Press release

Silicone-based Release Coatings Market : Industry Insights With Key Company Profiles

Coating is either a film or covering applied on the surface of an object, generally referred to as ‘substrate’. A release agent is a chemical used to prevent other materials/carriers from bonding to surfaces/substrates, providing a critical barrier between them. Release coating is a film, which is coated on one or two sides with a release agent, offering a release effect against an adhesive. Silicone, referred to as polysiloxanes, is a polymer having alternate links of silicon and oxygen atoms. Silicone-based release coatings imply silicone as a releasing agent between two potentially interacting substrates. Such release coatings are often used as back side coatings for paper products or films for various cohesive and pressure sensitive adhesive applications. The function of these coatings is to alter surface properties such as adhesion, wettability, corrosion resistance, and wear resistance of substrates.The global silicone-based release coatings market is primarily driven by the increase in demand in food and bakery, hygiene, and medical industries. Increase in consumption of UV silicone release coatings is expected to fuel the market. UV silicone release coatings based on cationic cure and radical cure operate at lower temperatures on temperature-sensitive films, unlike conventional silicone-based release coatings. Silicone compounds embedded in the release coatings can act both as release agents and as pressure sensitive adhesives. They are widely utilized in the manufacturing industry for interleaving applications, roofing (bitumen), insulation tapes, self-adhesive stamps, and composites. Rising demand from manufacturing industries is anticipated to boost the silicone-based release coatings market. Furthermore, increase in per capita income and rise in awareness about healthcare are boosting the silicone-based release coatings market in developing economies. Development and manufacture of polydimethylsiloxane (PDMS)-based release coatings is expected to provide lucrative opportunities to the silicone-based release coatings market. However, high degree of customization required for varied applications is likely to hamper the silicone-based release coatings market.

Browse Research Report With Complete TOC @ https://www.transparencymarketresearch.com/siliconebased-release-coatings-market.html

In terms of formulation, the silicone-based release coatings market can be divided into solvent-based, water-based, and oil emulsion. Solvent-based coatings provide good anchorage for applications such as pressure sensitive label stock, industrial single-sided release papers, and nonstick food-grade packaging. They are applicable for films and hard-surfaced papers. Water-based release coatings are employed in a broad range of applications in food and baking, tapes, and industrial sectors. Oil emulsion-based release coatings possess long bath life, good shear stability, and low foaming potential. Thus, they are suitable for premium release performances and size press operations.

Based on application, the silicone-based release coatings market can be segmented into labels, tapes, envelopes, and others. The labels segment holds a significant share in the silicone-based release coatings market due to their attributes such as low surface tension and low surface energy. These release coatings enable easy delamination or easy label transfer from the liners onto the object to be labeled. Silicone-based release coatings possess the property of reproducing releasing force, therefore, the tapes segment holds a significant share in the silicone-based release coatings market. Silicone-based release coating tapes have wide applications in the manufacturing industry owing to their rheological characteristics and diverse structures.

In terms of end-use industry, the silicone-based release coatings market can be segmented into food & bakery, hygiene, manufacturing, medical, and others. Several properties of silicone-based release coatings include wetting, foaming, cure speed, bath life, release, coverage, wear resistance, and shear stability. These properties are favorable for baking, food packaging, and other industrial applications. Demand for silicone-based release coatings has been rising, due to the approval of the U.S. Food and Drug Administration (FDA) and Canadian Food Inspection Agency (CFIA). The food & bakery segment accounts for a key share of the silicone-based release coatings market.

Request a PDF Brochure with Research Report Analysis @ https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=35501

Based on geography, the silicone-based release coatings market can be segregated into North America, Latin America, Asia Pacific, Europe, and Middle East & Africa. The market in Asia Pacific is anticipated to expand rapidly due to prompt expansion in consumption of solvent-less silicone-based release coatings in countries such as China, Japan, Korea, and Taiwan. North America and Europe hold significant share on account of growing awareness in terms of health and environment.

Key players operating in the global silicone-based release coatings market include Dow Corning Corporation, Wacker Chemie AG, Evonik Industries AG, Momentive Performance Materials Inc., OMNOVA Solutions Inc., and Rayven, Inc.

About Us

Transparency Market Research (TMR) is a market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. TMR’s experienced team of analysts, researchers, and consultants, use proprietary data sources and various tools and techniques to gather, and analyze information. Our business offerings represent the latest and the most reliable information indispensable for businesses to sustain a competitive edge.

