Press release

Blow Molding Resins Market by Type, Application and Region – 2023 | BASF SE, Eastman Chemical, LyondellBasell Industries Holdings B.V., DowDuPont, SABIC, Exxon Mobil, INEOS, China Petrochemical, Formosa Plastics, Chevron, Lanxess, Reliance and LG Chem

Blow Molding Resins Market: High demand from Packaging Industry across the globe is set to drive the global market

Some of the manufacturers operating in the Global Blow Molding Resins Market are BASF SE (Germany), Eastman Chemical Company (U.S.), LyondellBasell Industries Holdings B.V. (Netherlands), DowDuPont (U.S.), SABIC (Saudi Arabia), Exxon Mobil Corporation (U.S.), Solvay (Belgium), INEOS (Switzerland), China Petrochemical Corporation (China), Formosa Plastics Group (Taiwan), Chevron Corporation (U.S.), Versalis S.p.A. (Italy), Lanxess (Germany), Reliance Industries Limited (India), and LG Chem (South Korea).

Get In-Depth Sample Report @ https://www.marketresearchfuture.com/sample_request/6127

Regional Analysis

Regionally, the Global Blow Molding Resins Market is segmented into five regions namely Asia Pacific, North America, Europe, Latin America, and the Middle East & Africa.

Asia Pacific dominated the Global Blow Molding Resins Market in 2017 on account of the high demand for blow molding resins from major end-use industries such as packaging, automotive, construction, electronics, and others.

Europe accounted for the second largest market share in 2017 owing to the production and exportation of lightweight automotive parts in the region.

North America is expected to witness a considerable growth due to high demand from the food & beverage packaging industry.

Blow Molding Resins Market Segmentation

The Global Blow Molding Resins Market is segmented by a Molding Process, Type, End-Use Industry and Region.

On the Basis of the Molding Process, the market is segmented into extrusion, injection blow molding, and injection stretch blow molding. Among these processes, the extrusion has primarily used the technique to produce a large variety of hollow parts or objects with thin walls. This can be attributed to the low tool and die cost, fast production rates, and its capability of manufacturing different types of plastic products with different shapes, sizes, and neck openings. Products of different shapes such as T-section, U-section, L-section, square, and circular section can be produced by employing this technique. Bottles, industrial parts, automotive parts, watering cans, toys, appliance components are some of the products manufactured through extrusion. Injection blow molding is expected to be the fastest emerging as it enables the production in shorter time, although it is highly expensive and consumes a lot of space.

A broad range of resins is available in the market such as polyethylene, polypropylene, polyethylene terephthalate, acrylonitrile butadiene styrene, polyvinyl chloride, nylon/ polyamides, polycarbonate, and others. The polyethylene is the dominating the market due to its use in a wide range of products, depending upon its density. HDPE is used for shampoo and motor oil containers, fuel tanks, industrial drums, and others. It is chemically inert, translucent, easily colored, recyclable, and molder-friendly. With the same properties, LDPE is used for plastic bags, squeeze bottles, among others. The demand for PET is mainly driven by its use in bottling applications for mineral water and other beverages. Moreover, recent R&D for a bio-based PET is likely to offer substantial opportunities in the global market. The use of ABS in automotive decreases the overall weight of the vehicle by 10%, which is the major factor propelling the product demand. On the other hand, polypropylene has lower density and is usually used in elevated temperature for medical parts that need autoclave sterilization, which is expected to boost the product demand over the review period.

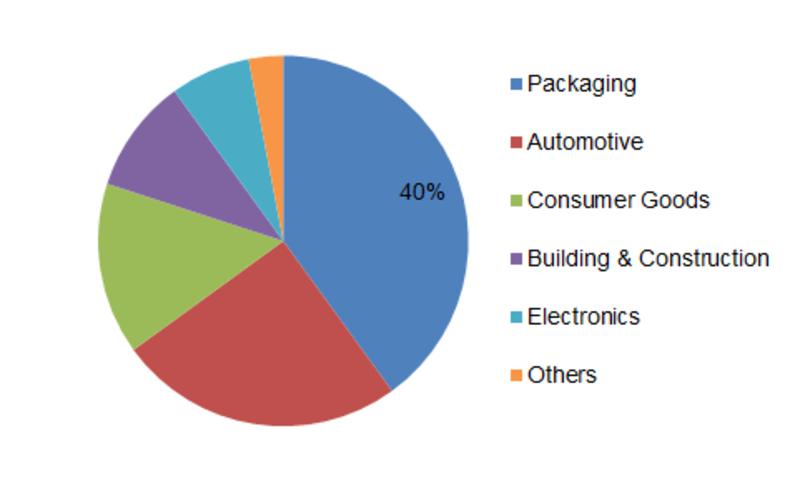

Among the End-Use Industry Segment, the packaging is leading the Global Blow Molding Resins Market. The shifting trend towards the usage of plastic products instead of conventional materials such as wood and metal for packaging is likely to fuel the demand over the forecast period. This is primarily due to their recyclability and biodegradability, which is one of the major concerns. The rise in trade of lightweight and durable automotive and consumer electronics is expected to fuel the product demand during the review period.

