Press release

Hydropower Lubricants Market: Market Intelligence and Market Trends

Introduction:Lubricants, in general, are used to reduce friction between the moving parts of a machine and prevent its wear, thereby increasing the equipment life. A lubricant may also be used to dissipate heat, prevent rust and corrosion, flushing contaminants away and acting as a barrier towards impurities. In hydropower installations, heavy machinery is used and the lubricants required are termed as, hydropower lubricants. Hydropower lubricants are used in water turbines, generators, gears, chains and other hydraulic steel structures, to name a few. Hydropower lubricants should function with paramount reliability even under adverse weather conditions. Hydropower lubricants must be resistant to ageing and oxidation. In other words, hydropower lubricants must have a long life with low maintenance.

Along with being used for diverse applications, hydropower lubricants must comply with the stringent environmental laws of several governments. Hydropower lubricants used for turbines must be resistant to emulsification and should readily separate from water. Hydrolytic stability is a prominent factor in selection of a hydropower lubricant due to continuous presence of water.

A sample of this report is available upon request @ https://www.futuremarketinsights.com/reports/sample/rep-gb-7211

Market Dynamics:

With the exploitation of hydro-electricity on a much larger scale than ever before, need for better quality product will keep on rising. In a niche market like this, innovation always plays a vital role in driving the market. Heavy hydropower lubricants, as compared to light hydropower lubricants, are expected to grow in demand. Maintenance of hydropower equipment drives this market.

Energy demand is gradually increasing worldwide. Along with the construction of new hydropower plants, efforts are being made to increase the capacity and efficiency of existing hydropower plants. This will result in a steady growth of the hydropower lubricants. With “Affordable and Clean Energy” being one of the 17 sustainable goals of United Nations which aims towards supplying green and cheap electricity to all by 2030, hydropower will play a vital role in achieving it. Hence, boosting the hydropower lubricants market.

The cost of hydropower lubricants, especially biodegradable hydropower lubricants, is comparatively higher than other mineral based oils. However, accidental discharge of biodegradable hydropower lubricants into the water body would result in far less consequential loss when compared to a mineral or synthetic lubricant discharge. Also, a switch from traditional mineral based oils to biodegradable hydropower lubricants would cost much lower than changing the complete system. Still, the fact cannot be overlooked that any contact between biodegradable hydropower lubricants and water will accelerate the rate of oxidation of the hydropower lubricants. This would result in a frequent replacement of the biodegradable hydropower lubricants.

Out of all mineral oils, paraffinic oils are widely used due to the greater resistance to oxidation, higher viscosity index and lower volatility. Synthetic hydropower lubricants are superior to mineral hydropower lubricants in almost all circumstances. However, the application of synthetic hydropower lubricants is limited due its higher cost.

Market Segmentation:

Hydropower lubricants market can be segmented on the basis of base oil, degradability, performance and equipment specific applications.

On the basis of base oil, hydropower lubricants can be segmented by:

Mineral oil

Synthetic oil

On the basis of degradability, hydropower lubricants can be segmented into:

Biodegradable

Non-biodegradable

On the basis of performance, hydropower lubricants can be segmented as:

Heavy duty lubricants

Light duty lubricants

On the basis of equipment specific applications, hydropower lubricants can be classified into:

Hydraulic fluids

Lubricants for generator bearings

Gear oils

Turbine oils

Wire ropes lubricants

Lubricating greases

Others

Regional Outlook:

Out of all the renewable energy generated worldwide, hydropower comprises of around 70% of the electricity generated. Regions like Asia Pacific, North America followed by Europe are leading in electricity generation from hydropower plants due to large number of rivers and advanced technology used. These regions will be a key market to look out for the hydropower lubricants.

Investments in renewable energy generation in countries like China, Brazil and India, these regions will eventually grow to be a prominent market for hydropower lubricants.

To view TOC of this report is available upon request @ https://www.futuremarketinsights.com/toc/rep-gb-7211

List of Market Participants:

Exxon Mobil Corporation

PANOLIN AG

Royal Dutch Shell plc

Total S.A.

Lubrication Engineers, Inc.

Chevron Corporation

Brewer-Hendley Oil Company

JXTG Nippon Oil & Energy Corporation

FUCHS Petrolub SE

ENGEN PETROLEUM LTD

Paras Lubricants Ltd.

Matrix Specialty Lubricants B.V.

Perto-Canada Lubricants Inc.

About Us

Future Market Insights is the premier provider of market intelligence and consulting services, serving clients in over 150 countries. FMI is headquartered in London, the global financial capital, and has delivery centres in the U.S. and India.

