Press release

Sheet Molding Compound and Bulk Molding Compound Market by Profiled Key Companies - Citadel Plastics Holding Inc., Polynt S.P.A, Core Molding Technologies Inc., Menzolit GmbH

Sheet Molding Compound and Bulk Molding Compound Market Share, Sheet Molding Compound and Bulk Molding Compound Market Size, Sheet

The demand for sheet molding compound has been on the rise recently due to the growing need for higher mechanical strength applications. Market reports associated with the chemicals and materials sector made accessible by Market Research Future along with published reports on other sectors have been lately put out along with a report on this industry. The market is likely to achieve revenues worth USD 3,531.1 Million while growing at a CAGR of 6.5% approximately in the forecast period.

Receive A Sample Report @ https://www.marketresearchfuture.com/sample_request/1671

Top 10 Key Players:

Citadel Plastics Holding Inc.

IDI Composite International

Polynt S.P.A

Menzolit GmbH

Core Molding Technologies Inc.

Changzhou Runxia Fiberglass Products Co., Ltd.

Continental Structural Plastics Inc.

Showa Denko K.K.

Royal Tencate

Industry Segments:

The segmentation of the sheet molding compound and bulk molding compound market is carried out on the basis of type, application, and region. On the basis of type, the market segmentation includes carbon fiber and glass fiber. On the basis of application, the market is segmented into electrical, transportation, and construction. Additionally, on the basis of region, the market is segmented as APAC, North America, Europe, and Rest of the World.

To Browse Complete Market Information, Click Here @ https://www.marketresearchfuture.com/reports/sheet-molding-compound-market-1671

List Of Table:

Table 1 Global: Market Size And Growth Rate, 2011-2016, (Usd Million)

Table 2 Global: Market Size And Growth Rate, 2011-2016, (Million Tons)

Table 3 Global: Sheet Molding Compound And Bulk Molding Compound, By Type, 2011-2016, (Usd Million)

Table 4 Global: Sheet Molding Compound And Bulk Molding Compound, By Type, 2011-2016, (Million Tons)

Table 5 Global: Sheet Molding Compound And Bulk Molding Compound, By Application, 2011-2016, (Usd Million)

Table 6 Global: Sheet Molding Compound And Bulk Molding Compound, By Application, 2011-2016, (Million Tons)

Table 7 Global Price, By Region (2011-2016), (Usd/Ton)

continued..

To Avail Discount along with TOC, Click @ https://www.marketresearchfuture.com/check-discount/1671

Geographical Summary:

The regional analysis of the market perceives that the APAC region will increase at a CAGR of 7.2% over the forecast period with a market size of USD 1,885.2 million by 2021. The market share of the region is attributed to the rising transportation and electrical & electronics industries in this region. China stands on the highest position as the producers and consumer segment which accounts for a total of 50% approximately of the global market. However, the European region is anticipated to obtain a market share of USD 923.7 million and will increase at a CAGR 4.9% by 2021.

Market Synopsis:

The demand for sheet molding compound has been on the rise recently due to the growing need for higher mechanical strength applications. Market reports associated with the chemicals and materials sector made accessible by Market Research Future along with published reports on other sectors have been lately put out along with a report on this industry. The market is likely to achieve revenues worth USD 3,531.1 Million while growing at a CAGR of 6.5% approximately in the forecast period.

Receive A Sample Report @ https://www.marketresearchfuture.com/sample_request/1671

Top 10 Key Players:

Citadel Plastics Holding Inc.

IDI Composite International

Polynt S.P.A

Menzolit GmbH

Core Molding Technologies Inc.

Changzhou Runxia Fiberglass Products Co., Ltd.

Continental Structural Plastics Inc.

Showa Denko K.K.

Royal Tencate

Industry Segments:

The segmentation of the sheet molding compound and bulk molding compound market is carried out on the basis of type, application, and region. On the basis of type, the market segmentation includes carbon fiber and glass fiber. On the basis of application, the market is segmented into electrical, transportation, and construction. Additionally, on the basis of region, the market is segmented as APAC, North America, Europe, and Rest of the World.

To Browse Complete Market Information, Click Here @ https://www.marketresearchfuture.com/reports/sheet-molding-compound-market-1671

List Of Table:

Table 1 Global: Market Size And Growth Rate, 2011-2016, (Usd Million)

Table 2 Global: Market Size And Growth Rate, 2011-2016, (Million Tons)

Table 3 Global: Sheet Molding Compound And Bulk Molding Compound, By Type, 2011-2016, (Usd Million)

Table 4 Global: Sheet Molding Compound And Bulk Molding Compound, By Type, 2011-2016, (Million Tons)

Table 5 Global: Sheet Molding Compound And Bulk Molding Compound, By Application, 2011-2016, (Usd Million)

Table 6 Global: Sheet Molding Compound And Bulk Molding Compound, By Application, 2011-2016, (Million Tons)

Table 7 Global Price, By Region (2011-2016), (Usd/Ton)

continued..

