Press release

Interpack 2011: Easy transport with Montech modular belt conveyors

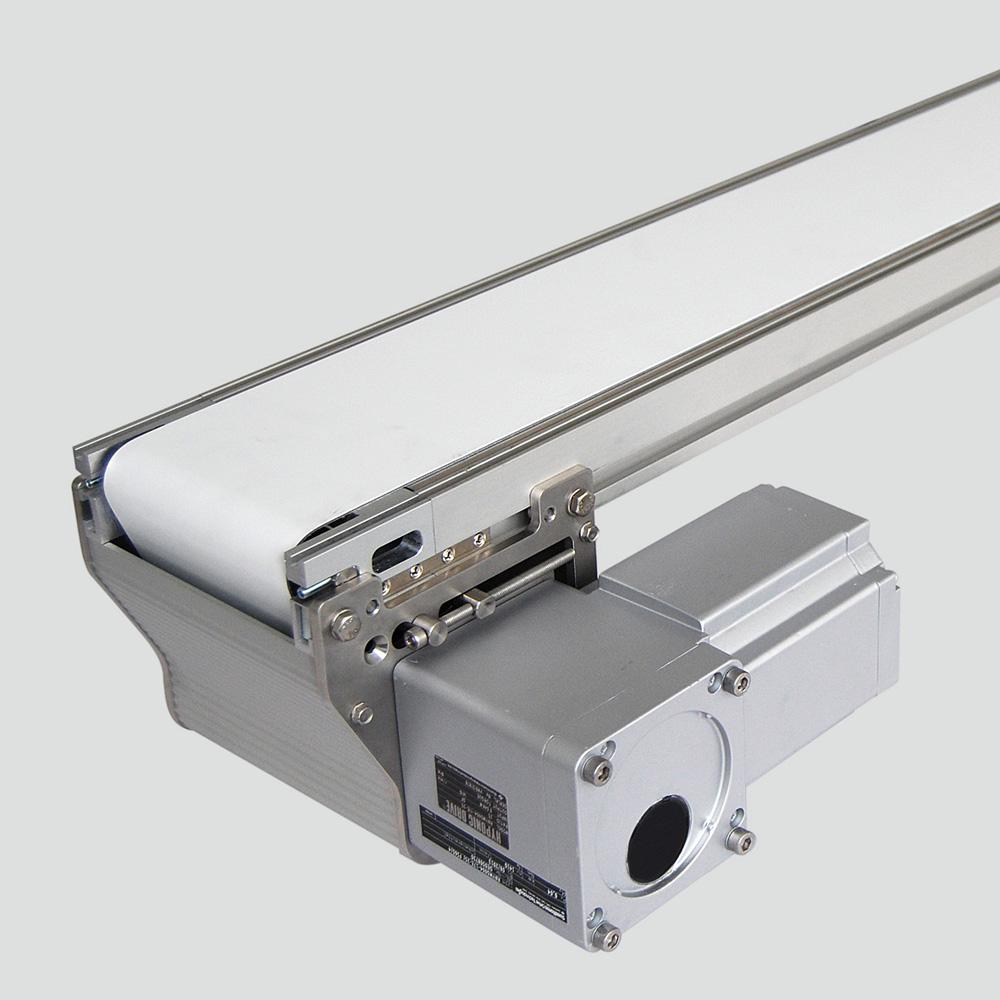

The Swiss belt conveyor specialist Montech AG is exhibiting at interpack 2011, showing specific transport systems and handling components for the packaging industry.At booth B37 in hall 16, visitors will have the opportunity to see the Vacuum belt and the multitrack conveyor in action. The company will also present the entire range of modular belt conveyors.

The Montech conveyors are based on a modular concept with ready-to-use standard components. Thanks to their modularity, the conveyors can be assembled in variable configurations, extended or shortened with a simple and cost-effective approach. In case of subsequent modifications, the belts can thus be adapted to new operating conditions and requirements very easily, avoiding purchasing new belts.

