Press release

Cutting Wheels Market Value Share, Analysis and Segments 2018 to 2028

With a steady estimated growth rate of the cutting wheels market in the foreseeable future, manufacturers are focusing on demand-driven machine developments that deliver optimum cutting duration, changeover frequency, and lower time to perform cutting wheel changeover. As end-users give preference to higher productivity, lower downtime and lower overall production cost, preference for high-priced and high-performance cutting wheels dominates the market.Request Report Sample @ https://www.factmr.com/connectus/sample?flag=S&rep_id=534

With the frequent amalgamation across industries, the versatility of cutting wheels has become a prerequisite for cutting different types of materials. To accommodate these evolving industry standards, manufacturers in the cutting wheels market deliver one-size-fits-all options along with the exclusive material cutting wheels. Leading market players such as Precision and Telematics Solutions are delivering training programs and specialized services for operators as cutting techniques affect the cutting wheel performance.

Introduction of novel products is frequent in the cutting wheels market. For instance, Weiler Abrasives Group, a leading player in the cutting wheels market has launched a new series of Tiger® Aluminum cutting wheels, grinding wheels and combo wheels with reduced changeover time and lower cost. Further, with the increasing importance of metallographic processes where cutting plays a vital role, cutting wheels market is set to grow steadily in the future.

Cutting Wheels Market: Introduction

Cutting wheels are thin metal wheels with sharp circumferential edges. These wheels are made from various materials, such as cast iron, steel, nickel, alloy, titanium, aluminum, etc. as well as stones and ceramics. The material is chosen on the basis of application. Cutting wheels are broadly used in many industries, such as aerospace, automotive, foundries, fabrication, ship-building and construction. These cutting tools are of great help in areas where parting of metal sheets or pipes is required. Cutting and grinding wheels are normally arbor-mounted and are of various types, such as diamond, metal & abrasive cutting wheels. Abrasives are used to coat cutting wheels. The type of abrasive used and the shape and grit of the wheel help define which material can be best cut using the applied formats.

Wheels with lower grit numbers are suitable for rough grinding and make the process faster. When a higher grit number is used, the process becomes considerably slower. However, higher grit number ensures smoother finish. The style of a cutting wheel informs customers about its applications. Some cutting wheels are designed to cut and notch the work piece. Cutting wheels are available in the market with a wide range of specifications. The market demand for cutting wheels will grow as these wheels are used in a variety of applications. Manufacturers can harp on the opportunities created and create a brand for themselves by introducing more reliable cutting wheels that can serve their purpose by getting the job done swiftly and accurately.

Request for Brochure @ https://www.factmr.com/connectus/sample?flag=B&rep_id=534

Cutting Wheels Market: Market Dynamics

The market for cutting wheels is expected to stay promising in the years to come. The main market drivers will be the booming metal and construction industries. With never ending scope for the consumption of cut metal pipes, TMT steel rods and HYSD (High Yielding Strength Deformed) bars, which find usage in the construction industry in the form of Rebar (Reinforced Bar), the growth of the construction industry will add considerably to the growth of the cutting wheels market. The market for cutting wheels is expected to grow at a significant rate due to their high rate of replacement. A typical cutting wheel lasts for only 5-8 17” cuts, thereby calling for better replacement rates. Diamond abrasives are being increasingly used to cut metal bars and concrete in today’s market. This is expected to further enhance the growth of the market in the coming years and is expected to set a trend in the cutting wheels market.

With growing rate of construction and metal cutting in various end-use industries, the market is expected to rise with significant CAGR throughout the forecast period. However, there are a few restraints in the market. Cutting wheels are being replaced by various other methods of cutting metal and cement, such as plasma cutting, laser cutting, water jet and burning. The main reason behind this shift is the ease of operation provided by the above said cutting processes. Although these methods are popular, due to their high cost of installation and maintenance, most of the masons prefer the conventional way of cutting, which offers better accuracy with smooth finishes.

