Press release

thyssenkrupp Materials Services is now “omnifit” – digital transformation of the materials business moves to the next level

• World’s biggest virtual warehouse: Virtual presentation of more than 150,000 products and services providing fully digital access to 3.5 million m² of storage space at 271 international operating sites• Omnichannel in practice: Cross-channel access to wide spectrum of materials and services for 250,000 customers worldwide

thyssenkrupp Materials Services is making rapid advances with its digital transformation: The thyssenkrupp Group’s materials experts are digitizing their entire range and consolidating it in the world’s biggest virtual warehouse. With more than 3.5 million square meters of storage space at 271 operating sites around the world, Materials Services is now closer than ever to its customers and offers round-the-clock access to more than 150,000 products and services through its new omnichannel structure, enabled by a powerful, self-developed AI (Artificial Intelligence) solution.

“Due to our holistic approach in the digital transformation of our business model, we have consistently and comprehensively created the important prerequisites over the last few years to enable the launch of innovative solutions. By digitally connecting our global inventories of roughly 150,000 products we can offer our customers the widest possible selection of our various materials and services and optimum availability 24/7,” says Hans-Josef Hoss from the Board of thyssenkrupp Materials Services. From plastics, steel products and nonferrous metals to diverse materials and supply chain management services – nowadays customers of thyssenkrupp Materials Services want customized access to the entire range. Hans-Josef Hoss: “In surveys and personal discussions we listened closely to what our customers want, and for more and more of them the ability to order our products and services however and above all whenever they need them is of key importance. Our omnichannel solution guarantees direct access to us and our products – anytime and anywhere.”

Tailored channels

Providing all required channels is key to the success of an omnichannel approach. At thyssenkrupp Materials Services customers can place orders via individual customer portals, EDI interfaces, online shops and in the future also via external platforms. “We digitize all our items and offer information in real time. Whether it’s just-in-time or just-in-sequence, customers will be able to order in line with their needs using the channel that’s most convenient to them. The focus is 100% on our customers and their requirements. That’s the basis for increasingly smart interaction in the future,” says Axel Berger, Head of Digital Transformation at thyssenkrupp Materials Services.

Positive experience with first customers has already been gathered during a practical trial. A new B2B portal as part of the omnichannel approach is already in use. It will go live in summer 2018. “After the official launch we will of course continue to make further optimizations and integrate customer feedback. Work on our highly complex omnichannel structure is an ongoing process as the digital transformation of thyssenkrupp Materials Services also is,” says Berger, who despite this also stresses the central role of personal contacts: “Alongside the new digital channels, the human factor – personal customer support by our experienced sales staff – will always be a key success factor for our business.”

Holistic approach

By starting to connect all its machinery last year with toii, thyssenkrupp Materials Services reached a key milestone in its digital transformation along the entire value chain. “To profit sustainably from the advantages of digitalization, it’s important to take a holistic approach. In addition to new, smart solutions in procurement – such as our new cloud-based purchasing platform – and sales, which are now served via our omnichannel strategy and the virtual warehouse, the intelligent digitalization of operating processes is also of key importance. Our IoT (Internet of Things) platform toii is an in-house development that allows machines of different types and ages to communicate with each other on a worldwide basis. In combination with our omnichannel approach this is leading to significantly faster and simpler coordination and planning processes. This is an effect which is substantially enhancing the efficiency of all players in the supply chain and a goal we will continue to work on in the future with the aid of new digital technologies,” says Hoss.

The video of thyssenkrupp Materials Services’ digital transformation is available here: https://youtu.be/3AI9Sdpbm3I

With around 480 locations in over 40 countries, the Materials Services business area specializes in materials distribution, logistics and services, the provision of technical services as well as services for industrial plants and steel mills. In addition to rolled steel, stainless steel, tubes and pipes, nonferrous metals, specialty materials and plastics, Materials Services also offers services from processing and logistics to warehouse and inventory management through to supply chain and project management.

Michael Ridder

thyssenkrupp Materials Services GmbH

Head of External & Internal Communications

Materials Services business area

www.thyssenkrupp-materials-services.com

Email: michael.ridder@thyssenkrupp.com

Telephone: +49 (201) 844- 534416

Twitter: @Michael23Ridder

Company blog: www.engineered-thyssenkrupp.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release thyssenkrupp Materials Services is now “omnifit” – digital transformation of the materials business moves to the next level here

News-ID: 1021864 • Views: …

More Releases from ins trade media service

Bio-Gate concludes another cooperation agreement with leading multinational impl …

Medical technology business further strengthened

Coating of orthopaedic revision implants with HyProtect technology

Focus on protection against infections with multi-resistant germs

Nuremberg/Bremen, 5 July 2022 - Bio-Gate AG (ISIN DE000BGAG981), a leading provider in the field of innovative health technologies, has concluded a contract with a leading multinational medical device manufacturer for the coating of orthopaedic implants in human medicine. As part of the cooperation and the joint project management, Bio-Gate is responsible…

Walki introduces a broad portfolio of recyclable materials for the growing froze …

Walki is answering to the growing demand for frozen food by expanding its portfolio of recyclable materials.

The global market for frozen food is expected to grow to 322 billion euros by 2026. Although the demand is growing globally across all age groups, it is especially popular among younger consumers.