“Modularity allows to adapt the conveyors to the specific requirements of each customer and to incorporate them into complex plants or machinery,” says Gianluca Aloisi, Sales Manager, Montech AG. The Montech belts are particularly suitable for installations on production machinery in different industries and, for instance, find application in packaging equipment, automated assembling systems, machine tools and production plants.

The conveyors have standard widths included between 45 and 800 mm, while their length can be selected freely up to 15 meter length in one millimeter steps. The conveyors can carry weights up to 125 kg.

Multitrack conveyor

To carry parts up to 120 kg, at interpack Montech will show a multitrack conveyor. The belt is available with three different drives with spur gear motor and can be equipped with belts or pulleys. According to the selected drive, there are different options for acceleration, delay, belt speed and positioning. The smooth and delicate handling of parts is guaranteed by accurate acceleration and braking curves.

Vacuum belt conveyor

The Vacuum belt allows conveying all kinds of packages at high speed. Compared to conventional belts, the Vacuum belt offers a more dynamic acceleration and braking curve, combined with higher transport speed. Aloisi: “Conventional handling solutions require an unproductive return track. Montech’s Vacuum conveyor has no return and therefore helps increase productivity in the factory." The conveyor is also more cost effective and, compared to other systems, offers the additional benefit of compact dimensions, according to Aloisi.

Montech AG markets basic modular components for the automation of demanding transport, assembly and production processes. In addition to conventional conveyor belts, the product range includes automation components and the Quick-Set profile system. A specialist in standard and customized transport and conveyor systems, Montech offers an ideal combination of customer-specific solutions with a high degree of standardization. Founded in 1963, the company is based in Switzerland and stands for innovation in the automation industry.

Montech AG

Gewerbestrasse 12

CH-4552 Derendingen

Phone: +41 (0)32 6815500

Fax: +41 (0)32 6821977

E-Mail: info@montech.com

www.montech.com

Presscontact:

Elke Manthei

Phone: +41 (0)32 6815542

E-Mail: elke.manthei@montech.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Interpack 2011: Easy transport with Montech modular belt conveyors here

