Press release

Fraunhofer IZFP at GIFA 2019: Robot-assisted sensor system for the quality monitoring of hybrid parts

Within the framework of quality monitoring of lightweight construction components intelligent sensor systems become crucial: In many industries, especially in aerospace engineering and automotive industry, the use of forward-looking hybrid designs based on fiber composites and light metals is steadily rising. Material defects in the final product may result in early malfunction, thus, impairing the safe use of the product. From 25-29 June 2019, at the 14th International Foundry Trade Fair in Düsseldorf, Fraunhofer IZFP scientists will introduce a robot-assisted sensor system for the nondestructive inspection of hybrid cast components, which can easily be integrated into the quality monitoring of production processes (hall 13, booth A34).Time-consuming destructive inspection methods used in quality assurance result in enormous costs, as the product is damaged or even destroyed during the process. Moreover, as a consequence of destructive inspections being randomized, process disturbances are often not detected until a considerable amount of scrap has already been produced. Thus, nondestructive methods offer an alternative and, after adequate realization, even a long-term substitute for destructive methods. The Fraunhofer Institute for Nondestructive Testing IZFP in Saarbrücken inspects components or parts already during the manufacturing process, without damaging the material itself or changing the surface and properties.

Cognitive sensor systems for inline quality monitoring of production processes

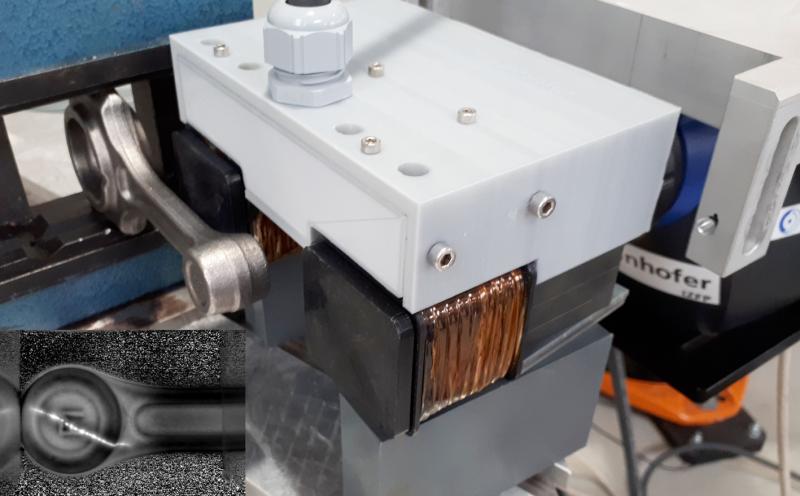

In the context of industry 4.0 the automated operation of intelligent nondestructive sensor systems is crucial for the safeguarding of maximum product quality during production processes: At this year’s GIFA our experts present a robot-based sensor system for quality monitoring, which can easily be integrated into production processes. A possible application of such systems will be demonstrated by the robot-assisted inspection of hybrid cast samples. These are die-cast aluminum ingots reinforced by a metal insert on the inside. The integrated eddy current inspection method allows the validation of quality characteristics such as position or integrity of the insert.

The benefits of robot-based inspection with eddy current compared to conventional computed tomography relate to the uncomplicated inspection with significantly less necessary safety precautions as well as to the assessment of relevant quality features: This preserves resources, reduces costs and helps to strengthen the competitive position of producers. This Saarland research institute is endued with decades of experience and know-how in the field of combination and automatization of nondestructive inspection methods for production lines.

Head of Corporate Communications / Editorial Notes:

Dipl.-Übers. Sabine Poitevin-Burbes

Fraunhofer Institute for Nondestructive Testing IZFP

Campus E3 1

66123 Saarbrücken, Germany

Phone +49 681 9302-3869

www.izfp.fraunhofer.de

sabine.poitevin-burbes@izfp.fraunhofer.de

Cognitive sensor systems – Efficient Processes

Fraunhofer IZFP is an internationally networked research and development institute in the field of applied, industrial-grade research. Its activities are focused on the development of "cognitive sensor systems" for the nondestructive monitoring of industrial processes and value chains. Major concepts of these technologies are derived from AI research.