Request TOC of this Report @ https://www.factmr.com/connectus/sample?flag=T&rep_id=534

About Fact.MR

Fact.MR is a fast-growing market research firm that offers the most comprehensive suite of syndicated and customized market research reports. We believe transformative intelligence can educate and inspire businesses to make smarter decisions. We know the limitations of the one-size-fits-all approach; that's why we publish multi-industry global, regional, and country-specific research reports.

Contact us

Fact.MR

353-1-6111-593

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Email: sales@factmr.com

Web: https://www.factmr.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Cutting Wheels Market Value Share, Analysis and Segments 2018 to 2028 here

News-ID: 1429466 • Views: …

More Releases from Fact.MR

Snacks Market is Growing at USD 569.2 billion in 2025 | Fact.MR Report

The global snacks market is projected to grow from USD 545.2 billion in 2026 to approximately USD 835.4 billion by 2036. This growth reflects a steady compound annual growth rate (CAGR) of 4.3% over the ten-year forecast period. The market is being fundamentally reshaped by the "snackification" of meals, where busy consumers are increasingly replacing traditional breakfast, lunch, and dinner with portable, nutrient-dense snacking options.

Get Access of Report Sample: https://www.factmr.com/connectus/sample?flag=S&rep_id=50

Quick…

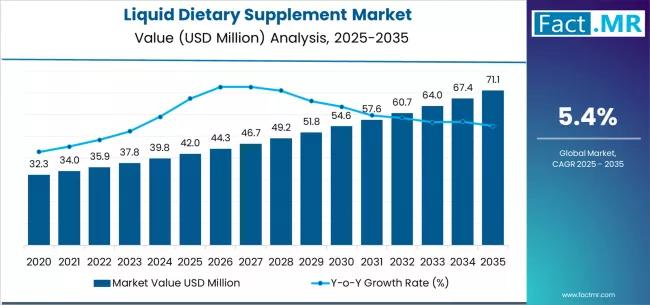

Liquid Nutritional Supplement Market Growing from USD 42.0 billion in 2025 to US …

The global liquid Nutritional supplements market is projected to grow from USD 33.25 billion in 2026 to approximately USD 45.10 billion by 2036. This growth represents a compound annual growth rate (CAGR) of 6.1% to 10.2% depending on the specific product segment (e.g., high-growth Ready-to-Drink formulations vs. traditional tonics).

The market is being primarily driven by a "pill fatigue" trend among consumers and an aging global population that increasingly prefers…

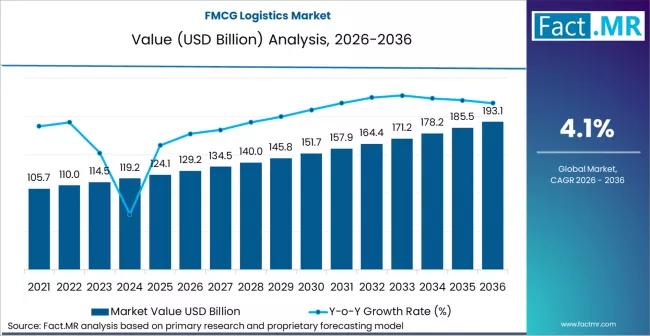

FMCG Logistics Market is Expected to Hit USD 190.5 billion by 2036 | Fact.MR Ins …

The global FMCG logistics market is projected to grow from USD 126.9 billion in 2026 to approximately USD 189.5 billion by 2036. This growth reflects a steady compound annual growth rate (CAGR) of 4.1% over the ten-year forecast period.