News-ID: 172708 • Views: …

More Releases from Montech AG

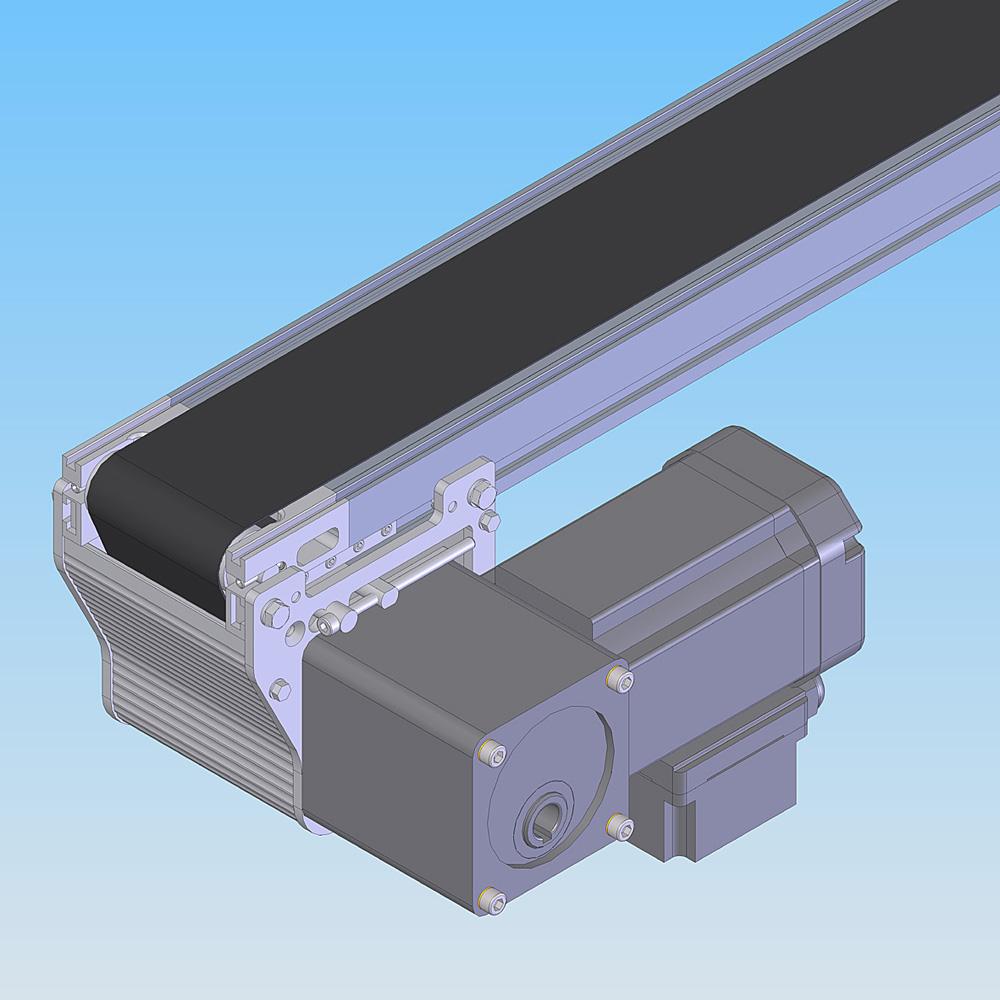

New conveyors from Montech: efficient and user-friendly

The new conveyors TB30 and TB40 from Montech AG are more user-friendly and efficient than the previous models, as a result of their flexibility and drive unit.

Montech’s new TB30 and TB40 conveyors have efficiency-optimized drives and, compared to previous conveyors, are more efficient, offering higher power density with lower energy consumption. With the same chassis width, the belt has a wider useful surface; the belt can be easily and quickly…

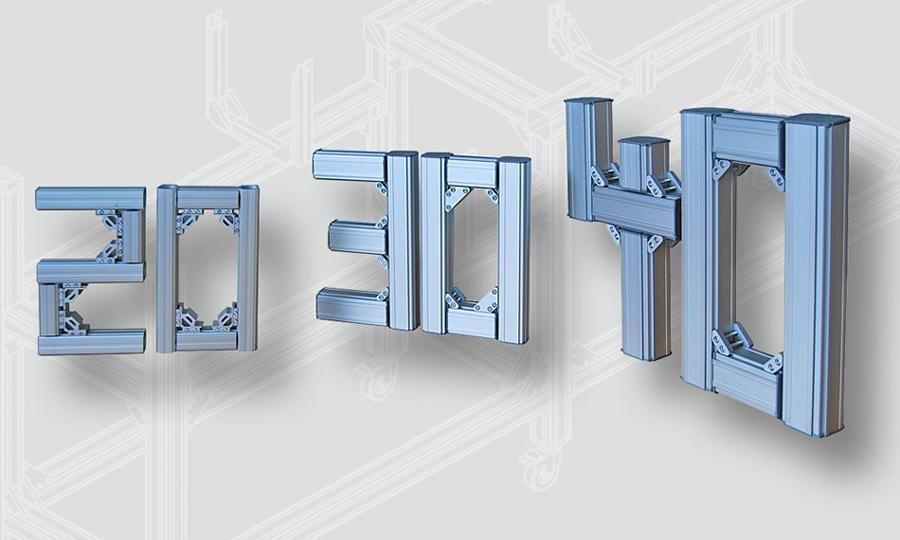

New: Montech Profile System in Size 30

The product range of the Quick-Set Profile System from Montech AG has been expanded with a new size: the Swiss company has implemented sizes 20 and 40 with the new Profile System size 30.

Quick-Set 30 is particularly suitable for substructures of Montech conveyor belts, Quick-Set 40 for precise dimensionally-stable connections like protection devices, and Quick-Set 20 for the quick mounting of structures such as laboratory equipment, factory or office…

Inter airport: industry-specific conveyors from Montech

The Swiss conveyor technology specialist Montech AG is introducing its industry-specific conveyors for check-in and security screening areas at inter airport 2013, in Hall B6, Stand 636.

