Press release

Development and Mold Construction Company for Prototype- and Small-Volume Production participates for the first time at AIRTEC Fair, Frankfurt

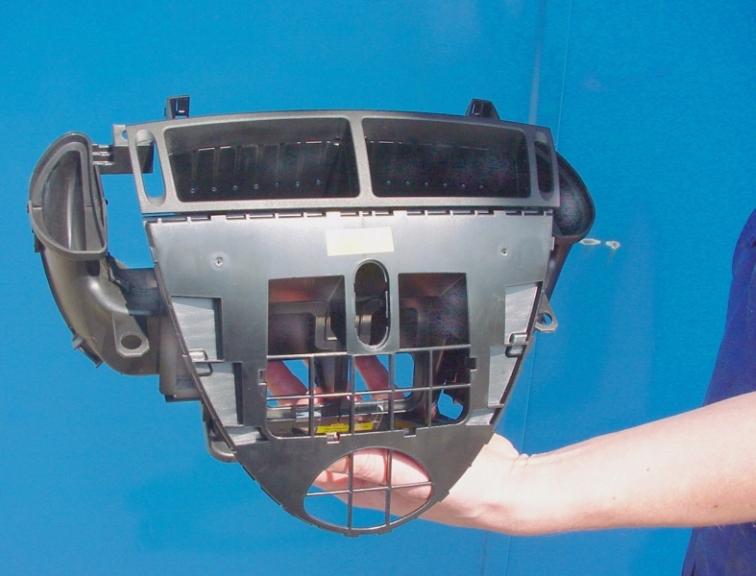

SPM mold for small batches of up to 5,000 units. Based on the Space Puzzle Molding technique, an SPM mold could be used to produce 5,000 parts for testing and marketing purposes and integrated into and used for first-off series production

Protoform K. Hofmann GmbH, Fuerth, a development and production company with a staff of 100 in development and design, mold construction and plastics injection molding, supplies prototypes and series of ready-to-fit original components in marketable and market-conforming quantities of up to 5,000 parts.

The company develops and produces plastics components and assembly groups as prototypes and in small quantities, in the same material as in mass production in „Made in Germany“ quality based on the patented “Space Puzzle Molding" technique.

Due to its network of partners, the development company Protoform K. Hofmann GmbH is able to offer a complete process chain with services ranging from product ideas over CAD design and prototype production to ready-to-fit and marketable small batches, mold construction and series production for plastics and hybrid plastics parts.

In Europe, exclusively Protoform K. Hofmann GmbH offers the Space Puzzle Molding (SPM) process for faster product development. The Space Puzzle Molding (SPM) process is a combined rapid tooling (RT) and rapid prototyping (RPT) technique which owing to optimised CAD design is able offer simplified aluminium molds at a favourable price extremely fast. Consequently, prototype series and small batches of plastics components up to several thousand pieces can be produced in original plastics material at short notice, in mass-produced component quality, within the framework of semi-automatic individual production on normal injection molding machines.

The Space Puzzle Molding (SPM) process enables the production of reasonably priced testing series and pre-series of series-identical plastics parts made of original material and marketable small batches in quantities of several thousand units for first-off series production. The produced parts can be used for testing and marketing purposes and integrated into and used for first-off series production.

With the SPM technique and its in-house mold construction, Protoform K. Hofmann GmbH can cover the whole plastics product development process chain from development and design, prototype series and small batch production of components with series-identical material and in mass-produced quality in units of up to 5,000 pieces in all areas of industry. The Space Puzzle Molding (SPM) process is primarily used in automotive, above all by reputable European automobile manufacturers and their suppliers. Leading automobile manufacturers recommend using the SPM process for product development and first-off series production.

Further press material:

At request, various practical technical reports with photos and illustration are available for the trade press, editors and trade journalists in Word format/JPEG, 300 dpi, for press and publication purposes.

A technical SPM process documentation is available as a PDF file (in German, English and French) and sent by e-mail. Furthermore an technical documentation "Small-volume production with the Space Puzzle Molding (SPM) Process” which contains a description of six (6) development projects with subsequent small-volume production (PDF file, sent by e-mail).

Various practical reports (4 pages, German, English) are available in special print edition, also in PDF file format and by e-mail. In these reports, the SPM process is described in general as well as in practical use, i. a. in automotive and medical engineering industries.

Protoform® K. Hofmann GmbH, D 90766 Fuerth/Bavaria:

Protoform K. Hofmann GmbH, a Bavaria-based company that employs a staff of approx. 100, has been active in the field of CAD design, CAM programming, tool and mold construction and plastics injection molding based on the patented Space Puzzle Molding (SPM) process for many years. Protoform specialises exclusively in the SPM process and has optimised the technique, launched more than twenty (20) years ago, to its current efficient state.

Protoform has gathered experience with mold and prototype production, based on a 30-year mold making tradition, and uses the patented Space Puzzle Molding® (SPM) process invented by Konrad Hofmann for manufacturing in Fuerth/Bavaria on a total production and manufacturing floor space of 2,800 square meters.