To Avail Discount along with TOC, Click @ https://www.marketresearchfuture.com/check-discount/1671

Geographical Summary:

The regional analysis of the market perceives that the APAC region will increase at a CAGR of 7.2% over the forecast period with a market size of USD 1,885.2 million by 2021. The market share of the region is attributed to the rising transportation and electrical & electronics industries in this region. China stands on the highest position as the producers and consumer segment which accounts for a total of 50% approximately of the global market. However, the European region is anticipated to obtain a market share of USD 923.7 million and will increase at a CAGR 4.9% by 2021.

Contact:

Market Research Future

Office No. 528, Amanora Chambers

Magarpatta Road, Hadapsar,

Pune - 411028

Maharashtra, India

+1 646 845 9312

Email: sales@marketresearchfuture.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Sheet Molding Compound and Bulk Molding Compound Market by Profiled Key Companies - Citadel Plastics Holding Inc., Polynt S.P.A, Core Molding Technologies Inc., Menzolit GmbH here

News-ID: 1579605 • Views: …

More Releases from Market Research Future (MRFR)

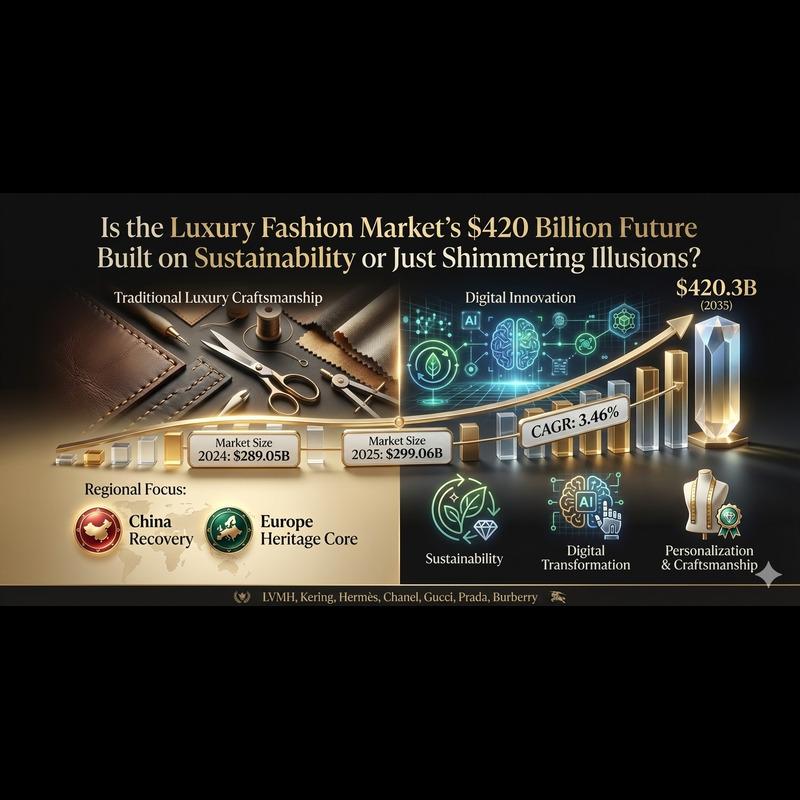

Japan Luxury Fashion Market Outlook 2035: How Heritage, Innovation, and a 3.42% …

The Japan Luxury Fashion Market stands as one of the most sophisticated and resilient segments within the global luxury industry. Rooted in deep cultural appreciation for craftsmanship, quality, and brand heritage, Japan has long been a priority market for leading luxury fashion houses. Valued at USD 10.84 billion in 2024, the market is projected to reach USD 11.21 billion in 2025 and further expand to USD 15.68 billion by 2035,…

Cutting Boards Market Outlook 2035: Eco-Friendly Innovation Drives a 5.16% CAGR …

The global Cutting Boards Market is experiencing steady and resilient growth as consumer kitchens evolve toward safer, more sustainable, and design-oriented food preparation tools. Cutting boards, once considered a basic kitchen accessory, are now influenced by material innovation, hygiene standards, and lifestyle shifts such as home cooking and premium kitchenware adoption. In 2024, the market was valued at USD 1.756 billion and is expected to grow to USD 1.847 billion…

Capsule Hotel Market Surges at 6.22% CAGR: How Smart, Affordable Stays Will Driv …

The Capsule Hotel Market is emerging as one of the most disruptive segments within the global hospitality industry, driven by rising urbanization, changing travel behavior, and a growing preference for affordable yet functional accommodation. Originating in Japan as a solution for space constraints and budget-conscious travelers, capsule hotels have evolved into a globally recognized lodging format blending efficiency, privacy, and modern design. In 2024, the market was valued at USD…

