Press release

Porous aluminum instead of other porous materials

The manufacturing technology of porous aluminum differs from the manufacturing technology of other porous materials. Thanks to the high flexibility and adaptability of the technology, porous aluminum can successfully compete with many porous materials in different applications. In most cases, porous aluminum replaces sintered metals, porous ceramics, porous plastics, nets and wire materials.Porous aluminum instead of a pneumatic silencer / muffler with felt:

Prior to the launch of pneumatic silencers / mufflers made of porous aluminum, multi-piece pneumatic silencers with felt were used. For

each such pneumatic silencer, the thickness of the felt was selected individually and several tests were carried out to obtain the required

parameters of the pneumatic silencer. The use of porous aluminum pneumatic silencers / mufflers made it possible to eliminate a large part of this manual work. The properties of the porous aluminum pneumatic silencers / mufflers

are easily reproducible by appliance of the optimal manufacturing process-dependent parameters.

Porous aluminum instead of sintered pneumatic silencer:

Flat pneumatic silencers made of sinter bronze require installation of 2 plates to achieve the required wall thickness and thus the necessary noise reduction level. Such plates made of sinter bronze are often destroyed by constant

vibration and shock loads as the strength of the sintered bronze is not high enough. Steel cover plates with slots were used to extend the lifetime

of the sintered bronze plates. However, this approach reduced the working surface and thus the efficiency of the pneumatic muffler. Plates of

porous aluminum can easily be manufactured with required thickness. Pneumatic mufflers made of porous aluminium have smaller back

pressure, larger working surface, longer lifetime, are vibration and shock resistant.

Porous aluminum instead of pneumatic sintered silencer with thread:

Standard sintered bronze pneumatic silencers have sufficient noise level reduction, but the shape and size are significantly limited by the sintering technology. Porous aluminum mufflers / silencers can be manufactured in various designs according to your needs and for your individual task. For the manufacturing of porous aluminium products simple conventional moulds will be used, there is no need for cost-intensive pressure-moulds as the sintering technology requires. The innovativeand relatively simple manufacturing technology of porous aluminium allows us to offer you anexcellent price-performance ratio even for small quantities and prototypes.

Porous aluminum instead of porous ceramics:

Ceramic filters must have quite a big wall thickness in order to have a sufficient lifetime. Even with athick wall (which means large weight) such ceramic filters are still fragile and require careful handling.Porous aluminum filters have 5 to 10 times smaller wall thickness, 7 to15 times less weight and at the same time have higher strength, are vibration and impact resistant. With porous aluminium you may apply higher working pressure, which allows better cleaning of the filters in filtration-regeneration cycles, therefore more than doubling of the filters durability compared to ceramic filters.

Porous aluminum instead of porous plastic:

Compared to porous plastics, porous aluminum products have higher strength and higher operating temperature, they require no housing. Porous aluminum filters and pneumatic silencers have a longer durability and can be operated under higher pressure. In addition, porous aluminum is fireproof.

Porous aluminum instead of pressed wire:

Pressed wire filters will be deformed and gradually changing their shape when operated under a high pressure. After the pressure is released, the filter shape is not restored to its original shape. This affects the stability of the filter properties and shortens the durability of the filters. Porous aluminum

filters have a solid and durable shape and stable lifetime properties. Due to the stiffness of porous aluminum, you can obtain shapes and sizes that are not available with pressed wire filters.

EXXENTIS Ltd was founded in 2011. Based in Switzerland near Zurich EXXENTIS operates successfully in Europe as a manufacturer of porous aluminum and works with clients from various industries. Our products made of porous aluminum are produced in our own production facility to the highest quality standards. We offer you individual technical advice for every new task. In an active, ongoing dialogue we find the optimal solution for your requirements. When necessary, our experienced and competent team of engineers develops tailor-made solutions and individual parts. Our core competencies are the development and production of tailor-made, optimal product solutions for complex and unusual tasks in various industrial applications. Our technology makes it possible to produce individual prototypes for testing your ideas - quickly and at attractive prices.

Olga Mühldorfer

Techn. Sales

Exxentis Ltd

Schartenfelsstrasse 6, 5403 Wettingen, Switzerland

Tel.: +41 (0)56 430 03 00

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Porous aluminum instead of other porous materials here

News-ID: 1745411 • Views: …

More Releases from Exxentis Ltd

Have you ever seen such a structure of porous metal?

