Press release

Pneumatic Rollers Volume Analysis, Segments, Value Share and Key Trends 2018-2020

DefinitionPneumatic rollers are comprised of set of tires at the front and the rear end. Pneumatic rollers are able to exert high contact pressures ranging from 500 Kpa to 700 Kpa and are used widely in the construction of roadways, and highways. Pneumatic rollers are also used for non-cohesive and fine grained soils. They are a much preferred compaction solution for road pacing projects.

Segmentation

The market for pneumatic rollers has been segmented in detail for providing a holistic understanding to the reader. The pneumatic rollers market is segmented on the basis of engine capacity, operating capacity, drum width and region. Pneumatic rollers in the engine capacity are further classified into up to 100 HP, 100-130 HP and more than 130 HP variants. The operating capacity segment includes pneumatic rollers with up to 8000 Kg, 8,000-12,000 Kg, 12,000 to 18,000 Kg and more than 18,000 Kg. Pneumatic rollers in the drum width segment are categorized into up to 1,800 mm, 1,800-2,000 mm, 2,000-2,200 mm and more than 2,200 mm. Key regions such as North America, Latin America, Europe, CIS & Russia, Japan, Asia Pacific excluding Japan (APEJ) and Middle East and Africa (MEA) are covered in the report.

Request Sample Report @ https://www.factmr.com/connectus/sample?flag=S&rep_id=1913

Research Methodology

Data and statistics on pneumatic rollers market provided in the report are gleaned using a unique research methodology. Primary and secondary research methods are used to garner data along with information from external sources. All data points gathered are triangulated to obtain high statistics and insights with high precision and accuracy, increasing the credibility of pneumatic rollers market report.

Key Findings

Hydrostatic Wheel Drive Concept Proliferating in the Pneumatic Roller Space

Hydrostatic transmission (HST) or hydrostatic wheel drive is largely preferred in compaction equipment such as pneumatic rollers over gear transmission as HST offers rapid alterations in speed ratio. There is a likelihood of efficiency being compromised with using hydrostatic wheel drive, however, it is offset with enhance maneuverability allowing the pneumatic rollers to operate over a wide range of speed/torque ratios. Various manufacturers have recently been integrating hydrostatic wheel drive in their pneumatic rollers, to name a few:

BOMAG has introduced new soil pneumatic rollers with hydrostatic four-wheel drive. This variant includes sealed frame design. The new BC462EB pneumatic roller have been introduced in the North America market

Volvo Construction Equipment Corporation has introduced PT220 pneumatic roller with hydrostatic drive that offer smooth operation. It includes double drum vibratory compactors that enable perfect mat with appropriate pressure. With hydrostatic drive in PT220 pneumatic rollers, efficient transition between reverse and forward direction is possible without damaging the mat

Case Construction has come up with SV series pneumatic rollers that use three hydrostatic drives to impart motion to the drum and rear wheels. This axle-free design has facilitated minimization of hood height enhancing visibility and efficiency

Request/View Toc@ https://www.factmr.com/connectus/sample?flag=T&rep_id=1913

Competitive Landscape

The report on pneumatic rollers has profiled key companies such as Volvo Construction Equipment, Caterpillar Inc., Dynapac AB, Hamm AG and Bomag GmbH. Key facets of these players including product developments and innovation along with market shares are covered in this chapter.

Manufacturers of pneumatic rollers are focusing on design developments in a bid to enhance productivity, efficiency, reducing carbon emissions and improving overall performance. For instance, Hitachi Construction Machinery Co. Ltd., has introduced ZC220P-6 pneumatic roller that meet standards of “Off-Road Act” and facilitate eco-friendly performance, ease in maintenance using DOC (Diesel Oxidation Catalyst) and safety.

Hamm AG has introduced GRW 280i pneumatic roller with easy drive that facilitates simplified operation and flexibility. This intelligent drive also enables automatic sift raps to obtain even and gentle braking in turn preventing uneven compaction.