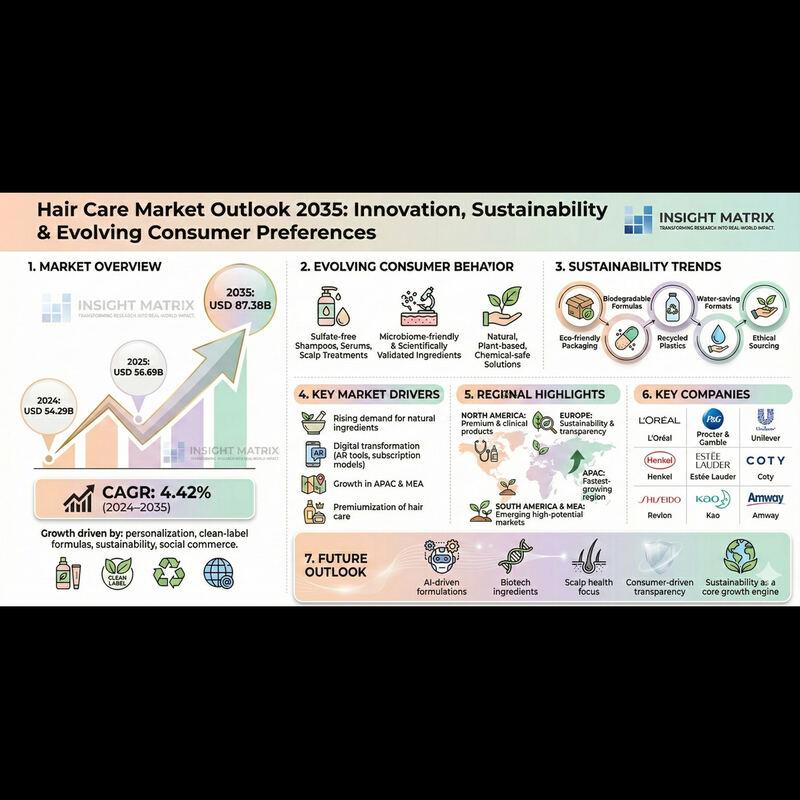

India Hair Care Market Outlook 2035: Natural Ingredient Shift Accelerates Growth …

The India Hair Care Market is witnessing steady and resilient expansion, driven by evolving consumer lifestyles, increasing awareness of personal grooming, and a strong cultural emphasis on hair health. In 2024, the market size stood at USD 4,100.0 million and is projected to grow to USD 4,287.37 million in 2025, eventually reaching USD 6,700.0 million by 2035, registering a CAGR of 4.57% during the forecast period (2025-2035). India's diverse demographics,…

More Releases for Molding

Differences Between Flaskless Molding Machines and Flask Molding Machines

Flaskless molding machines [https://www.junengmachinery.com/servo-molding-machine-products/] and flask molding machines are two primary types of equipment used in foundry production for making sand molds (castings molds). Their core distinction lies in whether they use a flask to contain and support the molding sand. This fundamental difference leads to significant variations in their processes, efficiency, cost, and applications.

Key Differences

Core Concept:

Flask Molding Machine: Requires the use of a flask during mold making. A flask…

LSR Molding: Understanding Silicone Rubber Injection Molding

Liquid Silicone Rubber (LSR) molding is a specialized manufacturing process used to create flexible, durable, and heat-resistant silicone parts. This technique is widely used across industries such as automotive, medical, electronics, and consumer goods. Its ability to produce high-quality parts with precision and consistency makes it a top choice for many manufacturers.

• What Is LSR Molding?

LSR molding, or Liquid Silicone Rubber injection molding (https://www.newtopcustomsilicone.com/capabilities/liquid-silicone-injection-molding/), involves injecting two-component platinum-cured silicone into…

HDPE Blow Molding and Injection Molding Containers Market

Persistence Market Research (PMR) has published a new research report on HDPE blow molding and injection molding containers. The report has been titled "HDPE Blow Molding and Injection Molding Containers Market: Global Industry Analysis 2013-2017 and Forecast 2018-2026." The proliferating demand for HDPE blow molding and injection molding containers is largely from the beverage, chemical & petrochemicals, and pharmaceuticals industries, owing to the barrier properties of HDPE and convenience in…

Sheet Molding Compound and Bulk Molding Compound Market - Growth Prophesy 2025 | …

Global Sheet Molding Compound and Bulk Molding Compound Market: Snapshot

The global market for sheet molding compound and bulk molding compound is expected to advance with the launch of superior quality, lightweight, and more durable bulk molding and sheet molding compounds. By virtue of their higher line throughputs and lower production costs, these compounds are increasingly preferred by several leading manufacturers. As an augmenting number of advanced automobiles and luxury brands…

HDPE Blow Molding and Injection Molding Containers Market 2026

Due to its intrinsic physical and mechanical properties, high density polyethylene (HDPE) is highly used as packaging materials in different industries including food, beverages, pharmaceuticals, cosmetics, homecare, chemicals, and petrochemicals. Urbanization, changing consumer preferences, and expanding middle class have significantly contributed to the rising demand for consumer goods. Increased demand for consumer goods has, in turn, revolutionized the packaging industry, especially plastic packaging.

Polyethylene is most commonly used in the packaging…

Sheet Molding Compound and Bulk Molding Compound Market 2017-2025 : Polynt S.P.A …

Global Sheet Molding Compound and Bulk Molding Compound Market: Snapshot

The global market for sheet molding compound and bulk molding compound is expected to advance with the launch of superior quality, lightweight, and more durable bulk molding and sheet molding compounds. By virtue of their higher line throughputs and lower production costs, these compounds are increasingly preferred by several leading manufacturers. As an augmenting number of advanced automobiles and luxury brands…