Press release

Automated assembly: Smooth separation and secure transport of PCB

cab exhibits at the Productronica devices for the electronics production. MAESTRO 6 enables stress-free cutting of pre-scored aluminum PCB up to 1,500 mm in length. In the matter of transporting PCB in fully automated production lines, the widths of series 800 magazines are set motor-driven by unloaders or AIVs. hall A3, booth 305Smooth PCB separation

In the field of PCB separation, devices of the MAESTRO cab series cut pre-scored PCB of different lengths and materials with a minimum of mechanical stress. The MAESTRO 6 has been developed for applications with materials FR4, CEM3 or aluminum in lengths up to 1,500 mm. To adjust the blades and check their parallelism, a dial gauge is assembled to the carriage. MAESTRO 6 has its carriage power unit located directly behind the linear blade. This crucially simplifies the separation and removal of PCB. The height of the table supporting the PCB can be adjusted ergonomically.

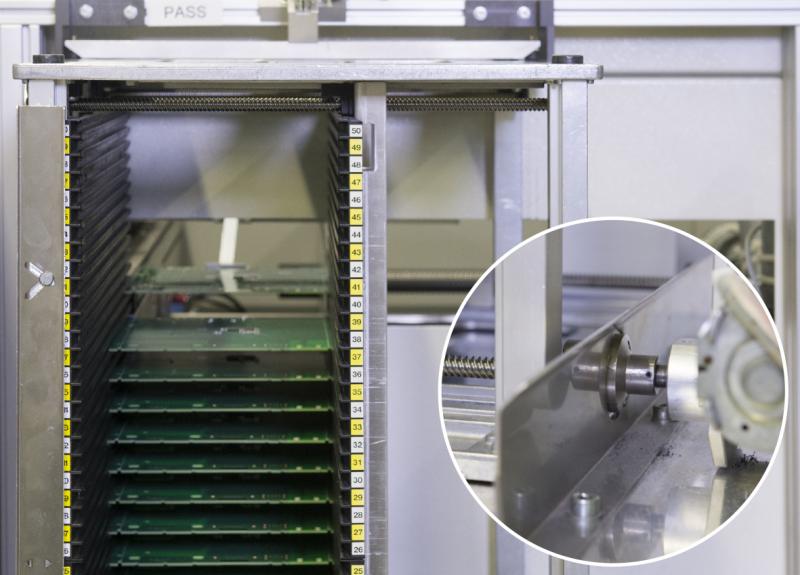

Secure PCB transport in magazines

Assembly facilities of the latest generation are individually adapted several times a day. AIVs load or unload magazines autonomously on stations. To transport different PCB sizes, the magazines have to be constantly adjusted to new widths. When a series 800 cab magazine is inserted in an unloader, a contact is triggered. The side wall moves to a defined reference spot. It then adjusts to the width of the feeding conveyor belt. It is not necessary to stock pre-adjusted magazines. A magazine provides space to insert up to 50 PCB.

Presscontact: Guntram Stadelmann, cab Produkttechnik GmbH & Co KG, Wilhelm-Schickard-Str. 14, 76131 Karlsruhe, Phone: +49 721 6626-285, Fax: +49 721 6626-249, Email: g.stadelmann@cab.de

About: cab is Europe’s leading manufacturer of devices and systems to label individual components, units, products and packaging. Healthy global growth, both technical and functional lead and competent customer support are prior goals of the company. There are 400 employees in Germany and in seven subsidiaries abroad as well as 820 distribution partners in more than 80 countries to meet the targets. www.cab.de/en

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Automated assembly: Smooth separation and secure transport of PCB here

News-ID: 1844125 • Views: …

More Releases from cab Produkttechnik GmbH & Co KG

Smart, flexible, cost-effective - print and apply solutions @LogiMAT 2026

Label printing systems by cab have been enabling reliable marking for more than 50 years. Industrial companies appreciate the wide range of possibilities in incoming goods and stock, picking and packing, transport and shipping. Smart and cost-effective options will complement tried and tested marking disciplines at the cab booth.