"Frozen food is an ideal way to prolong shelf life without losing out on the vitamins. It is also an excellent way…

Dassiet and OrthoPets collaborate to provide safer and easier orthopedic care fo …

The teams combine Dassiet’s clinically proven medical and material innovations with OrthoPets' strong experience in custom pet orthoses to provide human level care for animals.

The material innovation company Dassiet, and the leading, US based pet orthosis manufacturer OrthoPets have started collaboration to create sustainable, safe and user-friendly pet healthcare products. Both companies want to first tackle the issues surrounding veterinary casting, splints, and bandages, and to provide vets, pets and…

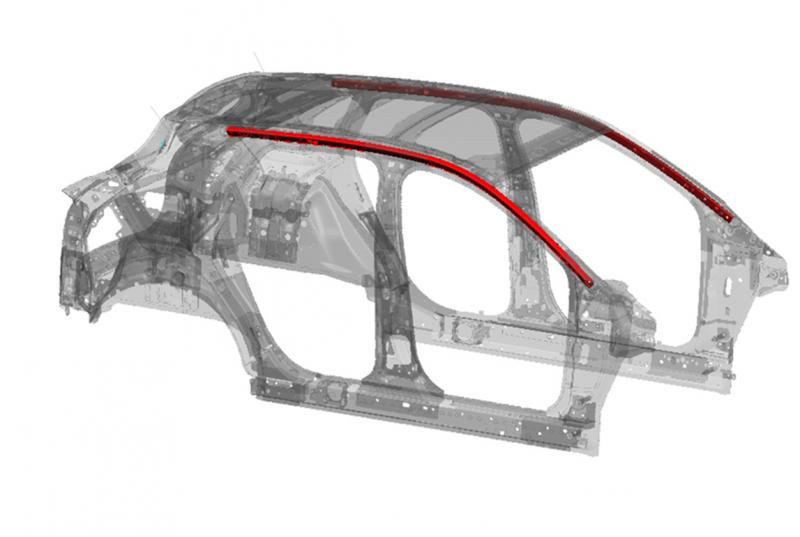

Shape Corp. wins Swedish Steel Prize 2019

The winner of the 20th international Swedish Steel Prize is Shape Corp. from the United States. The prize is awarded for the groundbreaking use of martensitic steel in a 3D formed tube for automotive roof rail applications.

“With great skill, Shape Corp. has shown the way forward and has succeeded in efficiently utilizing a modern material with the highest possible strength level. This shows a major opportunity in challenging other lightweight…

More Releases for Materials

Sustainable Tire Materials Market Sustainable Tire Materials Market

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global Sustainable Tire Materials Market- (By Type of Material (Rubber (Natural, Recycled), Sustainable Carbon Black, Silica, Others), By Propulsion Type (Internal Combustion Engine Vehicles, Electric Vehicles), By Vehicle Type, (Passenger Vehicles, Commercial Vehicles), By Tire Structure (Radial, Bias), By Sales Channel (OEMs, Aftermarket)), Trends, Industry Competition Analysis, Revenue and Forecast To 2034."

According to the latest research…

2D Materials Market Is Booming Worldwide |2D Materials, Nanotech, Advanced Mater …

HTF MI just released the Global 2D Materials Market Study, a comprehensive analysis of the market that spans more than 143+ pages and describes the product and industry scope as well as the market prognosis and status for 2025-2032. The marketization process is being accelerated by the market study's segmentation by important regions. The market is currently expanding its reach.

Major Giants in 2D Materials Market are:

Samsung, IBM, MIT, 2D Semiconductors,…

Elmet, HCStarck Solutions, Zhuzhou KJ Super Materials, Stanford Advanced Materia …

Global Info Research announces the release of the report "Global Tungsten Penetrator Market 2023 by Manufacturers, Regions, Type and Application, Forecast to 2029" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company…

Germanium (Ge) Evaporation Materials Market 2021 Strategic Assessment- Stanford …

The "Germanium (Ge) Evaporation Materials" Market report offers qualitative and quantitative insights and a detailed analysis of market size & growth rate for all possible segments in the market. The Global Germanium (Ge) Evaporation Materials Industry presents a market overview, product details, classification, and market concentration. The report also provides an in-depth survey of key players in the market which is based on various competitive intelligence parameters like company profiles,…

Graphene and 2-D Materials : Angstron Materials ,Vorbeck Materials ,Applied Grap …

Global Workforce Management Software Market reports provide CAGR Value 2018-2025 and in-depth analysis of Top Players, Geography, End users, Applications, Competitor analysis, Sales, Revenue, Price, Gross Margin, Market Share, Trends and Forecast.

Workforce Management Software Market Report provides a basic overview of the industry including definitions, classifications, applications and industry chain structure. The Workforce Management Software market analysis is provided for the international markets including development trends, competitive landscape analysis, and…

Graphene and 2-D Materials Market Analysis Report By Key Players- XG Science, An …

UpMarketResearch offers a latest published report on “Global Graphene and 2-D Materials Market Industry Analysis and Forecast 2018-2025” delivering key insights and providing a competitive advantage to clients through a detailed report. The report contains 113 pages which highly exhibits on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability.

Get Free Sample Report@ https://www.upmarketresearch.com/home/requested_sample/6411

The report begins with the overview of the Graphene…