Press release

Controlled Intelligent Packaging Market Progresses for Huge Profits During 2017 – 2027

The controlled intelligent packaging is defined as a packaging system that helps to carry out intelligent functions, for example, detect and applying logical rationale to encourage primary detecting, recording, sensing, communicating land helps to take decision of extending shelf life, enhance safety, helps in improving quality, provide information and warn about possible problems. The controlled intelligent packaging is utilized to communicate with the consumer as a tool for marketing, protect the item against the deteriorative impacts of the external condition, contain the product of different sizes and shapes and give the consumer with greater usability and efficient comfort. The controlled intelligent packaging has a broad range of application in various industries such as Food and beverage, cosmetics, pharmaceutical industries.Request For TOC @ https://www.futuremarketinsights.com/toc/rep-gb-4133

Global Controlled intelligent packaging: Market Dynamics:

Food and beverage industry mainly drive the global controlled intelligent packaging market. The consumer prefers an increase in demand for safe and healthy food due to which controlled intelligent market is growing. Nowadays, consumers are more inclined towards ready to eat packaged food which leads to a growth of controlled intelligent packaging market. Moreover, the global controlled intelligent packaging helps to protect food from contamination and chemical. Controlled intelligent packaging helps to increase the lifespan of the food. Owing to changing consumer preference, high-quality food products, Increase in demand for quality food products further leads to the rise in demand for controlled intelligent packaging market. Macroeconomic factors such as a societal status change in lifestyle, a rapid increase in urbanization rate, technological advancements further leads to the growth of global controlled intelligent packaging market. The need to raise consistence and adherence levels will support in compliance with monitoring devices and active and items. However, moderately high expenses and healthcare industry cost control issues across the board use. The increased prevalence of drugs with increase moisture sensitivity will lead to boost the controlled intelligent packaging market.

Global Controlled intelligent packaging: Market segmentation:

The global controlled intelligent packaging market is segmented on the basis of applications, product type, and end-use industry:

Based on applications, global controlled intelligent packaging market is segmented into:

Pack integrity

Safety and quality standards

Traceability

Product authenticity

Based on indicators, global controlled intelligent packaging market is segmented into:

Time-temperature indicators

Freshness indicators

Integrity Indicators

Based on sensor types, global controlled intelligent packaging market is segmented into:

Gas sensors

Biosensors

Fluorescence based oxygen sensors

Based on product types, global controlled intelligent packaging market is segmented into:

Pouch

Container

Drum

Pallet

Based on end use industry, global controlled intelligent packaging market is segmented into:

Food and Beverage Industry

Seafood

Meat and poultry

Soup

Dairy products

Confectionaries

Fruits and vegetables

Pharmaceutical Industry

Cosmetics Industry

Global Controlled intelligent packaging: Regional Outlook:

Based on geographic region global controlled intelligent packaging market is segmented into seven regions includes North America, Latin America, Japan, Eastern Europe, Western Europe, Asia-Pacific excluding Japan and the Middle East and Africa. North America and Western Europe holds the largest share in the global controlled intelligent packaging market owing to a large number of convenience stores and ready to eat food products followed by Japan, and Latin America. In North America and Europe, strict regulations surrounding the utilization of active packaging have been empowering the usage of controlled intelligent packaging. Asia-Pacific and the Middle East and Africa leads to a growth of global controlled intelligent packaging market in the forecasted period due to rise in food and beverage industry and increase in demand for packaged food.

Request For Sample @https://www.futuremarketinsights.com/reports/sample/rep-gb-4133

Global Controlled intelligent packaging Players:

The few prominent key players of the global controlled intelligent packaging market are:

Cargill Inc.

Archer Daniels Midland Co

BASF SE

Celanese Corp.

Kerry Group

EastmanChemical Co.

International Paper Co.

Tetra Pak

DuPont

Ball Corp.

Crown Holdings Inc.

Bemis Company Inc.

Nestle

Tyson Foods Inc.

Kraft-Heinz Co.

STERIS

Honeywell International Inc.

ABOUT US:

Future Market Insights (FMI) is a leading market intelligence and consulting firm. We deliver syndicated research reports, custom research reports and consulting services, which are personalized in nature.

FMI delivers a complete packaged solution, which combines current market intelligence, statistical anecdotes, technology inputs, valuable growth insights, an aerial view of the competitive framework, and future market trends.

