Press release

Under scrutiny: Automated induction thermography for surface crack testing of forgings

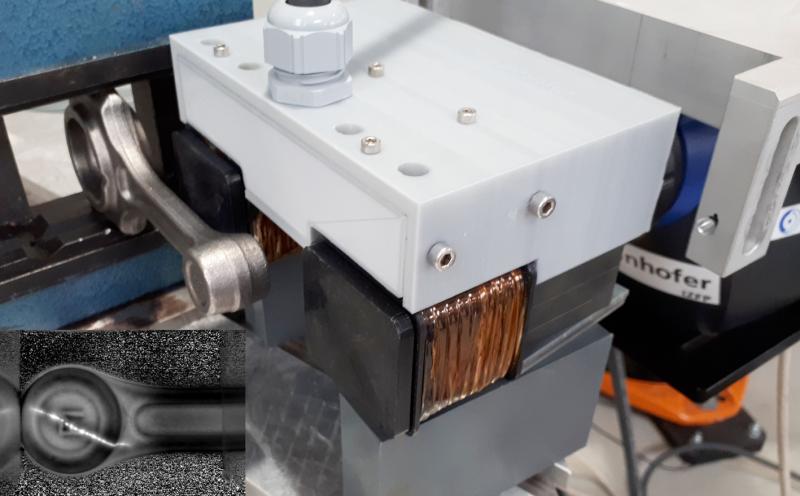

Within the framework of a project funded by the "Arbeitsgemeinschaft industrieller Forschungsvereinigungen" AiF ("Consortium of Industrial Research Associations"), Fraunhofer IZFP scientists investigate the reliability of the automated application of the thermographic crack detection method: After positive validation, this technology is to find better acceptance as an alternative to the established magnetic particle inspection. Using this method, surface-related defects such as cracks in forged parts can be determined quickly, objectively and in a resource-saving manner while the results can be stored and documented in detail. This study is intended to confirm the increased inspection reliability compared to current standard procedures. The resulting optimized economic efficiency of this new procedure will significantly contribute to the competitiveness of small and medium-sized enterprises (SMEs).Induction thermography* is applied in many industrial sectors where forged or steel components are in use. These include the automotive industry, e.g. car steering systems, petrochemical industry and water supply (steel water pipes). Notwithstanding continuous improvements in the manufacturing processes, failures may occur in the manufactured components, for example also due to pre-material defects. Thus, nondestructive inspection of components where the inspection is performed by one of the established and standardized inspection methods, such as ultrasound for volume defects or magnetic particle inspection** for surface defects, is generally required.

Fully automated inspection with digital product file

In the mentioned AiF project, which is lead-managed by Fraunhofer IZFP, the thermographic crack inspection for the detection of near-surface defects in steel parts is subject to a close scrutiny: On the basis of reliable and resilient investigations scientists of the institute are to test and confirm the potential of this method in comparison to standardized magnetic particle testing. The project results are intended to provide forging plants an economic basis which is to facilitate future decisions in favor of the method. "A major aspect of the project involves the implementation of an automated image analysis for defect detection without human intervention. The recorded thermographic image sequences are automatically analyzed and assessed. After this, the results are stored and provided in the form of a so-called 'digital product file'," explains Dr. Udo Netzelmann, Fraunhofer IZFP’s lead project manager.

Enhanced inspection reliability and reduced inspection times

When comparing fully automated inspection by induction thermography to magnetic particle inspection the Fraunhofer IZFP specialists defined the goal of achieving at least the same level of inspection reliability with at least the same, but ideally reduced inspection times. "By the use of this thermographic method, we expect this to lead to a reduced dependance on the skills of the inspection personnel and, as a consequence, a substantial reduction in rejects. In addition, the test substances used in magnetic particle testing – some of which being harmful to health – are superfluous. Thus, there is no more need to clean the surface and to dispose of the chemicals afterwards," states Udo Netzelmann.

Hence, it will be possible to store and document the raw data of any inspected component as well as the images of the defect indications. Even after longer periods of time conclusions concerning defect sources can be drawn easily. System integrators and suppliers of inspection systems will seriously benefit from the results.

* With this technology, an inductor generates an alternating current in the electrically conductive steel. In case of the induced current strikes a surface crack, it has to make a detour around the crack. Due to ohmic losses the current flow in the component is correlated with material heating up. The current density is changed by cracks, resulting in characteristic defect signatures visible for infrared cameras. The image sequence recorded with the infrared camera can be evaluated in a short time. After pre-processing and automated defect detection, the defect images are displayed.

**In crack detection by magnetic particle inspection, the surface of the component to be inspected is sprayed with a magnetic test medium. In many cases, a fluorescent test medium is used, with a dye attached to the magnetic particles. This dye glows visibly under ultraviolet light, thus marking the crack and its course for the assessment by an inspector. In the aftermath, the test medium usually has to be washed off and disposed of properly.

