Press release

Vacuum Measurements directly at the Process Chamber with the THERMOVAC TM101 Vacuum Gauge

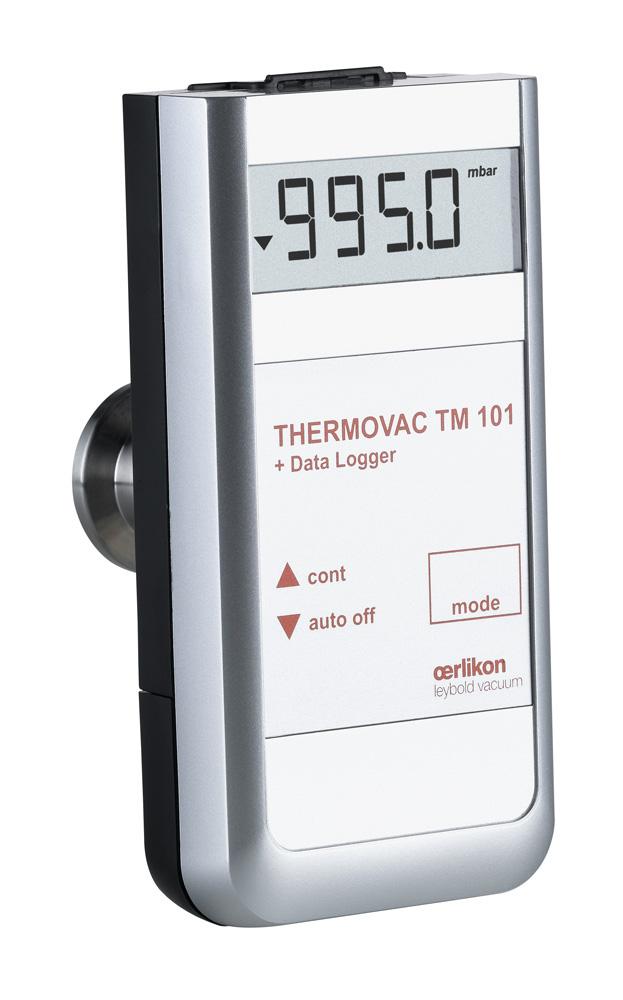

The new digital THERMOVAC TM101 vacuum gauge from Oerlikon Leybold Vacuum offers a new method of directly measuring the vacuum pressure in the vacuum chamber. The measurement data is acquired through the hand set TM101 and can be processed further using software.The THERMOVAC TM101 hand set permits vacuum measurements spanning seven decades (1200 to 5 x 10-4 mbar). Moreover, the TM101 offers the possibility of an adjustable gas correction factor, a minimum and maximum memory function and pressure measurements independent of the type of gas above 15 mbar.

The data logging function is capable of transferring 2000 measurement records from the internal memory via the USB interface to a PC. The VacuGraph pressure function. The measurement data can subsequently be exported by way of an ASCII file to Microsoft Excel, for example.

Modern enterprises use the TM101 for checks as well as to ensure operation and for quality assurance of vacuum systems. The rugged, handy TM101 which is insensitive to humidity (IP40) is also ideal for servicing and maintenance assignments.

A practical application example is the utilisation of this unit in vacuum packaging in the foodstuff industry. The TM101 may be affixed to the package with or without the foodstuff. When evacuating the air inside the package, the TM101 automatically starts to record the pressure. The measurement data is then indicated on the display or optionally only the minimum and maximum values are indicated. The up to 2,000 measurement records may then subsequently be visualised and processed further through the VacuGraph software. Thus, the pressure conditions in a package can be checked for a maximum period of 75 hours and thereafter documented by way of quality assurance records. Deviating pressure values or leaks in the packages can therefore be determined quickly.

The TM101 is also used on coating systems, in the area of chemical process engineering, in refrigeration and air conditioning systems prior to charging and in the manufacture of refilling of bulbs and lamps with pressurised gas.

The protection case has been designed to safely accommodate the accessories including a wide voltage range power supply unit for long-term measurements, interface cable and VacuGraph software.

Oerlikon (SWX: OERL) is among the world's most successful industrial high-tech companies focusing on machine and systems engineering. Oerlikon stands for leading industrial solutions and cutting-edge technology in textile production, thin-film solar, thin film coating, propulsion, vacuum and solar technology, as well as Advanced Technology. As a company with Swiss roots, over 150 years of business tradition and approx. 16,000 employees at 157 locations in 36 countries, Oerlikon has evolved into a global player today with sales amounting to CHF 2.9 billion in 2009. The group invests annually over CHF 200 Mio. in research and development. More than 1200 specialist design products for tomorrow. The group is ranked first or second in each of its respective market.

Oerlikon Leybold Vacuum offers a broad range of advanced vacuum solutions for use in manufacturing and analytical processes, as well as for research purposes. The Segment’s core capabilities center on the development of application- and customer-specific systems for the creation of vacuums and extraction of processing gases. Field of application is the semiconductor industry, thin films and data storage, analytical instruments and the classic industrial processes.

Oerlikon Leybold Vacuum GmbH

Bonner Strasse 498

D-50968 Köln

Phone: +49 (0) 221 347-1261

Fax: +49 (0) 221 347-31261

christina.steigler@oerlikon.com

www.oerlikon.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Vacuum Measurements directly at the Process Chamber with the THERMOVAC TM101 Vacuum Gauge here

News-ID: 141981 • Views: …

More Releases from Oerlikon Leybold Vacuum GmbH

Oerlikon Leybold vacuum technology and measuring equipment enables the proof of …

Vacuum technology promotes fundamental research

After about 100 years, it is a fact: Albert Einstein was right again. A century after the physicist predicted the existence of gravitational waves in the scope of his theory of general relativity, their existence has now been proved scientifically. The vacuum and measuring equipment of Oerlikon Leybold Vacuum has provided an important contribution to this discovery of American and German space scientists being worthy of…

Oerlikon Leybold Vacuum Supplies Vacuum Systems for the COPT.Zentrum of the Univ …

International top level in and out of Cologne

For the University of Cologne, the COPT.ZENTRUM is a central element of their technology transfer strategy from science to practice. Small and middle-sized companies will benefit from the premises of the center, the technology, and the newest scientific findings in the field of organic electronics. Oerlikon Leybold Vacuum supplies the necessary vacuum technology.

After two years of construction, the building, which was financed with…

WELTEC Biomethane Plant in France Launches Feed-in

Leading Edge with Processing Technology

On 5 August, the „Longchamps“ biomethane plant in the Franche-Comté region in eastern France went live. Thus, 70 standard m3/h are now continually supplied to the natural gas grid of the French gas distributor GrDF (Gaz réseau Distribution France). Plant operator David Peterschmitt uses about 6,000 t of agricultural leftovers a year for the production of biogas from anaerobic digestion.

To ensure effective biogas processing, German plant…