Press release

Factory Modelling Prevents Painful Problems

Factories have a life that spans decades, so it’s no surprise that many Owner/Operators have a wealth of incomplete paper layouts or digital 2D drawings which only document part of the current set-up. As facilities gear up for flexible manufacturing, regularly changing in order to quickly introduce new product lines or the latest equipment, an accurate lifecycle model of a factory becomes vital.Engineering software provider CAD Schroer has recognised this trend, and now offers a factory modelling service as part of its solutions. “Many factories have project-driven engineering departments handling layout design in-house,” explains Bill Wilkins, Technical Sales Manager at CAD Schroer UK. “Where complex production processes run on multiple factory levels, changes require detailed knowledge of what’s already there, how it’s positioned (hard space) and what space is required to move, run and maintain equipment (soft space). When there is spatial complexity, 2D drawings are an invitation to get things wrong or omit important information, which translates into unplanned down-time and expensive re-work if new lines don’t fit into existing spaces.”

Factory Modelling Service Overview:

http://www.cad-schroer.com/Services/Factory_Modelling/

2D to 3D

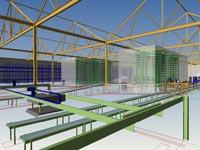

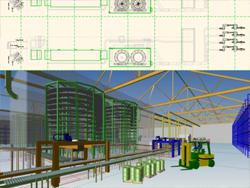

The service speeds up projects, easing the transition between 2D drawings and a 3D factory lifecycle model. Clients can focus on planning changes, rather than on the CAD data needed to proceed. Bill adds, “The model created is based on existing data (scanned drawings, 2D CAD data, 3D machinery models). We report and resolve inconsistencies we find along the way. Where no up-to-date drawings exist, laser scanning can provide the data needed for a model.”

CAD Schroer delivers the factory model and the software needed to plan changes. Users edit project data interactively in the 2D layout or 3D spatial design environment. Hard and soft clash detection and consistency checking ensure accuracy. Easy-to-use 3D walk-through tools visualise plans for internal and external stakeholders.

CAD Schroer is a global software development company and engineering solutions provider, helping to raise the productivity and competitiveness of customers working in manufacturing and plant design, including the automotive sector and its supply chain, the energy sector and public utilities. CAD Schroer has offices throughout Germany, Belgium and the Netherlands, and independent subsidiaries in France, Italy, Switzerland, the United Kingdom and the United States.

CAD Schroer’s product portfolio includes 2D/3D CAD, plant design, factory layout and data management solutions. Customers in 39 countries rely on MEDUSA4®, MPDS4™ and STHENO/PRO® to provide an efficient, flexible and integrated design environment for all phases of product or plant design – cutting costs while raising quality. CAD Schroer emphasises close customer partnerships and supports its clients’ objectives through extensive consultancy, training, development, software support and maintenance services.

Michael Schroer

CAD Schroer GmbH

Fritz-Peters-Straße 26-30

47447 Moers

Website: www.cad-schroer.com

Email: info@cad-schroer.com

Telephone:

Germany: +49 2841 9184 0

UK: +44 1223 460 408

France: +33 141 94 51 40

Switzerland: +41 44 802 89-80

Italy: +39 02 38303267

USA: +1 866-SCHROER (866-724-7637)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Factory Modelling Prevents Painful Problems here

News-ID: 174972 • Views: …

More Releases from CAD Schroer GmbH

Project engineers explore 3D plant design software at key conferences

At ACHEMA and UK AD & Biogas 2012 CAD Schroer welcomed project engineers, plant providers and Owner/Operators to explore the possibilities offered by large-scale 3D plant design.

Cambridge, UK and Pittsford, NY – 4 October 2012: World Congress or national conference - sustainable energy was top of the agenda at ACHEMA in Frankfurt and UK AD & Biogas in Birmingham, where project engineers had the opportunity to explore flexible,…

Olympic Fever and Pedal Power Drive CAD Anniversary

It’s the 10th anniversary of the MEDUSA 2D/3D drafting software and the MPDS plant design system at CAD Schroer, and the company has been celebrating in the spirit of sports, all for a good cause.

