Press release

Alloy Wheel Refurbishment Success For The Guyson Wheelmaster

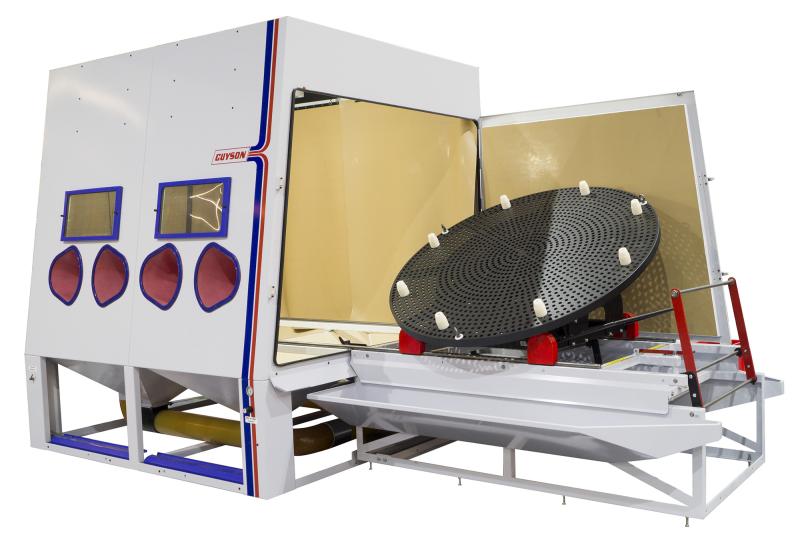

Leading industrial finishing equipment manufacturer Guyson International has seen numerous sales successes with its newly launched Guyson Wheelmaster, to both mobile van operators and static alloy wheel repair shops. This new blast system has been specifically designed for blast etching of alloy wheels and incorporates many application specific handling features that enable the operator to operate this wheel blasting system safely, without heavy lifting.Many encouraging words have been spoken about its improved ergonomic design by all who have attended demonstrations or used it and several large garage franchisers and mobile alloy wheel refurbishment van operators are in the process of evaluating its full potential with Guyson demonstration units out in the field.

One recent successful multiple unit installation has been to Evans Halshaw, a leading volume motor car retailer with numerous sales and service franchises, who took a number of units for both its mobile vans and its garage workshops. David Crowder - Dealer Principal at their Leeds Bodycentre stated that “the Wheelmaster cabinets were performing great, much easier on lifting the wheels about, which makes it easier for the lads and proving a valuable timesaver and in this business time is money”.

The new Guyson Wheelmaster is the ideal machine for mobile alloy wheel repair vans or as a brand new installation into ‘smart’ repair centres or auto body shops looking to offer a value added customer service by bringing the process back in house from subcontractors or indeed as a replacement for old, poorly performing blast units.

The Wheelmaster is fitted with a fully opening front door to allow maximum easy access for loading. Inside the specially designed wheel support cradle tilts and pulls out of the cabinet to allow the wheel to be mounted in a vertical position, removing any likelihood of over-reaching whilst loading wheels. The wheel is located on a central spindle and supported by a cross braced circular support.

The blast cabinet is fitted with extra large armholes to allow maximum operator access whilst blasting and the wheel is rotated by hand so it can be blast etched just as easily by left or right handed operators. A full width foot pedal allows comfortable and responsive action to engage the blast gun and maintain blasting - which ceases the moment that foot pressure is released.

The heavy duty, all steel blast cabinet affords excellent visibility of the wheel and the area being etched, with bright internal lighting delivering even illumination without shadows. Optimum visibility is maintained inside the cabinet by a highly efficient dust collector constantly removing media dust and fine particles.

The blasting process produces an even finish with easy sweeps across the wheel surface and, unlike traditional disc sanders; it allows both easy penetration of the blast media stream between the spokes and also very precise localised etching if required. It also provides a fast and even light etching to remove only the chipped lacquer on virtually new wheels, whilst being capable of etching right back to bare metal if required.

An optional cyclone separator can improve separation of dust from good blast media prior to media being recycled. This means that the consistency of the finish is improved and the cycle times are maintained, as only better quality blast media is recycled. There is also normally an improvement in visibility. Cyclones are available in several options: stand alone, cabinet mounted or as an integral part of an optional pressure fed blast system.

An optional pressure feed blast system is available for intensive blasting or when regularly needing to strip wheels back to bare metal. The pressure feed system offers cycle times that can be up to four times faster than a suction feed system for tougher blasting applications.

Prospective users of Guyson blast systems are encouraged to submit sample components for free feasibility testing to the company’s extensive development workshop located in Skipton, England.

