Press release

PCB separation and transport at Bavaria Digital Technik

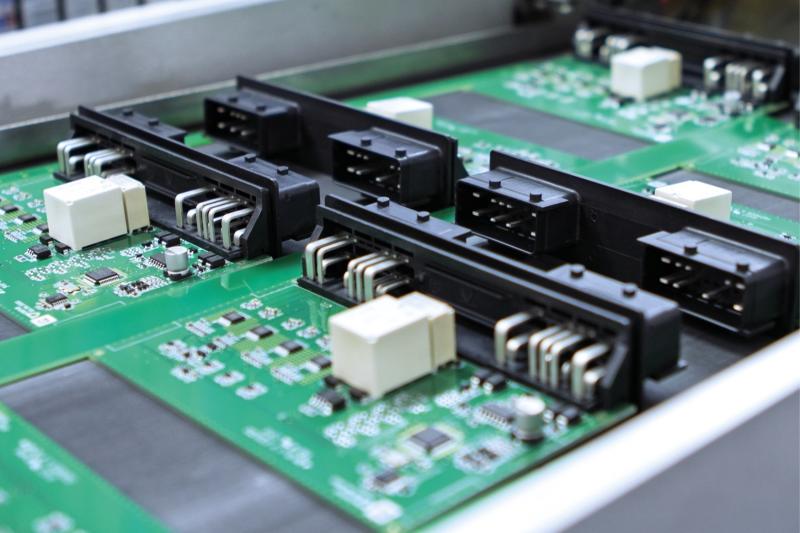

Pfronten in the geographical Allgäu region, gateway to the Alps: This is where BDT develops, manufactures and distributes electronic components, assemblies and systems ready-for-use in data acquisition, recording and control technology. BDT stands for Bavaria Digital Technik GmbH. The company accompanies many customer projects from the initial idea to fully assembled delivery, whether it is prototyping or serial manufacture, hardware or software, project planning, mechanical engineering, testing, approval, logistics or service. At the warehouse, about 50 cab series 700 magazines are stacking PCB panels for safe transport and further steps of manufacture. Within the processing and assembly lines, cab MAESTRO 5 units are separating PCB precisely with low stress.PCB transport

Reliable processes, ruggedness, stability and easy handling are major requirements posed by BDT on the use of PCB magazines. cab units can do all these. They are made of electrically conductive plastics. Torsion-resistance supports continuous operation. Low weight and tool-rounded edges enable the magazines been carried by hand without risk. When operating different PCB sizes, the magazines can be aligned to new widths using a toothed belt. For use in plants with higher-level control, in which loaders transport PCB, cab offers magazines whose moveable side walls adjust automatically when being placed onto the loader.

Separation of PCB

In electronics, a panel refers to several PCB arranged on a carrier. It is crucial to minimize mechanical stress when separating the PCB. Sensitive components such as microcontrollers or capacitors must not be damaged. MAESTRO PCB separators operate with low stress thanks to precisely guided circular and linear blades. BDT benefits from the persistence and consistent quality of the assembled PCB.

At BDI, lots of an order can comprise as many as 5,000 PCB. The MAESTRO 5 unit is particularly economical when separating pre-scored PCB in large quantities. A maximum of 15 PCB in multiple-use panels can be separated simultaneously. The number of circular blades and their spacing are selected according to a PCB. Stable and precisely manufactured blade shafts make up top-notch cuts. The circular blades are hardened, grinded and coated with Titanium for high working capacity. BDT employees insert the panels to the MAESTRO 5 guide. It would also be possible to feed panels automatically using a loader or an external conveyor. The base frame of MAESTRO 5 can be adjusted in height for any application. Separated PCB are transported on an integral conveyor.

Cobot, take control!

In further manufacturing steps, robots guide PCB through additional assemblies to BDT end products, such as modules for trailer monitoring in towing vehicles, PLC control in industrial electronics, nerve stimulation in medtech or protocol converters for combined heat and power stations.

Harmonious synergy

Gerd Atzler is responsible for production engineering and maintenance at BDT. He recalls: "We got in contact with cab in 2008. At that time, our incoming goods department had cab label printers in use and had always been satisfied." This led to an extended requirement for the electronics manufacturing department. A PCB separator was needed that met BDT's demands for efficiency and ease of use. "The initial contact," Mr. Atzler adds, "proved to be particularly valuable for us. During the meeting, we quickly got aware of the potential of cab solutions for our processes. We therefore decided to collaborate."