The company has a customised machine pool for mold manufacture, high-speed processing production techniques, CAD design and organisation as well as injection-molding component production designed for SPM. Protoform's mold building focuses exclusively on the production of SPM molds: The customised machine pool enables factory-like, rapid production throughput of SPM molds with up to 50 percent shorter time-to-market than conventional molds. A state-of-the-art machine pool is used for highly automated production.

The Space Puzzle Molding (SPM) process has been used successfully for more than twenty (20) years. It delivers plastic and projects for hybrid plastic components made of original material in mass-produced quality. More than 8,000 plastic components, plastic products and complete assembly groups have been handled so far and produced in small batches of up to 3,000 marketable components. Normally, quantities of up to 5,000 units with a shot weight of up to 2,200 grams can be achieved with the SPM process.

From a technical point of view, the SPM process enables all conventional production techniques like gas assist molding, multi-component injection molding, insert and outsert technique and in-mold decoration (IMD). The process can be used to produce whole cockpit assembly groups and individual components with the maximum dimensions 400 x 600 x 800 millimetres.

The company’s main customers are development departments in the automotive and commercial vehicle industry, their suppliers, departments in the electrical engineering and electronics, equipment industry, general apparatus construction and medical engineering.

With the SPM technique and its in-house mold construction, Protoform® K. Hofmann GmbH can cover the whole plastics product development process chain from development and design, prototype series and small batch production of components with series-identical material and in mass-produced quality in units of up to 5,000 pieces in all areas of industry. Leading automobile manufacturers recommend using the SPM process for product development and first-off series production. Protoform has been certified by the automotive industry association VDA, according to quality standards VDA 6.4 and DIN EN ISO 9001.

Protoform has a network of competent, selected and efficient specialist partners and mold makers with injection molders for subsequently moving up from prototype and small-volume production to large-volume production.

Protoform K. Hofmann GmbH

Siemensstrasse 45

90766 Fuerth / Germany

Tel.: 0049 911 7599-0

Fax: 0049 911 7599-100

Internet: www.protoform.com

E-mail: info@protoform.com

Press Contact:

Wolfgang G. Trapp

Pressebüro

Postfach 65 00 73

D 81214 Munich

Telefon: (089) 811-7414

eMail: trappresse@aol.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Development and Mold Construction Company for Prototype- and Small-Volume Production participates for the first time at AIRTEC Fair, Frankfurt here

News-ID: 9885 • Views: …

More Releases for SPM

Leading SPM Machine Manufacturer Redefines Precision Engineering

eb2bmart a trusted name in industrial automation, proudly announces its latest advancements in Special Purpose Machines (SPM), delivering unmatched precision, productivity, and reliability for diverse manufacturing industries.

As a premier SPM machine manufacturer, [Company Name] specializes in designing and building tailor-made machines that meet the exact requirements of clients across automotive, aerospace, electronics, and heavy engineering sectors. With a focus on innovation and customer satisfaction, the company integrates cutting-edge technology and…

Global SPM Cleaning System Industry Outlook Analysis 2025-2031

According to our (Global Info Research) latest study, the global SPM Cleaning System market size was valued at US$ 289 million in 2024 and is forecast to a readjusted size of USD 406 million by 2031 with a CAGR of 5.0% during review period.

SPM cleaning system is a professional cleaning equipment with efficient and precise corrosion cleaning functions. It can perform detailed treatment on various surfaces to ensure that the…

SAP | Service Providers | SPM Global Technologies

The success of any organization relies on powerful communication and data exchange among its functions, and SAP is an efficient way to boost those efforts.

SPM Global Technologies is a trusted SAP Partner

In this day and age, digital transformation is helping various organizations to stay relevant in their industry and drive business growth. SPM Global Technologies is helping such organizations to realize their digital transformation with SAP.

With its deep association with…

Scanning Probe Microscopes (Spm) Market News 2022 to 2032

The Scanning Probe Microscopes (SPM) market refers to the market for instruments used for high-resolution imaging and measurement at the nanoscale level. SPMs are widely used in various scientific research fields, including nanotechnology, materials science, life sciences, and semiconductor industries.

Our Free Sample Report - Download Now: https://marketdatalibrary.com/contact-us

Scanning Probe Microscopes (Spm) Market Challenges:

-Limitations in imaging speed and resolution: SPMs are known for their ability to provide high-resolution images at the atomic…

Global Scanning Probe Microscopes (SPM) Market Progress Research 2018-2025

Research Report 2018-2025 on "Global Scanning Probe Microscopes (SPM) Market" which provides an outlook of current market value of Scanning Probe Microscopes (SPM) Market as well as the expected forecast of Rate on Investment (ROI) with growing CAGR of XX% in Scanning Probe Microscopes (SPM) Market by the end of 2025. The report on the global Scanning Probe Microscopes (SPM) market uses the top-down and bottom-up approaches to define, analyze,…

Scanning Probe Microscopes (SPM) Market: Latest Trends and Insights 2024

Scanning probe microscopes include imaging technologies that measure surface of small molecules, atoms and fine scales. This technique uses interaction of sharp, electrically charged probe with the surface of samples at particular points. This electrically charged probe is used to interact with sample that helps researchers to understand the properties of sample specimen. In addition, scanning probe microscope scan sample surface with sharp probe in order to observe three dimensional…