Get Complete Report @ https://www.marketresearchfuture.com/reports/blow-molding-resins-market-6127

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by Components, Application, Logistics and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Contact:

Market Research Future

+1 646 845 9312

Email: sales@marketresearchfuture.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Blow Molding Resins Market by Type, Application and Region – 2023 | BASF SE, Eastman Chemical, LyondellBasell Industries Holdings B.V., DowDuPont, SABIC, Exxon Mobil, INEOS, China Petrochemical, Formosa Plastics, Chevron, Lanxess, Reliance and LG Chem here

News-ID: 1455507 • Views: …

More Releases from Market Research Future

Travel Insurance Market Size to Reach USD 64.06 Billion by 2035 Driven by Rising …

The Travel Insurance Market report provides detailed insights into market trends, competitive landscape, growth drivers, and opportunities across global regions.

Travel Insurance Market Overview

The Travel Insurance Market is witnessing significant growth due to the increasing number of international travelers, rising awareness of travel-related risks, and demand for comprehensive insurance coverage. Travel insurance offers protection against trip cancellations, medical emergencies, baggage loss, and travel-related accidents. The Travel Insurance Market Size was estimated…

Digital Payment Market Size to Reach USD 524.28 Billion by 2035

The Digital Payment Market report provides comprehensive insights into market trends, competitive landscape, growth drivers, and opportunities across global regions.

Digital Payment Market Overview

The Digital Payment Market is witnessing rapid growth due to the increasing adoption of cashless transactions, e-commerce expansion, and technological advancements in financial services. Digital payment solutions offer convenience, speed, and security for consumers and businesses, reshaping the global payment ecosystem. The Digital Payment Market Size was estimated…

Title Insurance Market Size to Reach USD 5.893 Billion by 2035 with Steady Growt …

The Title Insurance Market report provides comprehensive insights into market trends, competitive landscape, growth drivers, and opportunities across global regions.

Title Insurance Market Overview

The Title Insurance Market is experiencing steady growth, driven by increasing real estate transactions, regulatory requirements, and rising demand for property ownership protection. Title insurance protects property buyers and lenders against potential legal disputes, liens, or defects in property ownership. The Title Insurance Market Size was estimated at…

Smart Personal Safety Security Device Market Size to Reach USD 15.28 Million by …

The Smart Personal Safety Security Device Market report provides detailed insights into market trends, competitive landscape, growth drivers, and opportunities across global regions.

Smart Personal Safety Security Device Market Overview

The Smart Personal Safety Security Device Market is witnessing strong growth as individuals and organizations increasingly adopt advanced security solutions for personal and home safety. These devices include wearable alarms, smart locks, personal GPS trackers, and connected monitoring systems that enhance user…

More Releases for Molding

Differences Between Flaskless Molding Machines and Flask Molding Machines

Flaskless molding machines [https://www.junengmachinery.com/servo-molding-machine-products/] and flask molding machines are two primary types of equipment used in foundry production for making sand molds (castings molds). Their core distinction lies in whether they use a flask to contain and support the molding sand. This fundamental difference leads to significant variations in their processes, efficiency, cost, and applications.

Key Differences

Core Concept:

Flask Molding Machine: Requires the use of a flask during mold making. A flask…

LSR Molding: Understanding Silicone Rubber Injection Molding

Liquid Silicone Rubber (LSR) molding is a specialized manufacturing process used to create flexible, durable, and heat-resistant silicone parts. This technique is widely used across industries such as automotive, medical, electronics, and consumer goods. Its ability to produce high-quality parts with precision and consistency makes it a top choice for many manufacturers.

• What Is LSR Molding?

LSR molding, or Liquid Silicone Rubber injection molding (https://www.newtopcustomsilicone.com/capabilities/liquid-silicone-injection-molding/), involves injecting two-component platinum-cured silicone into…

HDPE Blow Molding and Injection Molding Containers Market

Persistence Market Research (PMR) has published a new research report on HDPE blow molding and injection molding containers. The report has been titled "HDPE Blow Molding and Injection Molding Containers Market: Global Industry Analysis 2013-2017 and Forecast 2018-2026." The proliferating demand for HDPE blow molding and injection molding containers is largely from the beverage, chemical & petrochemicals, and pharmaceuticals industries, owing to the barrier properties of HDPE and convenience in…

Sheet Molding Compound and Bulk Molding Compound Market - Growth Prophesy 2025 | …

Global Sheet Molding Compound and Bulk Molding Compound Market: Snapshot

The global market for sheet molding compound and bulk molding compound is expected to advance with the launch of superior quality, lightweight, and more durable bulk molding and sheet molding compounds. By virtue of their higher line throughputs and lower production costs, these compounds are increasingly preferred by several leading manufacturers. As an augmenting number of advanced automobiles and luxury brands…

HDPE Blow Molding and Injection Molding Containers Market 2026

Due to its intrinsic physical and mechanical properties, high density polyethylene (HDPE) is highly used as packaging materials in different industries including food, beverages, pharmaceuticals, cosmetics, homecare, chemicals, and petrochemicals. Urbanization, changing consumer preferences, and expanding middle class have significantly contributed to the rising demand for consumer goods. Increased demand for consumer goods has, in turn, revolutionized the packaging industry, especially plastic packaging.

Polyethylene is most commonly used in the packaging…

Sheet Molding Compound and Bulk Molding Compound Market 2017-2025 : Polynt S.P.A …

Global Sheet Molding Compound and Bulk Molding Compound Market: Snapshot

The global market for sheet molding compound and bulk molding compound is expected to advance with the launch of superior quality, lightweight, and more durable bulk molding and sheet molding compounds. By virtue of their higher line throughputs and lower production costs, these compounds are increasingly preferred by several leading manufacturers. As an augmenting number of advanced automobiles and luxury brands…