Reliable partners on equal terms

BDT has always been satisfied with the partnership. The units can be handled straightforward, free of complex programming. Durable equipment results in trouble-free manufacturing. Gerold Marsch as a technical consultant and cab's phone support provide competent and quick assistance when needed. "For BDT, cab has long been more than just a supplier," says Mr. Atzler: "A powerful partner on equal terms."

Productronica 2025

cab in Munich will exhibit various devices for PCB separation or transport, added by solutions for PCB labeling. November 18-21, 2025, hall A3, booth 305

Presscontact: Guntram Stadelmann, Marketing / Technical Editing, Phone: +49 721 6626-285, g.stadelmann@cab.de, cab Produkttechnik GmbH & Co KG, Wilhelm-Schickard-Str. 14, 76131 Karlsruhe / Germany

About: cab is Europe's biggest manufacturer of label printing systems. The range of devices includes solutions for marking individual components, units, products or packaging. Healthy global growth, pioneering technologies, products designed according to the needs of operators and the competent support of all customers are prior goals of the company. Employees at locations in eight countries and 850 distribution and service partners around the globe are there to meet the targets.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release PCB separation and transport at Bavaria Digital Technik here

News-ID: 4193569 • Views: …

More Releases from cab Produkttechnik GmbH & Co KG

Smart, flexible, cost-effective - print and apply solutions @LogiMAT 2026

Label printing systems by cab have been enabling reliable marking for more than 50 years. Industrial companies appreciate the wide range of possibilities in incoming goods and stock, picking and packing, transport and shipping. Smart and cost-effective options will complement tried and tested marking disciplines at the cab booth.

cab will be presenting labeling heads designed for applying pre-printed self-adhesive labels fully automatically in linear or rotary plants, synchronous to the…

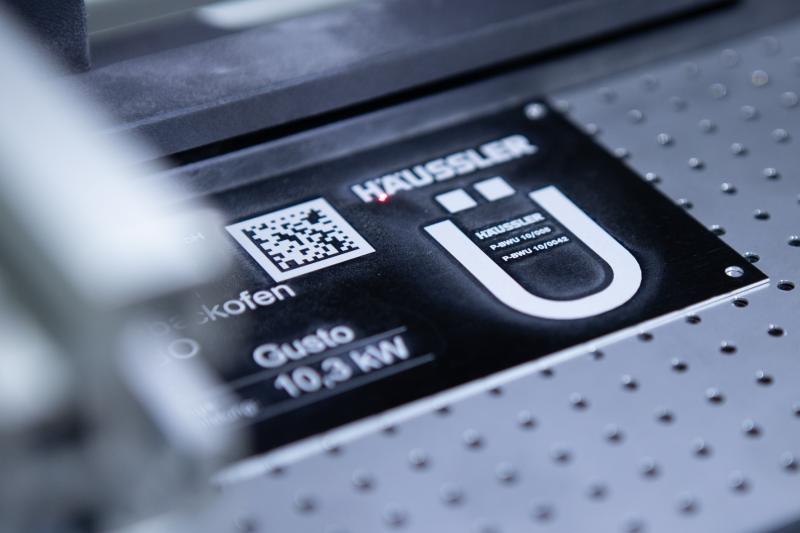

Tradition meets modern - Typeplate marking in a baking village

Karl-Heinz Häussler deals with grinding, kneading and baking. In the company's own baking village, around 100 employees design, manufacture and sell high-quality woodburning ovens and cookers, dough kneading machines, pasta makers and grain mills. Hobby bakers and professionals find guidance and inspiration in baking lessons and seminars. Every unit circulated by Häussler must be clearly identified in accordance with industry regulations. The typeplates are marked in reliable manner by cab…

cab and LRS unveil breakthrough label printing integration

cab and LRS have announced a major advancement in industrial label printing. As of the latest firmware 5.47.5 release, cab printers now fully support VPSX® bi-directional PJL delivery - unlocking a new era of precision, reliability, and flexibility for high-volume labeling environments.