CONTACT:

Future Market Insights

616 Corporate Way, Suite 2-9018,

Valley Cottage, NY 10989,

United States

T: +1-347-918-3531

F: +1-845-579-5705

Email: sales@futuremarketinsights.com

Website: http://www.futuremarketinsights.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Controlled Intelligent Packaging Market Progresses for Huge Profits During 2017 – 2027 here

News-ID: 1016901 • Views: …

More Releases from Future Market Insights

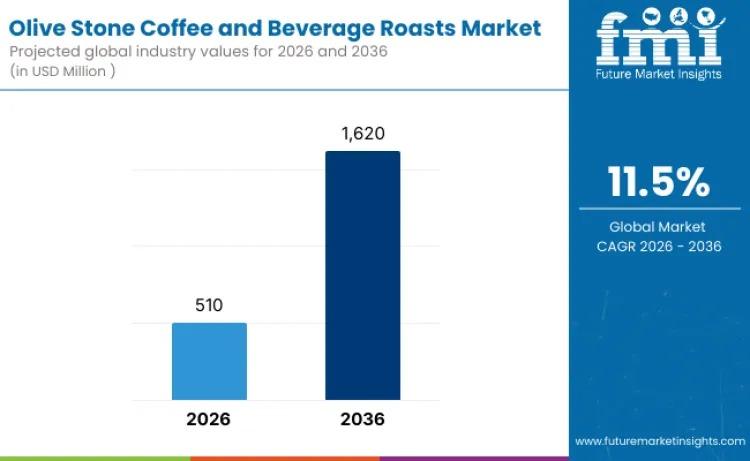

Global Olive Stone Coffee and Beverage Roasts Market to Reach USD 1,620 Million …

The global olive stone coffee and beverage roasts market is entering a high-growth decade, fueled by sustainability innovation and evolving specialty coffee culture. Valued at USD 510 million in 2026, the market is projected to reach USD 1,620 million by 2036, expanding at a compelling CAGR of 11.5%.

As consumers increasingly seek beverages that combine sustainability, functionality, and distinctive taste, olive stone-based roasting solutions are transitioning from niche experimentation to structured…

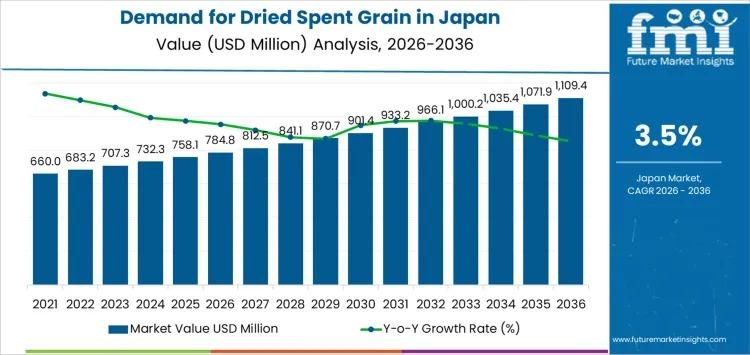

Japan Dried Spent Grain Market to Surpass USD 1.1 Billion by 2036 as Feed Optimi …

Japan's dried spent grain market is entering a decade of steady, value-driven expansion, supported by structured feed demand, brewery byproduct utilization, and rising integration of fiber-rich ingredients into food manufacturing. Industry estimates place the market at USD 784.8 million in 2026, with projections indicating growth to USD 1,109.4 million by 2036, reflecting a CAGR of 3.5%.

Between 2020 and 2026, demand increased from USD 637.5 million to USD 784.8 million, shaped…

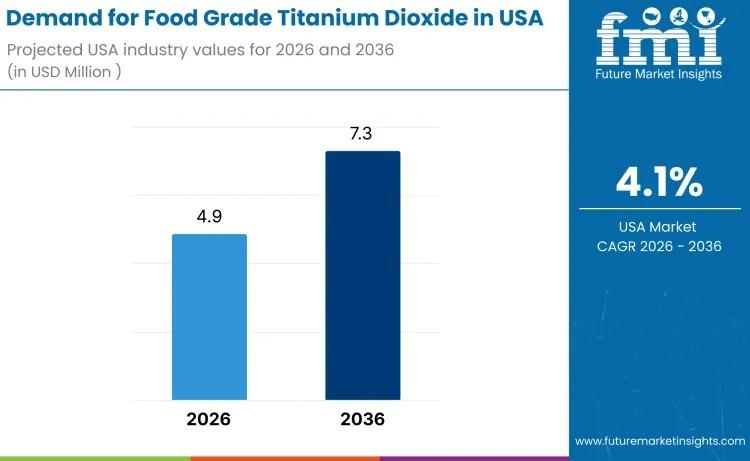

USA Food Grade Titanium Dioxide Market to Reach USD 7.3 Million by 2036 Amid Ste …

The demand for food grade titanium dioxide in the USA is valued at USD 4.9 million in 2026 and is projected to reach USD 7.3 million by 2036, expanding at a CAGR of 4.1%. Growth remains moderate yet stable, supported by continued use of titanium dioxide as a whitening and opacifying agent across confectionery coatings, bakery decorations, sauces, dairy analogues, and processed food matrices.

