Press release

Loss-in-Weight Feeder Market Segmented By types Volumetric loss-in-weight feeder and Gravimetric loss-in-weight feeder; By parts Hopper, Feeder, Weighing; By feeding ranges Small feeding range, Medium feeding range; By end-user industry Food Industry, Che

Loss-in-Weight Feeder Market IntroductionLoss-in-weight feeders are flexible and can handle bulk solids, liquids and other flowing products, used for both small and medium feeding ranges. Loss-in-weight feeders work under extreme pressure and in ambient conditions. The design depends on usage and vary from compact constructions to flexible concepts. The loss-in-weight feeders generate a controlled, fixed mass flow, as per the requirement in the mixing processes. These loss-in-weight feeders are used in various end-use industries such as the food industry and different laboratories. Various systems such as pneumatic conveyors are used to refill the loss-in-weight feeders. All the materials, feeder and hopper in the loss-in-weight feeder are continuously weighed during the operation.

The dominant application of loss-in-weight feeders is for collecting materials out of a storage vessel. The material stored in the hopper is refilled according to the rate at which it discharges so that the feeder never gets empty. The loss-in-weight feeders also helps in controlling the flow of solid fuels with high accuracy, at a comparatively lower cost. These factors altogether contribute towards the growth and demand for the loss-in-weight feeders in the various end-use industries across the world.

Request 100 Page Sample Report Now: https://www.factmr.com/connectus/sample?flag=S&rep_id=2012

Loss-in-Weight Feeder Market Dynamics

The key factor which drives the loss-in-weight feeders market is the constant growth and development in the various sectors and industries such as food, chemical, pharmaceutical and construction is set to push the loss-in-weight feeders market. Also increasing consumer preferences towards the improvement of quality and easy handling of the product will fuel the demand across various applications such as food, construction and chemical. In addition to this, manufacturers are focused on improving the designs to make it robust, durable and reliable. Consequently, increasing technologies for reducing power outages is continuously encouraging the need for automation.

The innovations in products and rapid growth of technology are also the key factors influencing the growth of the loss-in-weight feeders. For easy and quick production and packaging, the weighing and filling equipment must be clean, easy-to-handle and flexible. In the manufacturing processes, loss-in-weight feeders help to do the work precisely and quickly. Apart from this, the size and the cost of installing and maintaining the loss-in-weight feeders in industrial applications act as a restraint in the global loss-in-weight feeders market.

Loss-in-Weight Feeder Market Regional Overview

The regional demand for Loss-in-Weight Feeder varies across the globe. North America is the primary region for the manufacturing of the pharmaceutical industries, as these loss-in-weight feeders are required for the feeding and weighing in the pharmaceutical industries. There is a growth opportunity for the loss-in-weight feeders market in the North America region.

In APEJ, in countries such as India and China, the construction sector is growing at a fast pace, which results in the growth of construction materials markets such as cement, bricks and other construction materials. The loss-in-weight feeders are essential for feeding raw materials that are required for making the correct mixture. This drives the demand for the global loss-in-weight feeders market.

In Europe and Japan, the chemical and food sectors are anticipated to foster the demand for the loss-in-weight feeders in the region.

Request For Brochure @ https://www.factmr.com/connectus/sample?flag=B&rep_id=2012

Loss-in-Weight Feeder Market Key Players

Some of the prominent key players in the global loss-in-weight feeder market are:

Merrick Industries Inc.

Gericke

Hapman

Acrison

Kubota

GIMAT

Schenk Process

Novatec

Plastore

This analytical research study imparts an all-inclusive assessment on the market, while propounding historical intelligence, actionable insights, and industry-validated & statistically-upheld market forecast. Verified and suitable set of assumptions and methodology has been leveraged for developing this comprehensive study. Information and analysis on key market segments incorporated in the report has been delivered in weighted chapters. A thorough analysis has been offered by the report on

Report Analysis @ https://www.factmr.com/report/2012/loss-in-weight-feeder-market

Compilation of authentic and first-hand intelligence, insights offered in the report are based on quantitative and qualitative assessment by leading industry experts, and inputs from opinion leaders & industry participants around the value chain. Growth determinants, macroeconomic indicators, and parent market trends have been scrutinized and delivered, coupled with the market attractiveness for each market segment encompassed. Qualitative impact of growth influencers on the market segments across regions has also been mapped by the report.