FMI’s research and consulting services help businesses around the globe navigate the challenges in a rapidly evolving marketplace with confidence and clarity. Our customised and syndicated market research reports deliver actionable insights that drive sustainable growth. We continuously track emerging trends and events in a broad range of end industries to ensure our clients prepare for the evolving needs of their consumers.

Contact Us

U.S. Office

616 Corporate Way, Suite 2-9018,

Valley Cottage, NY 10989,

United States

T: +1-347-918-3531

F: +1-845-579-5705

Email: sales@futuremarketinsights.com

Web: https://www.futuremarketinsights.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Hydropower Lubricants Market: Market Intelligence and Market Trends here

News-ID: 1505623 • Views: …

More Releases from Future Market Insights

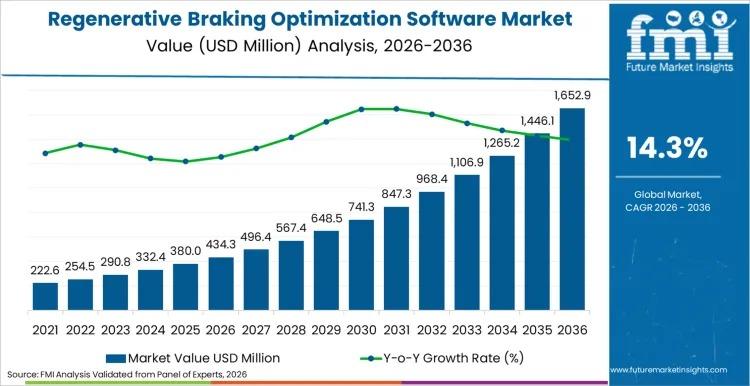

Global Regenerative Braking Optimization Software Market to Reach USD 1,652.9 Mi …

The global regenerative braking optimization software market is entering a phase of accelerated expansion, driven by rapid electrification of vehicle platforms and the automotive industry's transition toward software-defined control systems. Spending on regenerative braking optimization software is projected to increase from USD 434.3 million in 2026 to USD 1,652.9 million by 2036, reflecting a strong compound annual growth rate (CAGR) of 14.3%. This growth underscores the rising strategic importance of…

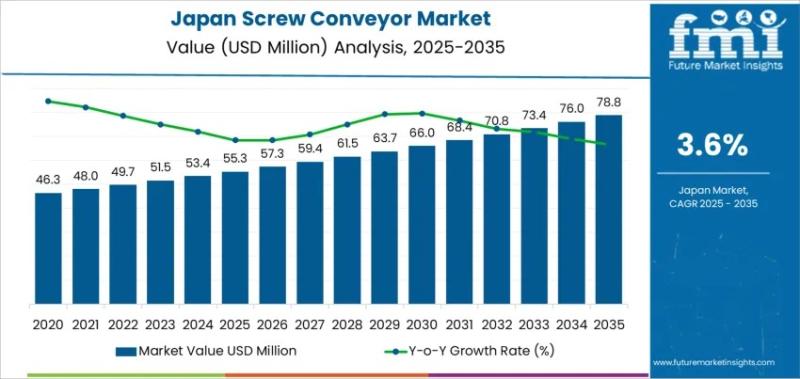

Japan Screw Conveyor Market Growth Outlook 2025-2035 Driven by Automation and In …

The Demand for Screw Conveyor in Japan is gaining steady momentum as the country accelerates automation across manufacturing, food processing, chemicals, and construction. According to recent market data, demand is projected to rise from USD 55.3 million in 2025 to USD 78.8 million by 2035, reflecting a compound annual growth rate (CAGR) of 3.6%. This growth highlights the increasing importance of efficient bulk material handling solutions in Japan's evolving industrial…

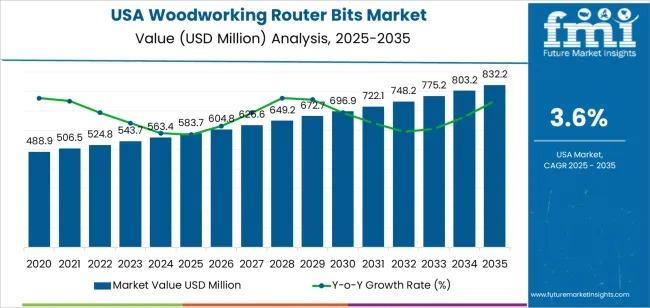

USA Woodworking Router Bits Market Outlook 2025-2035: Steady Growth Backed by DI …

The USA woodworking tools industry is witnessing a period of stable, value-driven expansion, with router bits emerging as a critical component of precision wood processing. According to recent industry analysis, the Demand for Woodworking Router Bits in USA is forecast to increase from USD 583.7 million in 2025 to USD 832.2 million by 2035, registering a compound annual growth rate (CAGR) of 3.6%.