Each TMR syndicated research report covers a different sector - such as pharmaceuticals, chemicals, energy, food & beverages, semiconductors, med-devices, consumer goods and technology. These reports provide in-depth analysis and deep segmentation to possible micro levels. With wider scope and stratified research methodology, TMR’s syndicated reports strive to provide clients to serve their overall research requirement.

US Office Contact

90 State Street, Suite 700

Albany, NY 12207

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Email: sales@transparencymarketresearch.com

Website: https://www.transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Silicone-based Release Coatings Market : Industry Insights With Key Company Profiles here

News-ID: 973194 • Views: …

More Releases from Transparency Market Research

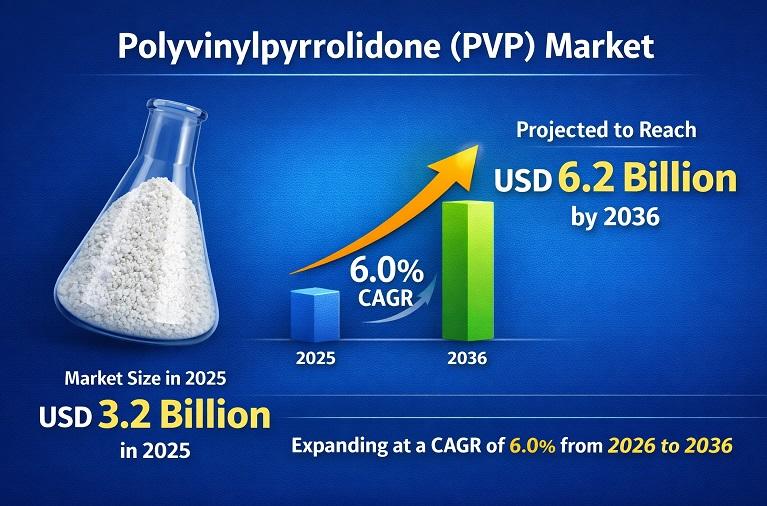

Polyvinylpyrrolidone (PVP) Market to Reach USD 6.2 Billion by 2036 Driven by Pha …

The Polyvinylpyrrolidone (PVP) Market was valued at around US$ 3.2 billion in 2025 and is projected to reach approximately US$ 6.2 billion by 2036, expanding at a steady CAGR of about 6.0% during the forecast period. This growth is primarily driven by rising demand from the pharmaceutical industry, where PVP is widely used as a tablet binder, solubilizer, and stabilizer, along with increasing consumption in cosmetics and personal care products…

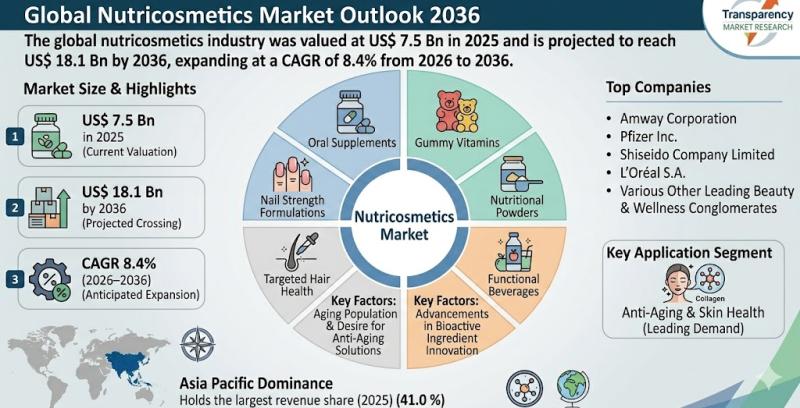

Nutricosmetics Market to Reach US$ 18.1 Bn by 2036, Expanding at 8.4% CAGR Drive …

The global nutricosmetics market was valued at US$ 7.5 Bn in 2025 and is projected to reach US$ 18.1 Bn by 2036, expanding at a robust CAGR of 8.4% from 2026 to 2036. Nutricosmetics-nutritional supplements and functional products designed to enhance skin, hair, and nail health from within-are gaining substantial traction worldwide. The growing consumer shift toward holistic wellness, preventive healthcare, and clean-label beauty solutions is significantly driving market expansion.