About FactMR

FactMR is a fast-growing market research firm that offers the most comprehensive suite of syndicated and customized market research reports. We believe transformative intelligence can educate and inspire businesses to make smarter decisions. We know the limitations of the one-size-fits-all approach; that's why we publish multi-industry global, regional, and country-specific research reports.

Contact Us

FactMR

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Email: sales@factmr.com

Web: www.factmr.com/

Follow Us on Linkedin: www.linkedin.com/company/factmr/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Loss-in-Weight Feeder Market Segmented By types Volumetric loss-in-weight feeder and Gravimetric loss-in-weight feeder; By parts Hopper, Feeder, Weighing; By feeding ranges Small feeding range, Medium feeding range; By end-user industry Food Industry, Che here

News-ID: 1377107 • Views: …

More Releases from Fact.MR

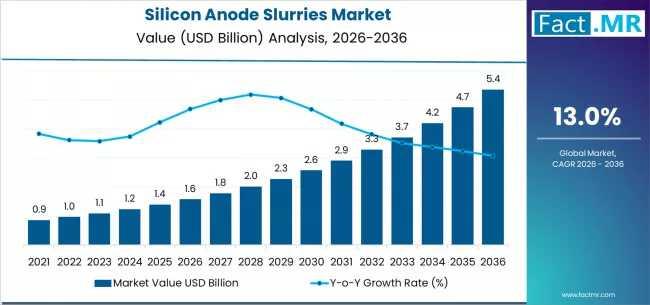

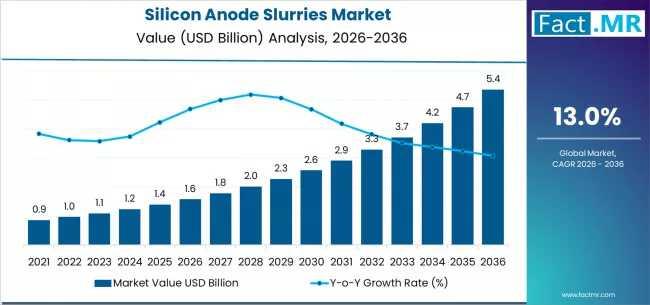

Silicon Anode Slurries Market Forecast 2026-2036: Market Size, Share, Competitiv …

The global silicon anode slurries market is set for significant expansion between 2026 and 2036, fueled by the rising adoption of high-energy-density lithium-ion batteries across electric vehicles (EVs), consumer electronics, and grid-scale energy storage. As battery manufacturers increasingly transition from graphite to silicon-enhanced anodes, the demand for high-performance, scalable silicon anode slurries is projected to grow sharply.

To access the complete data tables and in-depth insights, request a Discount On The…

Silicon Anode Slurries Market Forecast 2026-2036: Market Size, Share, Competitiv …

The global silicon anode slurries market is set for significant expansion between 2026 and 2036, fueled by the rising adoption of high-energy-density lithium-ion batteries across electric vehicles (EVs), consumer electronics, and grid-scale energy storage. As battery manufacturers increasingly transition from graphite to silicon-enhanced anodes, the demand for high-performance, scalable silicon anode slurries is projected to grow sharply.

To access the complete data tables and in-depth insights, request a Discount On The…

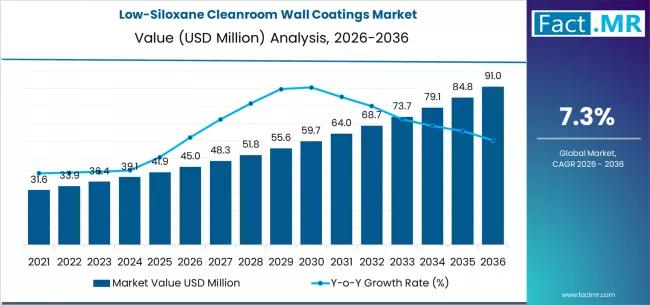

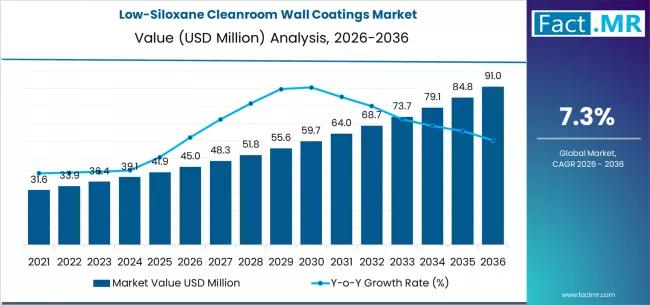

Low-Siloxane Cleanroom Wall Coatings Market Deep-Dive 2026-2036: Strategic Forec …

The low-siloxane cleanroom wall coatings market is poised for steady growth over the next decade, driven by rising contamination-control requirements across semiconductor, pharmaceutical, biotechnology, and precision manufacturing industries. These coatings are specifically engineered to minimize siloxane outgassing and volatile organic compound emissions, helping maintain ultra-clean environments where even trace contamination can disrupt production quality.