Despite heightened regulatory scrutiny and evolving clean-label…

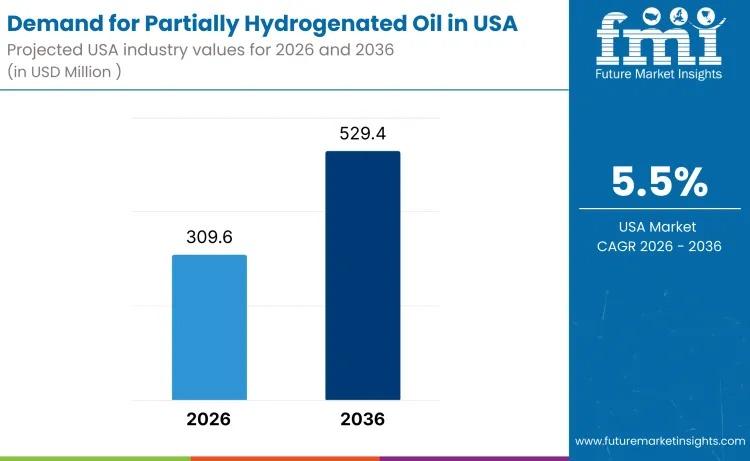

USA Partially Hydrogenated Oil Market to Reach USD 529.4 Million by 2036 Amid Me …

The demand for partially hydrogenated oil in the USA is projected to rise from USD 309.6 million in 2026 to USD 529.4 million by 2036, expanding at a steady CAGR of 5.5%. While edible applications remain tightly regulated, demand persists across specialty industrial and permitted food-related segments where oxidative stability, viscosity control, and texture performance remain critical.

Despite regulatory constraints on trans fats in conventional food manufacturing, PHOs continue to serve…

More Releases for Controlled

Automotive Silicon-Controlled Rectifier Market

Automotive Silicon-Controlled Rectifier Market Overview

Featuring immunity to surges and transients in static states and commutations, our silicon-controlled rectifiers (SCR), also known as thyristors, are ideal for single- and three-phase power line networks, even in harsh environments up to 150°C. In addition to AC, DC and capacitive ignitor circuits, these unidirectional switches are found in high-voltage industrial circuits as well as automotive equipment and all other segments where electromechanical relays are…

Passive Temperature Controlled Packaging Market 2023-2032: Temperature-Controlle …

In a world where the pharmaceutical industry is experiencing unprecedented growth due to an expanding global population, particularly the elderly, and a rising number of communicable and non-communicable diseases, the demand for both prescription and non-prescription drugs has never been higher. This surge in critical pharmaceutical needs has become a driving force behind the remarkable growth of the global passive temperature-controlled packaging market.

Allied Market Research has recently unveiled a…

Controlled Atmosphere Storage Using a DataTaker

DT80 Provides Single Solution & Saves Money

A company contacted CAS DataLoggers with a controlled atmosphere storage environment project as part of pilot testing for a new process. To reduce costs, existing equipment was used wherever possible. The hostile atmosphere produced was found to be incompatible with available humidity sensor technologies, requiring these measurements to be derived in real time using measurements from secondary sensors. The price of logging different sensors…

Temperature Controlled Packaging Systems Market

This report presents the worldwide Temperature Controlled Packaging Systems market size (value, production and consumption), splits the breakdown (data status 2013-2018 and forecast to 2025), by manufacturers, region, type and application. This study also analyzes the market status, market share, growth rate, future trends, market drivers, opportunities and challenges, risks and entry barriers, sales channels, distributors and Porter’s Five Forces Analysis.

Download FREE Sample of this Report @ https://www.grandresearchstore.com/report-sample/global-temperature-controlled-packaging-systems-2025-971

The Temperature Controlled…

Controlled Drug Delivery Market Controlled Drug Delivery Clinical Pipeline Repor …

For Report Sample Contact: neeraj@kuickresearch.com or +91-11-47067990

Report Table of Contents

1 Drug Delivery: An Advancing Trajectory

1.1 Preface Towards Drug Delivery

1.2 Idealism of Drug Delivery System

2. Introduction to Controlled Drug Delivery

2.1 Novel Drug Delivery Systems

2.2 Preamble to Controlled Drug Delivery

3. Evolution of Controlled Drug Delivery

3.1 First Generation

3.2 Second Generation

4. Fundamentals of Controlled Drug Delivery

4.1 Prerequisites…

Global Controlled Drug Delivery Market & Controlled Drug Delivery Clinical Trial …

With significant paradigm shifts in drug discovery and development, the industry is also gearing up to adopt alternative drug delivery strategies in order to further facilitate drug development. Opportunities have significantly increased in the last few years. Pharmaceutical companies are collaborating with drug delivery firms to effectively target patient concerns. Many different drug delivery systems have been designed and evaluated, and a large number of strategies for site-specific drug targeting…