cab will be presenting labeling heads designed for applying pre-printed self-adhesive labels fully automatically in linear or rotary plants, synchronous to the…

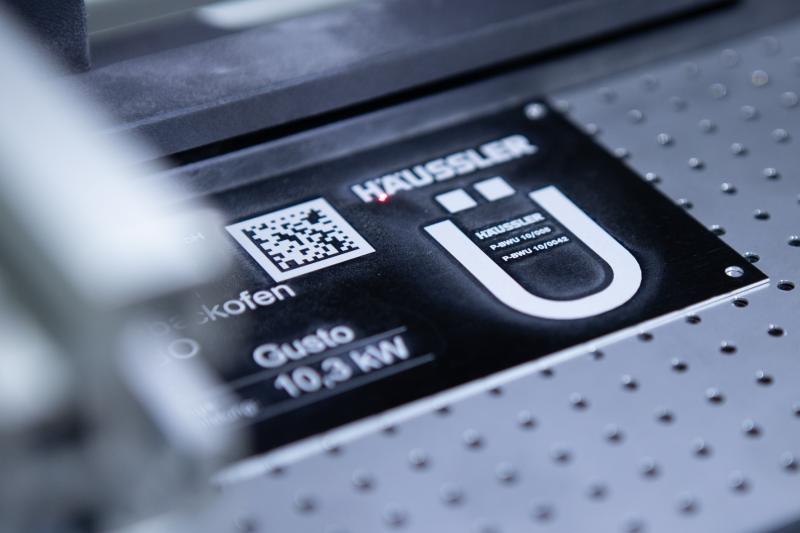

Tradition meets modern - Typeplate marking in a baking village

Karl-Heinz Häussler deals with grinding, kneading and baking. In the company's own baking village, around 100 employees design, manufacture and sell high-quality woodburning ovens and cookers, dough kneading machines, pasta makers and grain mills. Hobby bakers and professionals find guidance and inspiration in baking lessons and seminars. Every unit circulated by Häussler must be clearly identified in accordance with industry regulations. The typeplates are marked in reliable manner by cab…

cab and LRS unveil breakthrough label printing integration

cab and LRS have announced a major advancement in industrial label printing. As of the latest firmware 5.47.5 release, cab printers now fully support VPSX® bi-directional PJL delivery - unlocking a new era of precision, reliability, and flexibility for high-volume labeling environments.

This integration empowers organizations to streamline operations with intelligent label recovery and reprint capabilities. Whether due to a power outage or operator error, large batches of labels…

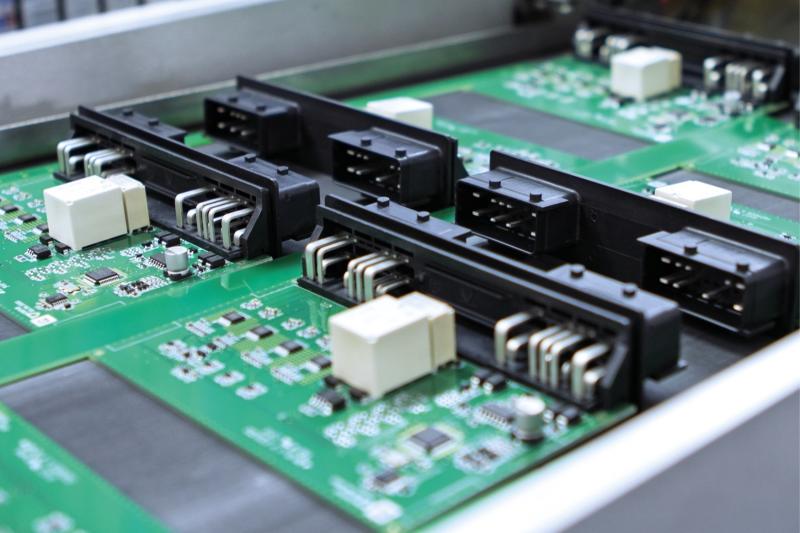

PCB separation and transport at Bavaria Digital Technik

Pfronten in the geographical Allgäu region, gateway to the Alps: This is where BDT develops, manufactures and distributes electronic components, assemblies and systems ready-for-use in data acquisition, recording and control technology. BDT stands for Bavaria Digital Technik GmbH. The company accompanies many customer projects from the initial idea to fully assembled delivery, whether it is prototyping or serial manufacture, hardware or software, project planning, mechanical engineering, testing, approval, logistics or…