Manufacturers of pneumatic rollers are also focusing on introducing pneumatic rollers with new combination rollers. Volvo has introduced CR30B and CR 35B combination pneumatic rollers with for small scale compaction projects that enable high quality and dense mat owing to the unique combination of two methods of compaction.

Speak To Research Analyst for Detailed Insights @ https://www.factmr.com/connectus/sample?flag=AE&rep_id=1913

Security Marking for Pneumatic Rollers Becoming Essential – Adoption of CESAR Witnessed

Manufacturers of pneumatic rollers are intensifying their security measures on the back of increasing theft rates of pneumatic rollers. Various leaders in compaction technology have steeped-up their security markings on their range of pneumatic rollers in response to consistency in theft rates since the past couple of years. Construction Equipment Security and Registration (CESAR) has become a viable option for manufacturers of pneumatic rollers since 2008 till date. Though equipment theft has been reduced by over 60% since 2007, however, CEA predicts that theft cannot be completely eliminated. This remains a key challenge for manufacturers and CESAR can act as a theft deterrent. According to Construction Equipment Association (CEA), it is advisable for manufacturers of pneumatic rollers to implement CESAR to avoid further theft possibilities.

Road Construction of More Than 25 Million Kilometers by 2050 to Trigger Demand for Pneumatic Rollers

Transportation infrastructure plays a vital role in managing export and imports of goods across various industries, in turn contributing to the economic development of countries. In developing economies infrastructure projects are increasing at a substantial rate, particularly construction of roads, railways, and dams. Pneumatic rollers are extensively being used in road construction projects as they provide improved static penetration relocating the particles in turn enhancing the density after asphalt application. According to Global Road Map – an alliance of environmentalists, scientists, geographers and agricultural specialist – by end of 2050, new road construction of more than 25 million kilometers is anticipated. This is likely to drive the demand for pneumatic rollers in the forthcoming years.

Access This Report @ https://www.factmr.com/checkout/1913/S

Rental Business –Trend Complementing Sales of Pneumatic Rollers

Small and medium size contractors are more inclined toward using rented construction equipment such as pneumatic rollers owing to their high initial cost. Using rented pneumatic rollers on project basis can facilitate significant cost reductions of construction projects, in turn enhancing profitability. Dealers of pneumatic rollers can lease out pneumatic rollers as well as provide customization options based on project requirements along with technical assistance. Moreover, dealers in compaction equipment rental space can provide contractors with advanced pneumatic rollers at reasonable pricing. This can support contractors as they can spend extra capital on other tasks such as additional skilled labor, thus complementing business expansion. This has resulted in a significant increase in dealers of pneumatic rollers purchasing the equipment from OEMs and carrying out leasing activities.

Operator Safety Remains a Highly Emphasized Area

Safety of personnel operating pneumatic rollers has gained significant importance on the back of increasing accidents and fatalities associate with compaction equipment. According to NIOSH (National Institute for Occupational Safety and Health) it is imperative for manufacturers of pneumatic rollers to ensure operator safety by providing sufficient training, integrating pneumatic rollers with ROPS (Roll-Over Protective Structures) and seat belts in pneumatic rollers. Against this backdrop, companies are introducing pneumatic rollers with advanced safety for operators, which is likely to influence the growth of the pneumatic rollers market in the coming years. For instance, Caterpillar Inc., a new pneumatic roller with operator that seat that can rotate 360 degrees can ensure higher operator safety. This facilitates enhanced operator visibility eliminating the pneumatic rollers to reverse on field.

Energy Efficient Pneumatic Rollers – An Upcoming Trend

Construction equipment companies worldwide are largely focusing on sustainable development of projects by acquiring certifications with respect to energy efficiency. With growing concerns of environmental pollution, manufacturers of pneumatic rollers are required to develop designs that feature reduced emissions and carbon footprint during the entire project cycle. Moreover, manufacturers of pneumatic rollers are optimizing pneumatic rollers’ pump setting that can facilitate a significant reduction in fuel consumption, in turn decreasing carbon emissions.