About Guyson

Guyson International Limited is a privately owned family company with a world-wide reputation for excellence in the design and manufacture of blast finishing, spray wash and ultrasonic cleaning equipment. Formed over 70 years ago, the company is registered to BS EN ISO 9001:2008 and its head office is located at Skipton, North Yorkshire, in the north of England. Guyson has four international subsidiary companies: Guyson Corporation of the USA, located in Saratoga Springs, New York State; Guyson SA, situated in Paris, France; Guyson Sdn Bhd in Penang; and Guyson CN, in Wuxi, Jiangsu Province, China.

Guyson International Ltd

Snaygill Industrial Estate

Keighley Road

Skipton, North Yorkshire, BD23 2QR, England

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Alloy Wheel Refurbishment Success For The Guyson Wheelmaster here

News-ID: 163101 • Views: …

More Releases from Guyson International Ltd

Extra-Large Blast Machine for Blast Etching Aerospace Rings

Guyson International, the UK's foremost industrial finishing equipment manufacturer, has installed a Guyson Euroblast® 2-metre PF (Pressure Fed) blast system into a division of a leading European aerospace company. The extra-large blast cabinet is used to deliver a uniform etched key surface on a range of machined circular aluminium rings prior to bonding.

After blast trails performed at the company's Skipton demonstration centre, a Euroblast 2-metre PF blast system (2.1…

Guyson Twin Spindle Blast Machine for Etching Tubular Components

Guyson International, the UK's leading manufacturer of industrial finishing equipment, has recently manufactured and installed into a UK manufacturing company an automated Multiblast RSB twin spindle blast system for externally blast etching various sizes of tubular components. This new blast system incorporates two rotating blast stations with matching top clamps, to hold the product securely, whilst two vertically traversing blast guns produce a uniform blast etch finish over the length…

Guyson Staff Clock-Up 180 Years!

At Guyson International's Skipton headquarters, Monday 15th August saw rain, much needed, and celebrations, much deserved. Employees from the company's blast and wash division gathered outside to congratulate seven employees who were awarded long service awards. And between them amassed a total of 180 years of service at Guyson, with one, Keith Miller celebrating 50 years of service.

In typical unpredictable UK weather, after so many days of bright hot sunshine,…

Guyson Equipment Cleans and Maintains Planing and Woodcutting Tools

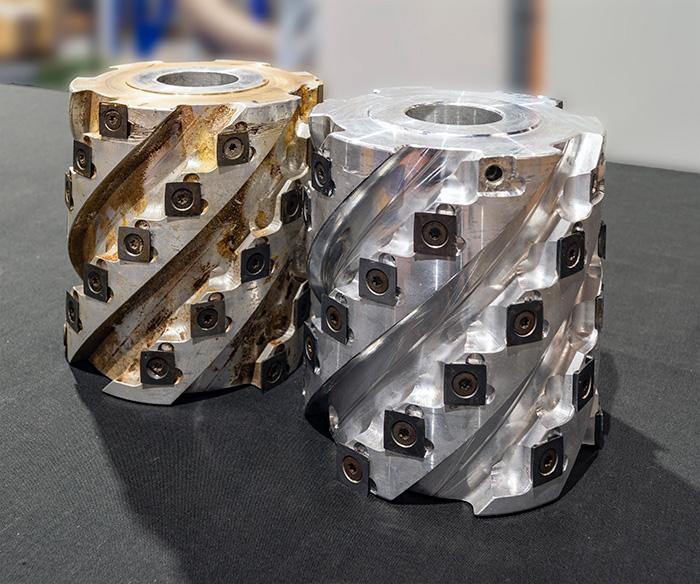

Guyson International, one of the UK's leading manufacturers of industrial finishing equipment, recently delivered a KS450 ultrasonic cleaning tank and a Formula 1200 benchtop bead blast cabinet to RHW (R H Wilson (Lakes) Ltd.) of Kirkby Stephen, a leading timber importer and supplier, for cleaning and maintaining their wood cutting and planing tools.

The problem was how best to clean 'helical planer blocks' to remove a build-up of pitch, sap, resin…

More Releases for Wheelmaster

New Guyson ‘Standard Blast Products’ Brochure

To kick off the New Year, Guyson International, the UK’s leading industrial finishing equipment manufacturer, has just issued a new ‘Standard Blast Products’ brochure that all in one place showcases its comprehensive range of ‘standard’ blast cabinets. This glossy twelve page brochure features their premium ATEX rated blast cabinets, its professional Euroblast® range, light industrial Formula cabinets and specialist alloy wheel refurbishment cabinets.

Potential customers are invited to use the…