In addition to pure production processes, the activities cover equally processes from materials and product development, maintenance, repair, and recycling of materials.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Fraunhofer IZFP at GIFA 2019: Robot-assisted sensor system for the quality monitoring of hybrid parts here

News-ID: 1779273 • Views: …

More Releases from Fraunhofer IZFP

Under scrutiny: Automated induction thermography for surface crack testing of fo …

Within the framework of a project funded by the "Arbeitsgemeinschaft industrieller Forschungsvereinigungen" AiF ("Consortium of Industrial Research Associations"), Fraunhofer IZFP scientists investigate the reliability of the automated application of the thermographic crack detection method: After positive validation, this technology is to find better acceptance as an alternative to the established magnetic particle inspection. Using this method, surface-related defects such as cracks in forged parts can be determined quickly, objectively and…

Smart sensors for efficient processes

Material defects in end products can quickly result in failures in many areas of industry, and have a massive impact on the safe use of their products. This is why, in the field of quality assurance, intelligent, nondestructive sensor systems play a key role. They allow testing components and parts in a rapid and cost-efficient manner without destroying the actual product or changing its surface. Experts from the Fraunhofer IZFP…

More Releases for Institute

Astrobiology Market is Booming Worldwide | SETI Institute, Max Planck Institute, …

HTF MI recently introduced Global Astrobiology Market study with 143+ pages in-depth overview, describing about the Product / Industry Scope and elaborates market size (2025-2032). The market Study is segmented by key regions which is accelerating the marketization. At present, the market is developing its presence.

Major Companies in Astrobiology Market are: NASA, ESA, Blue Origin Research, SpaceX Research, SETI Institute, Max Planck Institute, European Astrobiology Network, Harvard Origins,…

Firestar Institute launches world's first AI Interview training institute - "Sta …

Image: https://www.abnewswire.com/upload/2025/10/7b06d6a06aeca24606ce4205234b8972.jpg

Cambridge, UK - In a bold move set to redefine how candidates prepare for job interviews, the newly launched Firestar Institute announces itself as the world's first AI interview training institute, offering a world-class course developed by a Cambridge-based team. With its provocative rallying cry - "STAR is dead" - Firestar introduces the AI-FIRESTAR Trademark method, a revolutionary upgrade to the traditional STAR technique, built specifically for interviews scored…

Flying Goose Aviation Institute - The Best Aviation Institute in Kochi & Ernakul …

Kochi, Kerala - Flying Goose Aviation Institute proudly stands as the best aviation institute in Kochi and Ernakulam, offering world-class aviation courses in Kerala with a strong focus on industry-relevant training and 100% placement assistance.

As a leading aviation academy in Kochi, we provide top-tier programs, including BBA Aviation courses in Ernakulam, airport management courses in Kochi, and specialized training in cabin crew, ground staff, and aviation hospitality. Our state-of-the-art infrastructure,…

Health Coaching Market Set to Witness Significant Growth by 2025-2032 | Sears We …

Health Coaching Market Analysis - 2025-2032:

Coherent Market Insights has released a new report titled "Health Coaching Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2032 (Version 2025)." This report provides an in-depth analysis of the Health Coaching industry, featuring insights on market trends and performance. It also includes a thorough examination of competitors, regional dynamics, and the latest advancements within the market.

Coverage of the Health Coaching Market:

The report provides…

Digital Marketing Course Institute

Brandveda triumphs with more than 50,000 success stories

New Delhi [India], September 7: Brandveda, established in 2013 and one of the leading digital marketing institutes in India, has successfully trained and developed over 50,000 students, professionals and entrepreneurs to become industry leaders through seminars, corporate and educational workshops, free-of-cost workshops, online webinars and free courses.

The institute has also collaborated with leading universities and colleges to conduct seminars and workshops as part…

Oral Vaccine Market SWOT Analysis by Key Players- Sanofi, Lanzhou Institute, Ser …

A new business intelligence report released by HTF MI with title "Global (United States, European Union and China) Oral Vaccine Market Research Report 2019-2025" is designed covering micro level of analysis by manufacturers and key business segments. The Global (United States, European Union and China) Oral Vaccine Market survey analysis offers energetic visions to conclude and study market size, market hopes, and competitive surroundings. The research is derived through primary…