This sustained growth reflects rising activity across residential…

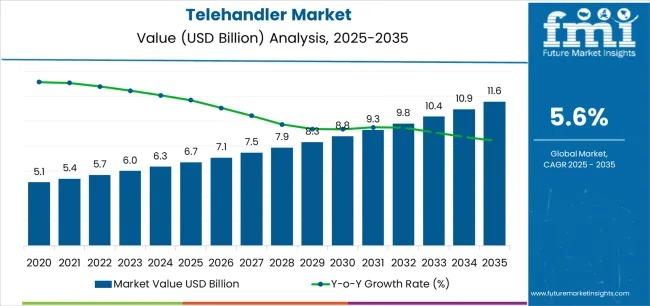

Telehandler Market to Reach USD 11.6 Billion by 2035, Growth Driven by Construct …

The global Telehandler Market is estimated at USD 6.7 billion in 2025 and projected to reach USD 11.6 billion by 2035, growing at a CAGR of 5.6%. This steady growth reflects the increasing demand for versatile lifting and material handling equipment across construction, agriculture, and industrial applications. Telehandlers are gaining traction for their ability to combine the functionalities of forklifts, cranes, and loaders-offering operational flexibility and cost savings across industries.

Subscribe…

More Releases for Lubricants

Indonesia Lubricant Market Expected to Surpass USD 4.36 Billion Mark by 2031 | M …

USA, New Jersey: Verified Market Research reports that the global IIndonesia Lubricant Market size was valued at USD 2.46 Billion in 2024 and is projected to reach USD 4.36 Billion by 2032, growing at a CAGR of 7.4% from 2025 to 2032. This steady growth is driven by increasing environmental regulations, rising awareness of pollution control, and expanding applications in industries such as manufacturing, energy, and healthcare.

Indonesia Lubricant Market -…

India Industrial Lubricants Market Drivers: Apar Industries, Valvoline Cummins, …

The India industrial lubricants market is poised for significant expansion, with its valuation anticipated to climb from an estimated USD 59.4 billion in 2025 to a remarkable USD 86.8 billion by 2035, exhibiting a Compound Annual Growth Rate (CAGR) of 3.8%. This impressive trajectory is fundamentally driven by increased domestic manufacturing, substantial infrastructure investment, and rising awareness of predictive maintenance practices across key industries such as steel, cement, textiles, and…

Biodegradable Lubricants Will Support Demand for Agricultural Lubricants

The material known as a lubricant is used to lessen friction or abrasion between two surfaces that are in touch with one another. It is accessible in solid, liquid, and gaseous states and aids in the removal of heat and the transition of power.

Semisolid versions of them can also be discovered. Grease is one of the most typical types of lubricants in a semisolid form. To boost productivity, lubricants are…

Commercial Vehicle Lubricant Market Top Key Players – Repsol, Castrol, ELF Ind …

Lubricants are essential for modern life. Thanks to the sophisticated oil and grease integration, car engines and transmissions run smoothly.

Lubricants are great fluids. Irrespective of weather conditions, engine oil must operate reliably in the temperature range of 40°C to 250°C or higher (piston ring upper temperature). It must also withstand pressures of 105 to 109 Pascals and contaminants such as metal particles and soot.

Lubricants perform the main functions of…

Commercial Vehicle Lubricant Market Top Key Players – Repsol, Castrol, ELF Ind …

Lubricants are essential in modern life. Car machines and gearboxes run smoothly through the integration of advanced oils and fats. Lubricants are remarkable liquids. Regardless of the weather conditions, the engine oil must operate reliably at temperatures of 40 ° C to above 250 ° C - the temperature near the upper piston ring. It also has to deal with presses between 105 and 109 Pascacakes as well as contaminants,…

Commercial Vehicle Lubricant Market Top Key Players – Repsol, Castrol, ELF Ind …

Lubricating oils are essential to modern life. Automotive engines and gearboxes run smoothly due to the sophisticated oil and grease integration. Lubricating oil is an amazing fluid. Regardless of weather conditions, engine oil should operate stably at temperatures in the range of 250 ° C and above (the temperature near the upper piston ring) at 40 ° C. It also deals with pressures between 105 and 109 Pascals, as well…