More Releases for PCB

Victory PCB Showcases High-Quality Double-Sided PCB Solutions for Modern Electro …

Victory PCB highlights the performance, flexibility, and cost-effectiveness of its double-sided printed circuit boards, designed to meet the demands of mid-complexity electronic systems.

Victory PCB, a professional printed circuit board manufacturer, continues to support modern electronics development through its high-quality double-sided PCB manufacturing solutions [https://www.victorypcb.com/products-category/double-sided-pcbs.html]. Designed to balance performance, reliability, and cost efficiency, Victory PCB's double-sided printed circuit boards are widely used across industries that require greater circuit density without the…

Victory PCB Expands Global Reach with Industry-Leading PCB Manufacturing & Assem …

Image: https://www.abnewswire.com/upload/2025/06/aa56d146ab76e34a4f335137dad3dd49.jpg

Victory PCB [https://www.victorypcb.com/], a global leader in printed circuit board (PCB) manufacturing and assembly, continues to set new benchmarks in high-quality PCB production, fast delivery, and customer service excellence. With a legacy of 19 years of innovation and precision manufacturing, Victory PCB is powering the next generation of industries, from automotive and medical equipment to aerospace and advanced communication devices.

Located in the heart of Shenzhen's modern Industrial Park, Victory…

Victory PCB: Pioneering Excellence in Global PCB Manufacturing and Assembly

Image: https://www.abnewswire.com/upload/2025/01/fabf105f8930f331e50cb1ca439637fe.jpg

Victory PCB [https://www.victorypcb.com/] is a renowned global manufacturer of PCBs and assembly services, recognized worldwide for its exceptional precision, innovation, and commitment to quality. With a client base exceeding thousands across various sectors, including automotive, aerospace, medical, industrial automation, and communication technologies, PCB solutions are tailored to meet each client's needs.

With centers covering as much as 30,000 square meters, Victory PCB employs over 450 staff dedicated to producing high-quality…

Victory PCB: Redefining Global Excellence in PCB Manufacturing and Assembly

Image: https://www.abnewswire.com/upload/2025/01/986e29984b844645f2a99a0a5e93a4c8.jpg

Having almost 20 years of expertise in producing and assembling printed circuit boards (PCBs), Victory PCB has established a solid reputation for providing high quality products, creative solutions, and consistent customer satisfaction. Victory PCB [https://www.victorypcb.com/], located in a contemporary 30,000-square-meter facility within Shenzhen's tech district, merges deep expertise with cutting-edge technology to manufacture products that bolster top industries worldwide. Relying on more than 1,000 clients and 80% of its…

Victory PCB Emerges as a Global Leader in PCB Manufacturing

Victory PCB has been delivering custom PCB solutions to global customers since 2005.

Image: https://www.abnewswire.com/uploads/3daf3e2d61300e7406f7fb61c56726fc.png

Victory PCB [https://www.victorypcb.com/], a professional printed circuit board (PCB) manufacturer established in 2005, is setting new standards in the global electronics industry with its commitment to top-quality, high-precision, and high-density PCB solutions. The solutions offered by Victory PCB, which exports 80% of its products worldwide, bridge the gap between concept and reality for clients in a variety…

PCB Ceramic Substrate Market Size, Share and Forecast By Key Players-Panda PCB T …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- According to the MRI Team's Market Research Intellect, the global PCB Ceramic Substrate market is anticipated to grow at a compound annual growth rate (CAGR) of 13.62% between 2024 and 2031. The market is expected to grow to USD 21.58 Billion by 2024. The valuation is expected to reach USD 52.73 Billion by 2031.

The PCB ceramic substrate market is experiencing robust growth, fueled by the rising demand…