To weigh and transport baggage at check-in counters, Montech offers a conveyor with incorporated scale, as well as a conveyor for baggage transport. The baggage conveyor is provided with a special surface finishing to prevent scratches and rips. The compact design is ideal for…

Montech: new conveyors and LT40 transport system

At the German tradeshow Motek 2013, the Swiss conveyor technology specialist Montech is presenting new conveyors and the LT40 transport system in Hall 1, Stand 1180.

Montech’s new TB30 and TB40 conveyors have efficiency-optimized drives and, compared to previous conveyors, are more efficient, offering higher power density with lower energy consumption.

The conveyor drive can be moved from the end to the middle of the unit, and vice versa,…

More Releases for Vacuum

Semiconductor Screw Vacuum Pump Market Industry Trends - Atlas Copco (Edwards Va …

MarketQuest.biz proclaims the addition of another new report titled Global Semiconductor Screw Vacuum Pump Market which is a well-synchronized synopsis of the market. The report offers broad insights extracted by thoroughly analyzing historical and current developments in the market. The report outlines the distinguishable players in the global Semiconductor Screw Vacuum Pump market with a clear-cut end goal to give an intelligent standpoint of the forces of the market, while…

Roots Vacuum Pumps Market SWOT Analysis by Key Players: Pfeiffer, Leybold, ANLET …

Roots vacuum pumps, or vacuum boosters, are dry vacuum pumps that are used together with backing pumps in a wide range of applications where large pumping speeds are required. Vacuum boosters operate completely contact-free and without sealing fluids such as oil or water in the working chamber, although with most models the two gearwheels of the synchromesh gearing and the bearings for the impeller shafts are lubricated with oil. Some…

Vacuum Coating Machines Market 2018 Global Key Country Analysis: Denton Vacuum, …

Vendor Landscape

Tetra Technologies, Inc., (U.S.), BP P.L.C. (U.K.), Statoil ASA (Norway), DNV GL (Norway), TechnipFMC PLC (U.K.), AF Gruppen ASA (Norway), Ramboll Group A/S (Denmark), and Aker Solutions ASA (Norway) are some of the key companies operating in the market. Amec Foster Wheeler (U.K.), John Wood Group Plc. (Scotland), Claxton Engineering Services (U.K.), Allseas group SA (Switzerland), and DeepOcean Group (Netherlands) among others.

Market Research Future’s (MRFR) latest study reveals that…

Global Rotary Vane Vacuum Pumps Market- Pfeiffer Vacuum, Tuthill, Osaka Vacuum, …

Global Rotary Vane Vacuum Pumps Market report 2017 is an in-depth research on the current situation of the Rotary Vane Vacuum Pumps industry.

The Scope of the Rotary Vane Vacuum Pumps research report:

The Global Rotary Vane Vacuum Pumps Market primarily includes a basic overview of the Rotary Vane Vacuum Pumps industry. It also includes Rotary Vane Vacuum Pumps definitions, classifications and applications. It segments the market by applications, types, regions, competitive…

Metallurgical High Vacuum Announces High Vacuum Newsletter

Fennville, MI---Metallurgical High Vacuum has created a new “High Vacuum News” to provide heat treat industry professionals with tips and hints to keep their vacuum pumps running strong.

As Geoff Humberstone, MHV President, comments: “This year marks 30 years for us as Metallurgical High Vacuum. Back in 1981, I saw the need for vacuum design and consulting and started the company. Within four years we added pump remanufacturing because we…

Metallurgical High Vacuum Ships Vacuum Chambers (Corrected)

Special Designs are Built to Customer Specifications

Fennville, MI--- Metallurgical High Vacuum recently shipped two chambers for customer-specific applications. One vacuum chamber is over 72” high and will be used in P E. Chemical Vapor Deposition. The other chamber is a 12-inch square design that will be used to weld silicon sticks, complete with a two-stage booster vacuum pumping system. Both chambers are built of type 304 stainless steel for…