The market is entering a decade of transformation, shifting from a focus on cost-driven efficiency to automation-led resilience as retailers and brands navigate the complexities of quick-commerce and global supply chain…

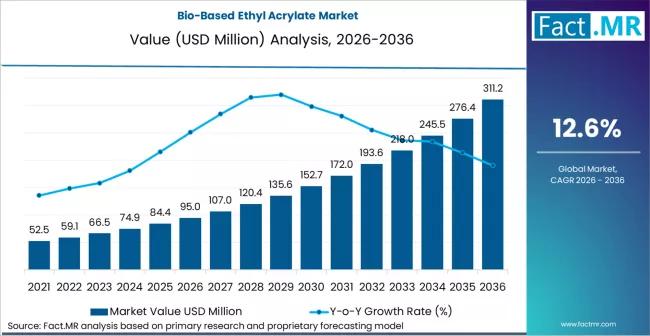

Bio-Based Ethyl Acrylate Market Forecasted CAGR of 12.6% by 2036 | Fact.MR Repor …

The global Bio-Based Ethyl Acrylate Market is projected to expand significantly over the next decade as demand for sustainable, performance-oriented monomers rises across coatings, adhesives, textiles, and specialty chemical applications. Industry analysts estimate that the market, valued at approximately USD 450 million in 2025, is expected to reach around USD 940 million by 2035, representing a compound annual growth rate (CAGR) of about 7.9% over the forecast period.

Get Access of…

More Releases for Cutting

Comparing CO2 Laser Cutting to Other Fabric Cutting Methods

Choosing the Right Tool for Precision and Efficiency

Choosing the correct focal length for your CO2 laser is crucial for achieving precise cuts, especially when working with laser cutting fabric. The focal length determines the laser beam's spot size and depth of focus, directly impacting cutting quality. Shorter focal lengths (e.g., 1.5" to 2") are ideal for fine details on thin materials, while longer focal lengths (e.g., 4" to 5") suit…

Cutting Edge Solutions: Analyzing the Booming Cutting Fluid Market

The global cutting fluid industry is poised for significant growth, with projections indicating a Compound Annual Growth Rate (CAGR) of 4.1% from 2023 to 2033. By 2033, the market is expected to achieve a valuation of USD 16.3 billion, underscoring its critical role in industrial manufacturing and machining processes.

Cutting fluids, often referred to as coolants or lubricants, play a pivotal role in industrial metalworking. These fluids are designed to reduce…

Is Die Cutting The Same As Cricut? What Is The Difference Between Die Cutting An …

Die cutting and Cricut are related but not exactly the same. Die cutting is a general term for the process of using a die to cut out shapes from various materials, such as paper, fabric, or metal. This can be done manually with a die cutting machine or press, or with the help of electronic die cutting machines like the Cricut.

Cricut is a brand of electronic die cutting machines that…

Profboard launches cutting-edge cutting board on Kickstarter

Image: https://www.getnews.info/wp-content/uploads/2024/06/1718783865.png

Revolutionizing Kitchen Safety and Convenience for Home Chefs

Profboard, the premier manufacturer of innovative cutting board systems, is proud to announce the launch of the Profboard Private edition. Since 2006, Profboard has been a trusted name among chefs and culinary enthusiasts worldwide. Now, the same professional-grade quality and innovation can be experienced in home kitchens.

Profboard sets a new standard with its cutting-edge cutting board system designed to revolutionize your kitchen.…

Fiber Laser Metal Cutting Machines Market Cutting-Edge Technology for Efficient …

Global Fiber Laser Metal Cutting Machines Market Overview:

The Fiber Laser Metal Cutting Machines market is a broad category that includes a wide range of products and services related to various industries. This market comprises companies that operate in areas such as consumer goods, technology, healthcare, and finance, among others.

In recent years, the Fiber Laser Metal Cutting Machines market has experienced significant growth, driven by factors such as increasing consumer demand,…

Metal Cutting Fluids Market Report 2018: Segmentation by Type (Emulsion Metal Cu …

Global Metal Cutting Fluids market research report provides company profile for Blaser, Idemitsu Kosan, Daido Chemical Industry, COSMO Oil, Master, Exxon Mobil Corporation, Houghton (Gulf Oil), BP, Fuchs, Yushiro Chemical, Quaker and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for…