service at Guyson, with one, Keith Miller celebrating 50 years of service.

In typical unpredictable UK weather, after so many days of bright hot sunshine,…

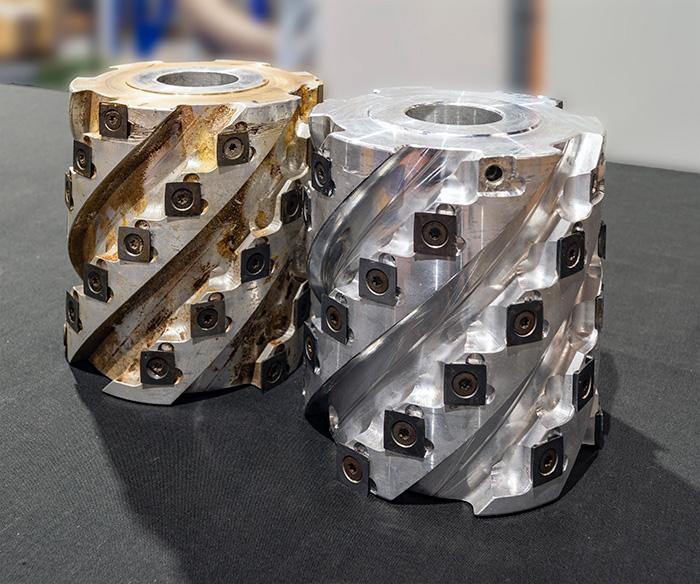

Guyson Equipment Cleans and Maintains Planing and Woodcutting Tools

Guyson International, one of the UK's leading manufacturers of industrial finishing equipment, recently delivered a KS450 ultrasonic cleaning tank and a Formula 1200 benchtop bead blast cabinet to RHW (R H Wilson (Lakes) Ltd.) of Kirkby Stephen, a leading timber importer and supplier, for cleaning and maintaining their wood cutting and planing tools.

The problem was how best to clean 'helical planer blocks' to remove a build-up of pitch, sap, resin…

More Releases for Powder

Polyolefin Powder Market, By Type (Polyethylene Powder, Polypropylene Powder),Tr …

Data Bridge Market Research analyses the polyolefin powder market will exhibit a CAGR of 6.00% for the forecast period of 2022-2029 and is expected to reach the USD 11.79 billion by 2029.

View Detailed Report: https://www.databridgemarketresearch.com/reports/global-polyolefin-powder-market

Polyolefin is a polymer made from the simple monomer olefin, and its powder is made up of crystalline polyolefin made from olefins. Paper coating, ink and paint formulation, and injection moulding are just a few of the applications…

Nano Ceramic Powder Market: Information by Type (Oxide Powder, Carbide Powder, B …

Nano Ceramic powder is nanoparticles which are inorganic solids made up of oxides, ceramics, carbonates, and carbides. The Nano-Ceramic powder has a growing market as they are very useful due to its very small size.

Nano Ceramic powder is strong and the strength of these powder is similar to steel. They exhibit strength at high temperatures. They are more resistant to chemical situations than other metals. There is some ceramic powder…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Global Egg Powder Market Status, Industry Player (Egg Powder, Egg Yolk Powder, E …

An up-to-date research report has been disclosed by Market Research Hub highlighting the title “Global Egg Powder Market Increasing Consumption of Whole Egg Powder to be Observed in the Coming Years” which provides an outlook for current market value as well as the expected growth of Egg Powder during 2018-2025. The report studies the casing heads market worldwide, especially in North America, China, Europe, Southeast Asia, Japan and India, with…