Press release

SOIL CONSERVATION WITH SWISS WOOD WOOL (Erosioncontrol)

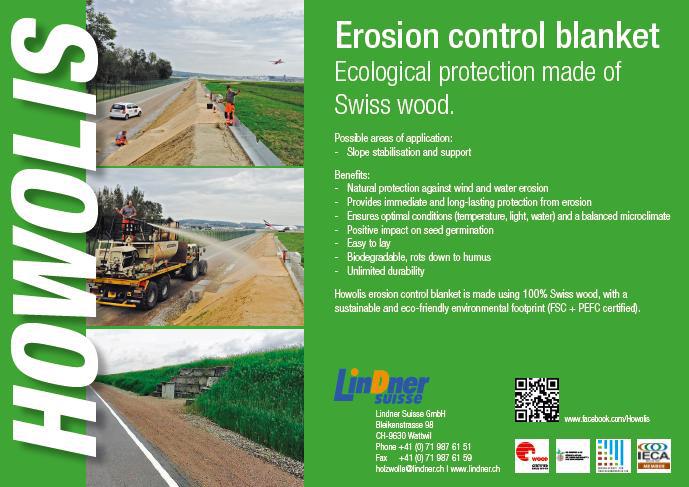

The Swiss company Linder Suisse from Wattwil has been successfully manufacturing erosion control fleece made of wood wool for several years. This ecologically sound method of slope stabilization has already proven itself in numerous projects.What do a teddy bear, an Easter nest and a steep slope at the edge of a Toggenburg forest have in common? The businessman Thomas Wildberger solves the mystery: The link is wood wool, he explains. It provides the filling that puts teddy bears into shape, acts as decoration for Easter nests and - made into erosion control matting - ensures the stability of the steep slope. Since 1996, Wildberger has been at the head of Lindner Suisse, a Wattwil-based company with a history going back almost 100 years, the only wood wool manufacturer in Switzerland. He is constantly launching new innovations and testifying to this versatile material with great potential for the future. One of his most recent projects is the production of “Howolis” erosion control matting. Comparable products have been in use in the US for decades and have proven their worth. What works there will also work in Switzerland, Wildberger thought, and had a machine developed to produce the wood fabric. It produces a geotextile from loose wood wool that is meshed into a fabric made from jute or biodegradable plastic. It is intended to help protect slopes from erosion and to permanently replant them through seeding. The wood wool used is made from FSC and PEFC certified timber from the region (PEFC = Programme for Endorsement of Forest Certification). The formulation of each wood wool mixture depends on the area in which it is to be used and is produced from A or B class wood, including pine, fir or beech. Thomas Wildberger explains: “With this, I am putting a sustainable Swiss product on the market that presents an alternative to imported natural fibre matting”. Wildberger is confident that the application will work because the success seen in the US speaks for itself. There were similar investigations in Switzerland in the 1990s at ETH (ETH Zurich is one of the world’s leading universities for technology and the natural sciences) into using comparable erosion production methods in the Alpine region. Now the task is to make the product known in Switzerland and Europe.

Passed the field test

Last autumn, Lindner Suisse initiated field testing on a slope adjoining the company’s premises. Shortly before the onset of winter, the open soil was seeded and various types of wood wool matting were fixed on it for test purposes. This spring it became apparent that the growth of grass through the matting is making good progress and and blades are slowly but surely taking over the mesh. As part of a broad study, Lindner is currently coordinating a larger erosion control project in Wattwil, which is being supported by the Federal Office for the Environment (FOEN) and St. Gallen Agricultural Office. A soil protection firm from eastern Switzerland and a local construction company are also involved. Wildberger deliberately seeks dialogue with proven experts from various disciplines: “I am happy to bring people from different industries together for a specific project. This enables resources to be pooled and combined”. He reveals his enthusiasm when he talks about the current field testing on a steep slope in Wattwil in which “Howolis” erosion control matting is to be put to the ultimate test. Pre-manufactured beechwood rods with a laterally inserted wooden dowel at the top are used to attach the matting to the soil. Deployed in various thicknesses depending on the project in question, the wood wool mesh creates the ideal microclimate for the seed.

A large number of production steps

The way from tree trunk to wood wool and to erosion control matting involves numerous work stages. The company’s capital is piled up on the spacious gravel yard behind the factory building in the form of logs several metres in length. This is where the peeled tree trunks are stored and air-seasoned for months on end prior to further processing. The production process requires a lot of manual work. For high-quality wood wool, the raw material has to be presorted manually. Then it is cut into 50 cm sections. Production is currently in full swing. There is a droning in the air, the dust is flying, the flywheels of the machines are spinning rhythmically, the horizontal blade carriages move back and forth at high speed and plane the solid round timber into wood fibres in no time. It is, says Wildberger, a common fallacy that wood wool is a residual or waste product of the wood processing industry. On the contrary, it is a high-quality product that deserves to become more well known again. Wood wool was once a popular material that had fallen into disuse following the introduction of plastic.

Further products

The newly developed machine opens up a great number of new perspectives for Lindner Suisse. Wood wool matting is not only suitable for deployment in the battle against erosion but similarly offers solutions for hydraulic engineering, viniculture and horticulture.

Swiss wood wool

In a study supported by the “Swiss Fund for the Promotion of Forest and Wood Research”, Lindner Suisse GmbH addressed the question of to what extent Swiss wood wool fleeces are suitable for slope stabilization and erosion control. The project team demonstrated that wood wool fleeces are, at the very least, an alternative on a par with imported natural fibre fleeces such as jute. Production from local hardwood is sustainable and ensures only a small environmental footprint. Moreover, the production of wood wool fleeces provides hardwood as a resource with new sales possibilities. The findings of the study turned out to be thoroughly positive and have convinced the Federal Office for the Environment FOEN which officially approved the final report of the study.

A company steeped in tradition

Lindner Suisse, based in Wattwil in the Toggenburg region of Switzerland, has been in the wood wool business for almost 100 years. Fully-certified top-quality wood wool is produced here in 170 varieties for a large number of applications and exported to 19 countries. As the absolute specialist and expert for wood wool, Lindner develops new, innovative products on an ongoing basis. https://www.youtube.com/watch?v=KP3MHHLfv6U

Lindner Suisse Holzwollemanufaktur

Bleikenstrasse 98

9630 Wattwil

Tel +41 71 9876151

www.lindner.ch

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release SOIL CONSERVATION WITH SWISS WOOD WOOL (Erosioncontrol) here

News-ID: 956479 • Views: …