By 2036, the market for low-siloxane cleanroom wall coatings is expected to grow to USD 91.04 million.…

Low-Siloxane Cleanroom Wall Coatings Market Deep-Dive 2026-2036: Strategic Forec …

The low-siloxane cleanroom wall coatings market is poised for steady growth over the next decade, driven by rising contamination-control requirements across semiconductor, pharmaceutical, biotechnology, and precision manufacturing industries. These coatings are specifically engineered to minimize siloxane outgassing and volatile organic compound emissions, helping maintain ultra-clean environments where even trace contamination can disrupt production quality.

By 2036, the market for low-siloxane cleanroom wall coatings is expected to grow to USD 91.04 million.…

More Releases for Feeder

Vibratory Bowl Feeder Market Is Going to Boom |• RNA Automation • Hoosier Fe …

Worldwide Market Reports has added a new research study on "Vibratory Bowl Feeder Market" is projected to experience substantial growth in the coming years. This report provides a comprehensive analysis of the market landscape using an integrated approach that includes research methodology, market size evaluation, data compilation, and insights gathered from multiple credible sources.

The study covers critical market elements such as market dynamics, drivers, restraints, challenges, threats, growth opportunities, development…

Emerging Feeder Automation Market Trends: Technological Advancements in Feeder A …

Use code ONLINE30 to get 30% off on global market reports and stay ahead of tariff changes, macro trends, and global economic shifts.

Feeder Automation Market Size Growth Forecast: What to Expect by 2025?

In the past few years, the feeder automation market has seen robust growth. It is predicted to expand from $3.82 billion in 2024 to $4.11 billion in 2025, demonstrating a compound annual growth rate (CAGR) of 7.6%. This…

Emerging Feeder Automation Market Trend 2025-2034: Technological Advancements in …

How Is the Feeder Automation Market Projected to Grow, and What Is Its Market Size?

The market size for feeder automation has experienced significant expansion in the last few years. There is a projected increase from $3.82 billion in 2024 to $4.15 billion in 2025, showcasing a compound annual growth rate (CAGR) of 8.5%. This growth in the historical phase can be ascribed to fast increasing electricity prices, a rising demand…

Leaky Feeder System - Comprehensive Analysis

A leaky feeder system is a communications system used in underground mining, tunnels, railways, and among others. Leaky feeder system includes leaky feeder cables, connectors, distribution boxes, bi-directional amplifiers, head-end radio terminal equipment, digital/analog repeaters, etc. Growing construction activities across the globe is the major factor driving the growth of the leaky feeder system industry over the forecast period.

Get Sample Brochure at https://www.theinsightpartners.com/sample/TIPRE00012730/?utm_source=Openpr&utm_medium=10396

The requirement of communication systems in the underground…

Flower Bird Feeder Sherem Review 2023;(Must Read!) Is this Hummingbird Feeder wo …

Flower Bird Feeder Sherem consists of a container or reservoir filled with a specially prepared nectar solution.

The container is often made of plastic or glass and is designed with small feeding ports or tubes that allow hummingbirds to access the nectar.

Some feeders also have perches or feeding stations to provide additional support for the birds while they feed.

Flower Bird Feeder Sherems are created with the intention of attracting…

Smart Bird Feeder Sherem Review 2023;(Shocking Truth!) Fascinating Bird Feeder.

Smart Bird Feeder Sherem is a strange but endearing bird feeder with a 1080p camera.

The camera is positioned perfectly so that you can capture images and videos of the birds arriving at the feeder. The Smart Bird Feeder allows you to view the birds from your phone, unlike previous Sherem feeders.

These camera-equipped bird feeders frequently include Wi-Fi or Bluetooth technology, allowing users to connect to the camera from their smartphones,…