Cambridge, UK and Pittsford, NY – August 2012: Since CAD Schroer acquired MEDUSA and MPDS, its experts have completely overhauled and expanded one of the most flexible engineering software systems on the market. Its…

3D layouts speed up process line design projects

PPMA member webinar for machinery providers highlights the benefits of 3D process line design – from bid-winning pre-sales concepts to fast, high quality project delivery

Cambridge, UK and Pittsford, NY – August 2012: Machinery providers delivering turnkey projects, who need to visualise their equipment in client factories, will learn about the ease and benefits of large-scale 3D process line design during a 45-minute webinar on 15…

Can 3D plant project data control be easy on Administrators?

CAD Schroer‘s new Project Data Control (PDC) environment for MPDS4 ensures that concurrent plant design and global engineering content management doesn’t have to come with a huge implementation burden

Cambridge, UK and Pittsford, NY – July 2012: With the release of its new PDC engineering content management environment, CAD Schroer aims to help process plant and large-scale assembly designers to effectively manage growing engineering design complexity, without…

More Releases for Factory

Shot blasting machine factory

Sino-Abrator is a leading blasting system manufacture which occupies with 13,210 m2 plant in Qingdao, China. Our high reputation stems from comprehensive capabilities covering design, manufacturing, rigorous testing, and after-sales service with strictly comply with CE certification & the ISO:9001 management system.

For decades, this shot blasting machine manufacture specialist has supplied advanced technological solutions for surface finishing. We provide shot blasting, shot peening, and sand blasting…

Factory Direct vs Trading Company Why Sourcing Massage Guns from a Factory

Understanding the Sourcing Landscape for Massage Guns

When diving into the world of massage gun sourcing, it's essential to understand the two main players: factory direct manufacturers [https://www.dariushealth.com/about-us/] and trading companies. Each serves a distinct role in the supply chain, and knowing their differences can save you time, money, and headaches.

Factory Direct vs. Trading Companies

Factory Direct means working straight with the massage gun manufacturer. You get access to custom deep tissue…

Prominent Smart Factory Market Trend for 2025: Advanced Technologies Reshape The …

Which drivers are expected to have the greatest impact on the over the smart factory market's growth?

The escalation in need for industrial robots is anticipated to spur the expansion of the smart factory market. Industrial robots are mechanical devices programmed to autonomously carry out production-related tasks in industrial settings. A smart factory emphasizes on resource optimization and industrial automation, employing instruments like information and smart sensor technologies, robotics, the Internet…

Factory Automation Sensor Market Report 2024 - Factory Automation Sensor Market …

"The Business Research Company recently released a comprehensive report on the Global Factory Automation Sensor Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

According to The Business Research Company's, The factory automation sensor…

Smart Factory Services – Successful conversion to a smart factory

Weinstadt, May 06, 2024 - The system manufacturer KELCH GmbH has developed a modular overall concept to support individual companies in setting up and expanding their smart factory. Our so-called Smart Factory Services are tailored to the needs of machining companies and consist of modules that can be flexibly combined. This offers manufacturing companies the option of only obtaining the solutions that they actually need – whether to improve processes…

Factory Automation Market Future Assessment 2021-2027 : ABB Ltd., Mitsubishi Ele …

Allied Market Research published an exclusive report, titled, “Factory Automation Market by Control and Safety System (Distributed Control System (DCS), Supervisory Control and Data Acquisition System (SCADA), Manufacturing Execution System (MES), Safety Instrumented System (SIS), Programmable Logic Controllers (PLC), and Human Machine Interface (HMI)), Component (Sensor, Controllers, Switches & Relays, Industrial Robots, Drives, and Others), and Industry Vertical (Automotive Manufacturing, Food & Beverage, Oil & Gas Processing, Mining, and Others)…