Head of Corporate Communications / Editorial Notes:

Sabine Poitevin-Burbes | Fraunhofer Institute for Nondestructive Testing IZFP | Phone +49 681 9302-3869 | Campus E3 1 | 66123 Saarbrücken, Germany | www.izfp.fraunhofer.de | sabine.poitevin-burbes@izfp.fraunhofer.de

Further Contact:

Dr. Udo Netzelmann | Fraunhofer Institute for Nondestructive Testing IZFP | Phone +49 681 9302-3873 | Campus E3 1 | 66123 Saarbrücken, Germany | www.izfp.fraunhofer.de | udo.netzelmann@izfp.fraunhofer.de

Cognitive Sensor Systems – Efficient Processes

Fraunhofer IZFP is an internationally networked research and development institute in the field of applied research. Its activities are focused on the development of "cognitive sensor systems" for the nondestructive monitoring of industrial processes and value chains. Major concepts of these technologies are derived from AI research. In addition to pure production processes, the activities cover equally processes from materials and product development, maintenance, repair, and recycling of materials.

The current research focus relates to the development of sensors that are suited to capture production-related microstructural patterns and to merge them in the sense of an individual fingerprint, a so-called "product DNA". In the future, these "digital product files" will open up completely new approaches for the optimization of the individual sectors of a material and product lifecycle.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Under scrutiny: Automated induction thermography for surface crack testing of forgings here

News-ID: 1825436 • Views: …

More Releases from Fraunhofer IZFP

Fraunhofer IZFP at GIFA 2019: Robot-assisted sensor system for the quality monit …

Within the framework of quality monitoring of lightweight construction components intelligent sensor systems become crucial: In many industries, especially in aerospace engineering and automotive industry, the use of forward-looking hybrid designs based on fiber composites and light metals is steadily rising. Material defects in the final product may result in early malfunction, thus, impairing the safe use of the product. From 25-29 June 2019, at the 14th International Foundry Trade…

Smart sensors for efficient processes

Material defects in end products can quickly result in failures in many areas of industry, and have a massive impact on the safe use of their products. This is why, in the field of quality assurance, intelligent, nondestructive sensor systems play a key role. They allow testing components and parts in a rapid and cost-efficient manner without destroying the actual product or changing its surface. Experts from the Fraunhofer IZFP…

More Releases for Inspection

Inspection Drones Market 2032: Advancements, Trends, and AI-Enabled Industrial I …

The Inspection Drones Market size was valued at USD 8.90 Billion in 2024 and the total Inspection Drones revenue is expected to grow at a CAGR of 12.9% from 2025 to 2032, reaching nearly USD 23.50 Billion.

Inspection Drones Market Overview:

The Inspection Drones Market has garnered strong attention from industries that require rapid and accurate evaluation of assets such as power lines, wind turbines, pipelines, bridges, and industrial installations. These drones…

Railway Inspection Services Market Outlook : Solutions, Inspection Vehicles & Sy …

Railway inspection is the practice of examining rail tracks for flaws that lead to catastrophic failures causing accidents. According to the U.S. Federal Railroad Administration Office of Safety Analysis, track defects are the second cause of railway accidents in U.S. Some of the reasons causing track defects are shear stresses, wheel/rail contact stresses, thermal stresses, residual stresses, and dynamic effects. Moreover, due to contact stresses defects such as tongue lipping,…

Surface Inspection Market: Surface Inspection Market to Grow to USD 10.29B by 20 …

Surface Inspection Market Scope:

Key Insights : Surface Inspection Market size was valued at USD 5.02 billion in 2022 and is poised to grow from USD 5.44 billion in 2023 to USD 10.29 billion by 2031, growing at a CAGR of 8.3% in the forecast period (2024-2031).

Discover Your Competitive Edge with a Free Sample Report :https://www.skyquestt.com/sample-request/surface-inspection-market

Access the full 2024 Market report for a comprehensive understanding @https://www.skyquestt.com/report/surface-inspection-market

In-Depth Exploration of the global…

Thermal Drone Inspection Market Soars as Industries Embrace Efficient and Safe I …

The global thermal drone inspection market is estimated to exceed US$ 282.4 million by the end of 2023, by growing at an impressive CAGR of 13.4% over the assessment period of 2023-2033.

The deployment of thermal cameras with infrared sensors and high quality image processors has significantly expanded the applications of the thermal drones. They can be utilized in various industries, for instance, firefighting, search & rescue, ariel utility and advanced…

beXel launched different inspection modules to improve inspection quality

beXel launched a Variety of modules to facilitate the inspection process and provide smart solutions for the customers such as

(Drops Inspection, Job order management, Lifting Inspection, NDT inspection, Tubular Inspection, Desktop Offline App).

A quality inspection involves measuring, examining, testing, or gauging various characteristics of a product and comparing those results with specified requirements to determine whether there is conformity.

Quality Control (QC) is critical to build and deliver products that meet…

Carlsbad, CA Mold Inspection and Asbestos Testing Services Offered by Murrieta M …

Carlsbad, CA, December 16, 2019 – EZ Mold Inspections continues expanding its service area in San Diego County and now provides asbestos testing and mold inspections in Carlsbad, California. The inspection company is based in the Murrieta-Temecula area. The company now serves nine areas in Riverside County and two cities in San Diego County including Oceanside, CA and Carlsbad, CA.

With more than two decades of experience in real estate and…