About FactMR

FactMR is a fast-growing market research firm that offers the most comprehensive suite of syndicated and customized market research reports. We believe transformative intelligence can educate and inspire businesses to make smarter decisions. We know the limitations of the one-size-fits-all approach; that's why we publish multi-industry global, regional, and country-specific research reports.

Contact Us

FactMR

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Email: sales@factmr.com

Web: www.factmr.com/

Follow Us on Linkedin: www.linkedin.com/company/factmr/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Pneumatic Rollers Volume Analysis, Segments, Value Share and Key Trends 2018-2020 here

News-ID: 1553942 • Views: …

More Releases from Fact.MR

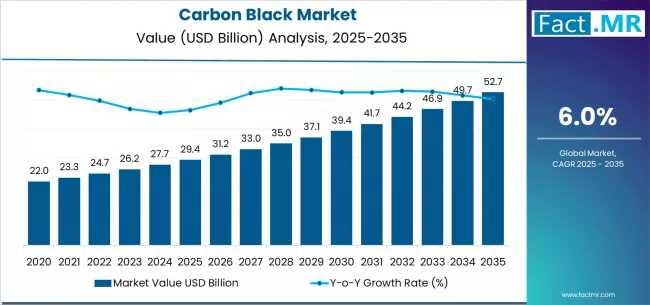

Carbon Black Market Forecast 2026-2036: Market to Reach USD 52.7 Billion by 2036 …

The global carbon black market is valued at USD 29.4 billion in 2025 and is projected to reach USD 52.7 billion by 2035. This robust expansion represents a total growth of 79.1%, progressing at a compound annual growth rate (CAGR) of 6.0% over the ten-year forecast period. As automotive manufacturing scales and tire production capacities rise, the market is expected to grow by approximately 1.8X, driven by the essential role…

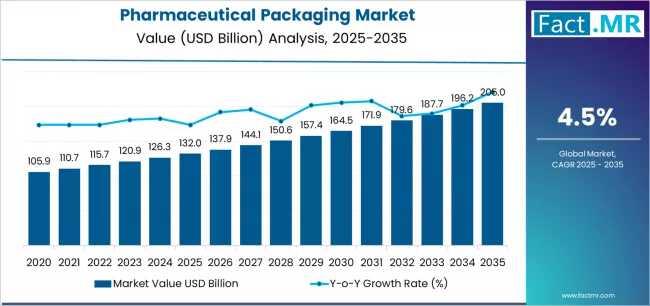

Pharmaceutical Packaging Market Forecast 2026-2036: Market to Reach USD 206.0 Bi …

The global pharmaceutical packaging market is valued at USD 132.0 billion in 2026 and is projected to reach USD 206.0 billion by 2036, expanding at a steady CAGR of 4.5%. This growth reflects a fundamental shift toward advanced sterile packaging, driven by the rapid rise of biologics and the necessity for global regulatory harmonization.

Get Access of Report Sample: https://www.factmr.com/connectus/sample?flag=S&rep_id=4573

pharmaceutical packaging market Quickstat

Market Size 2026: USD 132.0 billion

Market Size…

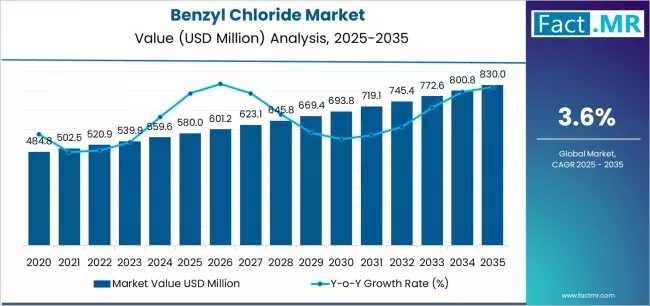

benzyl chloride Market Forecast 2026-2036: Market to Reach USD 830.0 Million by …

The global benzyl chloride market is projected to expand from a valuation of USD 580.0 million in 2025 to approximately USD 830.0 million by 2035. This growth represents an absolute increase of USD 250.0 million, with the market forecast to grow at a compound annual growth rate (CAGR) of 3.6% over the ten-year period. As a critical chemical intermediate, benzyl chloride is seeing heightened utilization in pharmaceutical manufacturing and the…