Nutricosmetics…

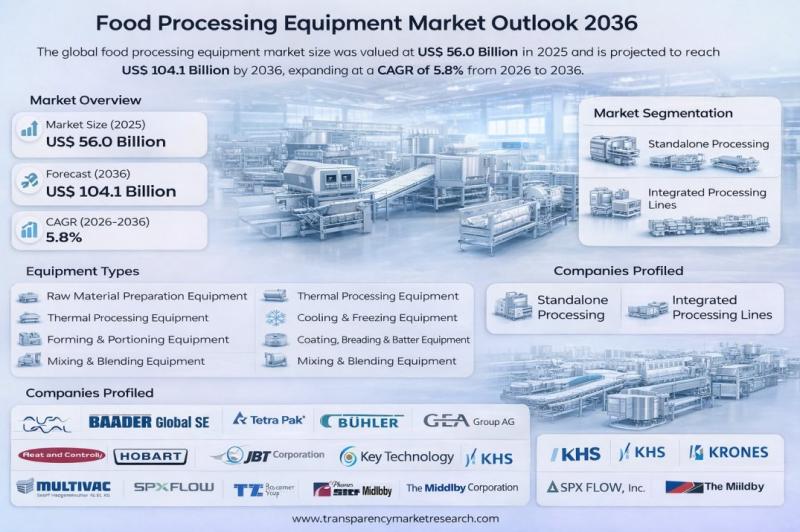

Food Processing Equipment Market to Reach US$ 104.1 Billion by 2036, Driven by A …

The global food processing equipment market was valued at US$ 56.0 Billion in 2025 and is projected to reach US$ 104.1 Billion by 2036, expanding at a CAGR of 5.8% from 2026 to 2036. Market expansion is being driven by rising demand for processed and convenience foods, expanding urbanization, increasing automation in food manufacturing, stringent food safety regulations, growing meat and dairy consumption, technological advancements, adoption of energy-efficient machinery, industrialization…

Global Household Cooking Appliances Market to Reach USD 160.3 Billion by 2036, D …

The global household cooking appliances market is poised for robust growth over the next decade. Valued at US$ 88.3 billion in 2025, the market is projected to reach US$ 160.3 billion by 2036, expanding at a steady CAGR of 5.5% from 2026 to 2036. The market outlook remains highly positive as rapid urbanization, rising disposable incomes, and evolving consumer lifestyles continue to reshape global kitchen environments.

Household cooking appliances include gas-…

More Releases for Silicone

Revolutionizing Industries: Tenchy Silicone Introduces Cutting-Edge Silicone Tub …

Shenzhen Tenchy Silicone And Rubber Co., Ltd, a renowned leader in silicone products manufacturing, proudly announces the launch of its advanced silicone tubing solutions. Designed to meet the diverse needs of industries such as medical, automotive, and food and beverage, these innovative products represent a significant step forward in silicone technology.

In a world where reliability, performance, and versatility are paramount, silicone tubing stands out as a material of choice for…

Five common properties of silicone and the primary Types of Silicone

Silicones are a versatile class of polymers that come in various forms, offering immense potential for customization to meet the precise needs of the medical and aerospace sectors. Their characteristics enable them to perform diverse functions, such as sealing, lubricating, and fulfilling a host of other tasks.

Silicone's versatility is attributed to its unique physical and mechanical properties, which make it a valuable material in various industries. This article will delve…

Tenchy Silicone: Quality Silicone Tube Supplier for Different Industries

Tenchy Silicone is proud to announce the opening of their new headquarters, which will provide a quality silicone tube supplier service to different industries and businesses. Their silicone tubes are made from FDA-approved materials and are temperature resistant up to 230 degrees Celsius. All products come with an assurance of quality from Tenchy Silicone's team of experienced engineers and technicians who ensure that each product meets customer needs and specifications.…

Tenchy Silicone introducing new silicone foam strip

Tenchy Silicone, the leading provider of high-quality silicone foam strip, is proud to announce their newest product. The Silicone Foam Strip features a combination of both closed-cell and open-cell foaming technologies which offers outstanding thermal insulation and water resistance properties as well as superior airtight performance. It also provides excellent cushioning for equipment, machinery, components and instruments to ensure protection from dust, moisture, abrasion and shock. In addition to its…

Tenchy Silicone Announces Expansion on Silicone Tube Supplier Selection

Tenchy Silicone, a leading silicone tube supplier, is pleased to announce the expansion of its selection of products and services for customers. With over ten years of experience in the industry, the company has established a reputation for providing top-quality silicone tubes that meet customer needs and expectations. The new product line includes tubing from various manufacturers and offers a wide range of materials and sizes to accommodate every project.…

Tenchy Silicone Unveils their New Silicone Seal Gasket

Tenchy Silicone recently released a new silicone seal gasket designed to be used in a variety of industrial applications. It also provides excellent temperature insulation thanks to its ability to withstand temperatures up to 260 °C without any deformation or loss of strength, making it ideal for large-scale industrial projects. The silicone seal gasket is also unaffected by chemicals and ultraviolet light, making it suitable for numerous industries including automotive,…