This integration empowers organizations to streamline operations with intelligent label recovery and reprint capabilities. Whether due to a power outage or operator error, large batches of labels…

Marking with labels at Labelexpo / Fachpack 2025

Companies at home in the packaging of industrial and consumer goods value cab print and apply systems because of their manifold possible use and high level of integration into packing lines.

cab has just introduced ROXI, a label dispenser. Printed self-adhesive labels can be dispensed fully automatically in linear and rotary plants. The labels are fed in accordance with the speed of an item as high as 30 meters per minute…

More Releases for PCB

Victory PCB Showcases High-Quality Double-Sided PCB Solutions for Modern Electro …

Victory PCB highlights the performance, flexibility, and cost-effectiveness of its double-sided printed circuit boards, designed to meet the demands of mid-complexity electronic systems.

Victory PCB, a professional printed circuit board manufacturer, continues to support modern electronics development through its high-quality double-sided PCB manufacturing solutions [https://www.victorypcb.com/products-category/double-sided-pcbs.html]. Designed to balance performance, reliability, and cost efficiency, Victory PCB's double-sided printed circuit boards are widely used across industries that require greater circuit density without the…

Victory PCB Expands Global Reach with Industry-Leading PCB Manufacturing & Assem …

Image: https://www.abnewswire.com/upload/2025/06/aa56d146ab76e34a4f335137dad3dd49.jpg

Victory PCB [https://www.victorypcb.com/], a global leader in printed circuit board (PCB) manufacturing and assembly, continues to set new benchmarks in high-quality PCB production, fast delivery, and customer service excellence. With a legacy of 19 years of innovation and precision manufacturing, Victory PCB is powering the next generation of industries, from automotive and medical equipment to aerospace and advanced communication devices.

Located in the heart of Shenzhen's modern Industrial Park, Victory…

Victory PCB: Pioneering Excellence in Global PCB Manufacturing and Assembly

Image: https://www.abnewswire.com/upload/2025/01/fabf105f8930f331e50cb1ca439637fe.jpg

Victory PCB [https://www.victorypcb.com/] is a renowned global manufacturer of PCBs and assembly services, recognized worldwide for its exceptional precision, innovation, and commitment to quality. With a client base exceeding thousands across various sectors, including automotive, aerospace, medical, industrial automation, and communication technologies, PCB solutions are tailored to meet each client's needs.

With centers covering as much as 30,000 square meters, Victory PCB employs over 450 staff dedicated to producing high-quality…

Victory PCB: Redefining Global Excellence in PCB Manufacturing and Assembly

Image: https://www.abnewswire.com/upload/2025/01/986e29984b844645f2a99a0a5e93a4c8.jpg

Having almost 20 years of expertise in producing and assembling printed circuit boards (PCBs), Victory PCB has established a solid reputation for providing high quality products, creative solutions, and consistent customer satisfaction. Victory PCB [https://www.victorypcb.com/], located in a contemporary 30,000-square-meter facility within Shenzhen's tech district, merges deep expertise with cutting-edge technology to manufacture products that bolster top industries worldwide. Relying on more than 1,000 clients and 80% of its…

Victory PCB Emerges as a Global Leader in PCB Manufacturing

Victory PCB has been delivering custom PCB solutions to global customers since 2005.

Image: https://www.abnewswire.com/uploads/3daf3e2d61300e7406f7fb61c56726fc.png

Victory PCB [https://www.victorypcb.com/], a professional printed circuit board (PCB) manufacturer established in 2005, is setting new standards in the global electronics industry with its commitment to top-quality, high-precision, and high-density PCB solutions. The solutions offered by Victory PCB, which exports 80% of its products worldwide, bridge the gap between concept and reality for clients in a variety…

PCB Ceramic Substrate Market Size, Share and Forecast By Key Players-Panda PCB T …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- According to the MRI Team's Market Research Intellect, the global PCB Ceramic Substrate market is anticipated to grow at a compound annual growth rate (CAGR) of 13.62% between 2024 and 2031. The market is expected to grow to USD 21.58 Billion by 2024. The valuation is expected to reach USD 52.73 Billion by 2031.

The PCB ceramic substrate market is experiencing robust growth, fueled by the rising demand…