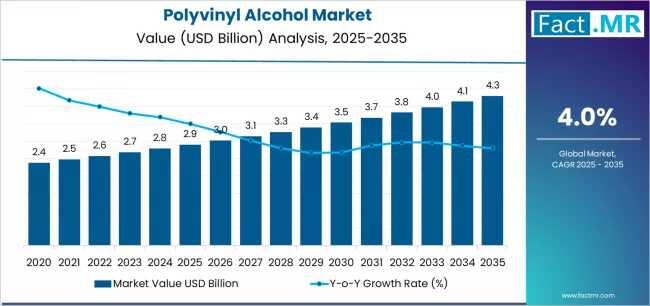

Polyvinyl Alcohol Market Forecast 2026-2036: Market to Reach USD 4,300.0 Million …

The global Polyvinyl Alcohol Market is valued at USD 2,900.0 million in 2025 and is projected to reach USD 4,300.0 million by 2035. This steady expansion represents a CAGR of 4.0% over the ten-year assessment period, marking an absolute increase of USD 1,400.0 million. The market's growth is primarily underpinned by an escalating global demand for water-soluble packaging solutions and advanced film-forming technologies across industrial, textile, and food sectors.

Get Access…

More Releases for Pneumatic

Pneumatic And Semi-Pneumatic Wheels Market Size by Type, Application, and Region …

USA, New Jersey- According to Market Research Intellect, the global Pneumatic And Semi-Pneumatic Wheels market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

Because they are used so extensively in sectors including automotive, material handling, construction, and agriculture, the pneumatic and semi-pneumatic wheel markets are seeing…

Pneumatic Chisel Hammers Market Size, Share and Forecast By Key Players-Bosch, N …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- According to the MRI Team's Market Research Intellect, the global Pneumatic Chisel Hammers market is anticipated to grow at a compound annual growth rate (CAGR) of 7.77% between 2024 and 2031. The market is expected to grow to USD 23.07 Billion by 2024. The valuation is expected to reach USD 38.95 Billion by 2031.

Because pneumatic chisel hammers are so widely used in the metalworking, automotive, and construction industries, the market for…

Pneumatic Conveying System

Altomech is a renowned company that specializes in the design and manufacturing of advanced pneumatic conveying systems. Pneumatic conveying systems are vital in various industries for the efficient and dust-free transfer of bulk materials like powders, granules, and other particulate matter. Altomech has gained recognition for its innovative solutions and cutting-edge technology, making it a trusted partner for industries ranging from food and pharmaceuticals to chemicals and plastics.

Key Features and…

Pneumatic Comfort Takes the Wheel : Unveiling the Automotive Pneumatic Comfort S …

According to a recent report published by Allied Market Research, titled, "Automotive Pneumatic Comfort Seat System Market by Vehicle Type, Propulsion Type, and Function: Global Opportunity Analysis and Industry Forecast, 2020-2030," The global automotive pneumatic comfort seat system market was valued at $1.11 billion in 2020, and is projected to reach $2.03 billion by 2030, registering a CAGR of 6.5%.

North America dominates the market in terms of revenue, followed by…

Pneumatic Tourniquet

The global Pneumatic Tourniquet market is estimated to attain a valuation of US$ 1 Bn by the end of 2032, states a study by Transparency Market Research (TMR). Besides, the report notes that the market is prognosticated to expand at a CAGR of 8% during the forecast period, 2022-2032.

The key objective of the TMR report is to offer a complete assessment of the global market including major leading stakeholders of…

Fact.MR Pneumatic Equipment Market Segmented By Product Type - pneumatic valves, …

Expanding Horizons in Healthcare and Food Sectors

Pneumatic equipment market has been gaining significant traction because of its utilization in nearly every field and broad application in the end-user industries. The use of pressurized gas for motion is called pneumatics, and upon compressing atmospheric air, there are equipment that can efficiently maintain a sustainable supply. The equipment that carry out such mechanisms to obtain movement are pneumatic equipment. Various pneumatic equipment…