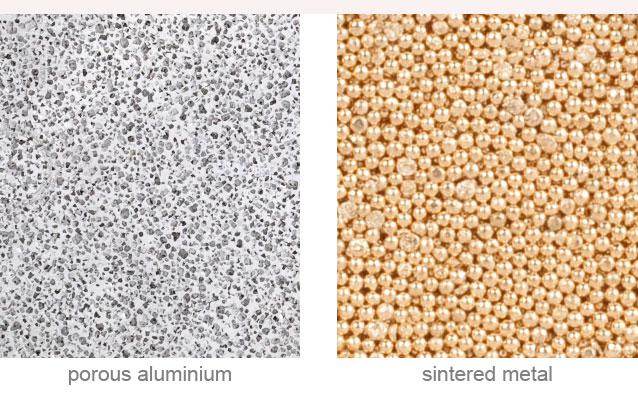

Structure comparison of porous aluminum and sintered metals:

Porous aluminum is produced by casting with salt. This technology offers a unique structure of the porous metal. The structure of porous aluminum and the structure of well known sintered metals are complementary.

The pores in the sintered metal correspond to the metal in the porous aluminum and vice versa. Theoretically, the minimum volume porosity of the sintered metals is 26% and the maximum…

More Releases for Porous

Porous Carbon Market Key Players, Share and Forecast Outlook

"As of 2024, the global porous carbon market is valued at approximately $6.2 billion. The market is anticipated to reach around $9.8 billion by 2034, reflecting a Compound Annual Growth Rate (CAGR) of 4.6% during the forecast period from 2025 to 2034. This growth is driven by increasing demand across various sectors, including energy storage, environmental applications, and advanced materials."

Exactitude Consultancy., Ltd. released a research report titled "Porous Carbon Market".…

Fulfilling Healthcare Needs The Surging Demand For Porous Ceramics In Medical Eq …

Which drivers are expected to have the greatest impact on the over the porous ceramics market's growth?

The growth of the porous ceramic equipment market is being driven by the escalating demand for medical equipment. With reference to devices utilized for various medical needs, medical equipment often incorporates porous ceramics for applications including total hip replacements, dental restorations, and implants, bone fillers, and scaffolds in tissue engineering. The National Health Service,…

What is Porous Graphite? Features and Applications

Porous graphite revolutionizes SiC crystal growth [https://www.semi-cera.com/tac-coating-monocrystal-growth-parts/] by improving yield, reducing defects, and lowering production costs.

Introduction:

Porous graphite [https://www.semi-cera.com/porous-graphite-tube-product/], also known as porous carbon or porous graphite materials, is a specially designed form of graphite featuring interconnected pore networks. This unique material offers superior performance in a range of applications, particularly in the silicon carbide (SiC) crystal growth process. By playing a pivotal role in balancing gas-phase components, isolating trace impurities,…

Porous Silicon Substrates Market Projection By Technology

Report Details:

This report provides in depth study of "Porous Silicon Substrates Market" using SWOT analysis i.e. Strength, Weakness, Opportunities and Threat to the organization. The Porous Silicon Substrates Market report also provides an in-depth survey of key players in the market which is based on the various objectives of an organization such as profiling, the product outline, the quantity of production, required raw material, and the financial health of the…

Porous Soaker Hose System Market Expected To Deliver Dynamic Progression Until 2 …

QY Research has recently published a new report, titled Global Porous Soaker Hose System Market Report, History and Forecast 2017-2028, Breakdown Data by Manufacturers, Key Regions, Types and Application. The report has been put together using primary and secondary research methodologies, which offer an accurate and precise understanding of the Porous Soaker Hose System market. Analysts have used a top-down and bottom-up approach to evaluate the segments and provide a…

Advanced Porous Materials Market Research Report 2018

This report studies the global Advanced Porous Materials market status and forecast, categorizes the global Advanced Porous Materials market size (value & volume) by manufacturers, type, application, and region. This report focuses on the top manufacturers in North America, Europe, Japan, China, and other regions (India, Southeast Asia).

Download FREE Sample of this Report @ https://www.grandresearchstore.com/report-sample/global-advanced-porous-materials-2018-156

The major manufacturers covered in this report

3M

Porex

Mitsui Chemicals

NanoPore Incorporated

Porvair Filtration Group

Porous Materials Inc.

ADMA Products

Geographically, this report…