Press release

World novelty: Durable position measurement of hydraulic pistons

PVDF sensors can measure piston positions durably and inexpensive. By several one behind the other arranged sensors piston positions can be seized quasi-similarly.The patented procedure for the position control of pistons in hydraulic cylinders made a new generation possible of Low Cost sensors. So far position measurements for pistons in hydraulic cylinders are made by laterally attached ultrasonic sensors with ceramic(s) oscillators. In addition usually modified sensors become, how them admit from the material testing (NDT) are used. These sensors are usually manufactured as cylinders. These possess a planar coupling surface at the face. This front surface cannot rest upon however full-laminar the curved cylinder wall. The contact to the cylinder surface takes place only on a very narrow strip toward the cylinder expansion. The contact can be improved by a couple means somewhat. If these sensors are also pressed to large strength against the cylinder wall, inevitably the sensitive piezo-ceramic breaks. If the position measurement is implemented laterally at the cylinder, the position sensors stand more usually reject laterally outward. Well-known sensors are to be installed mechanically so far only by clips or welded on fastening spots. Further they are exposed to possible damages by their dimensions. The measurement of these sensors effected only point for point and is limited only to a position. The new patented sensor arrays made of PVDF foil rest upon against it flat the cylinder wall. The structure height amounts to less than 1 cm and by the housing and by the cable connection is essentially determined. These piezoelectric elements are attached laterally on the hydraulic cylinder. These elements are flexible and adapt to the curvature of the hydraulic cylinder. With several arrays from PVDF foil also longer distance can be seized. Available PVDF foils cover a temperature range of -40° C to +100° C, with sensors from copolymers are attainable a temperature range to 145° C. Thus the ultrasonic sensors developed in the new patented procedure can be used also for applications the higher application temperatures to require. New application type result for these sensors in the case of the monitoring of pipings of small dimensions. In the biotechnology and active substance production often residue control is in demand. With small flexible tubing sensors, which adapt to arbitrary pipe diameters, the monitoring of mini Plants is economically possible.

Contact:

IBJ Technology

Colkwitzer Weg 7

04416 Markkleeberg

phone:+49(0)3413380172

email: info@ibj-technology.de

http://www.ibj-technology.de

Company

In January 2003 IBJ -Technology as partner of the industry for the interests of the process measuring technique one based.

Owner of the engineer's office for innovative measuring technique is

Mr. Dipl.-Ing. (TH), Dipl.-Ing.-Oek. Frank- Michael Jäger.

Our activity and thus our experiences in the process measuring technique for fastidious applications justify themselves on one over 15 years activity in the project management and development in research establishments of the chemistry, the natural gas industry and the mining industry.

The practical use of measurement principles and sensor technologies under most difficult operating conditions is supplemented by one over 12 years advisory activities to the employment and the use from process measuring technique to the benefit of the customers within all ranges of the economy.

As independent and reliable partners of the industry we offer comprehensive solutions in all questions of the process measuring technique.

Particularly with fastidious applications of the ultrasonic technology we can repair problems with new solutions.

Many innovative solutions for measuring tasks in the most different industries were protected in a multiplicity by patents and utility models.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release World novelty: Durable position measurement of hydraulic pistons here

News-ID: 12997 • Views: …

More Releases from IBJ Technology

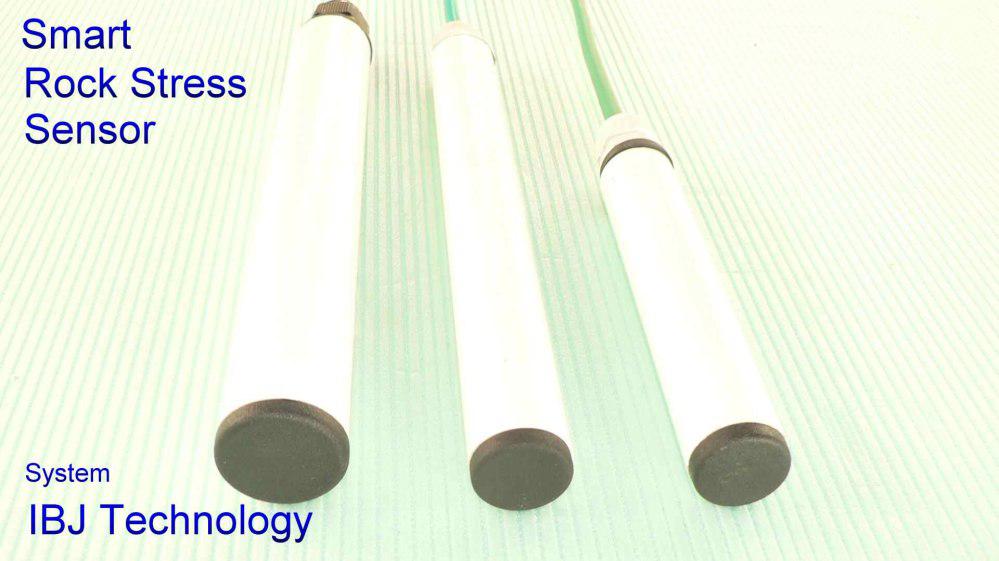

.Smart Rock Stress Sensor with MEMS

The RSS-X series of acousto elastic sensors from IBJ Techhnology is used to measure variations in compressive stress and load, which allows stress evaluation when the material’s modulus of elasticity is unknown or anisotropic and inhomogeneous. Typical examples are concretes and drill holes in the rocks, where these instruments can be used include:

• Mining

• Tunnel supports

• Deformations of pillars

• Dams and nuclear power plants

• Structural members of buildings and bridges

•…

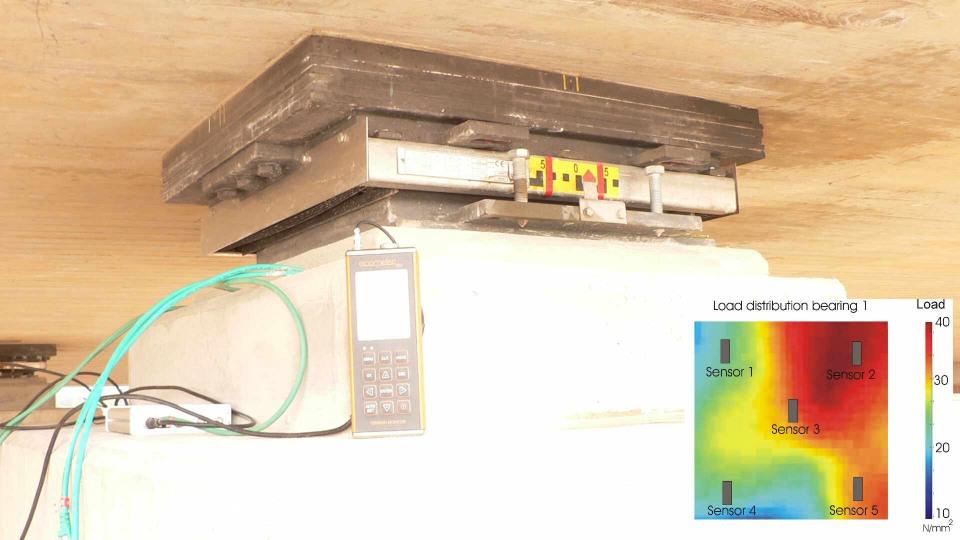

Smart Bridge - bridge bearings load control

The distribution can be determined of the load under bridge bearing load-bearing pillars or foundations with multiple sensors BBS 10_DS from IBJ technology. Uneven load entry can detect but also subsequently through still attached directly with sensors built into the bearing plate in the concrete.

The applications range from the direct voltage measurement in the component to the measurement and monitoring of dynamic loads in real time.

With the sensors is the…

Acousto-elastic concrete strain sensors for heavy duty applications

Acousto elastic concrete strain sensors are used to detect the metrological

Expansion or compression of steel building components as well as for measurements in reinforced and unreinforced concrete bodies used. The thickness of the susceptor (diameter of the bars) may be selected according to the strength reinforcement.

The acousto elastic concrete strain sensors can also be mounted on the outside parts of the structure of steel. With flanges or angle mounting is…

With high speed in the concrete

With the sensor BBS 10_DS from IBJ Technology, surface pressure in concrete components can be determined also afterwards. The applications range from the direct stress measurement in the component to the measurement and monitoring of dynamic loads in real time.

Ultrasonic captures the stress in the structure directly and in real time. All changes can be transferred online via the Internet or satellite radio. The sensors are either placed directly in…

More Releases for PVDF

Polyvinylidene Fluoride (PVDF) Latest Market Report 2026

According to our (Global Info Research) latest study, the global Polyvinylidene Fluoride (PVDF) market size was valued at US$ 5457 million in 2025 and is forecast to a readjusted size of USD million by 2032 with a CAGR of % during review period.

Global Info Research's report offers key insights into the recent developments in the global Polyvinylidene Fluoride (PVDF) market that would help strategic decisions. It also provides a…

PVDF Hollow Fiber Membrane Market Research Report

Global Info Research's report is a detailed and comprehensive analysis for global PVDF Hollow Fiber Membrane market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the PVDF Hollow Fiber Membrane market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles…

Global PVDF Hydrophone Market Outlook Report 2025

Global Info Research's report offers an in-depth look into the current and future trends in PVDF Hydrophone, making it an invaluable resource for businesses involved in the sector. This data will help companies make informed decisions on research and development, product design, and marketing strategies. It also provides insights into PVDF Hydrophone' cost structure, raw material sources, and production processes. Additionally, it offers an understanding of the regulations and policies…

PVDF Membrane Market Size, Share, Growth Forecast 2023-2032

In recent years, the global PVDF membrane market has witnessed significant growth, with a reported market size of USD 787 million in 2022. Projections suggest a robust trajectory, aiming for a market size of USD 1,579 million by 2032, reflecting a compelling Compound Annual Growth Rate (CAGR) of 7.4% from 2023 to 2032. In this article, we delve into the current market trends, drivers, opportunities, constraints, regional insights, and the…

middle east and africa polyvinylidene fluoride (pvdf) market

The research report "middle east and africa polyvinylidene fluoride (PVDF) Market: By Resin Type (Alpha, Beta, Delta and Gamma), By Application (Wires and Semicon Processing, Pipes and Fittings, Membranes, Li-ion Batteries, Films and Sheets and Coatings), By End User (Aerospace and Defence, Automotive and Transportation, Building and Construction, Chemical Processing, Electrical and Electronics and Oil and Gas), and Geography- Global/Region/Country Forecast to 2028." The Middle East and Africa polyvinylidene fluoride…

PVDF Market 2017 - Arkema, Solvay, Dyneon, Kureha, Dongyue Group

Apex Research, recently published a detailed market research study focused on the "PVDF Market" across the global, regional and country level. The report provides 360° analysis of "PVDF Market" from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global PVDF industry, and estimates the future trend of PVDF market on the basis of…