Press release

Electrically Conductive Coatings Market to Witness an Outstanding Growth By 2025

Electrically conductive coatings are coatings used to make conductive coating films. These coatings are produced using special techniques and are applied as an anti-static polymer. Electrically conductive coatings has several EMC (electromagnetic compatibility) related applications including communications equipment, PDAs, antennas and pagers, mobile phones, consumer electronics, entertainment systems TVs, cable boxes, receivers, computer equipment, monitors and laptops, medical monitors and analyzers, industrial and automated control systems, satellite systems, military and weapons systems and aerospace systems. These coatings have the ability to solve numerous electromagnetic compatibility (EMC) issues including radio-wave shielding, electromagnetic shielding, prevention of static charge and specific absorption ration protection. Plastic enclosures/housings and components must be fully or selectively coated with electrically conductive coatings as certain properties of these coatings such as interference emission can prove to be quite beneficial. Electrically conductive coatings deliver superior gloss consistency and are available in different colors as well as in textured or smooth finishes. The performance of electrical conductive coatings is determined based on their adhesion strength towards plastic materials or the specifications defined by users. Generally, evaluation methods for electrically conductive coatings include damp heat tests, heat resistance tests, salt spray tests, sheet resistance test, metal power isolation and shielding effects, etc.Request Report For TOC @

https://www.persistencemarketresearch.com/toc/15232

These days, slim and compact electrical and electronic devices are quite high in demand. Enhancing frequency distribution density of electromagnetic energy and increasing plastic usage require an effective and powerful shielding technology of electromagnetic waves. It is in this particular area that electrical conductive coatings play an important role and are gaining traction in the global market.

Electrically conductive coatings consist of raw materials like epoxy, polyurethanes, acrylics and others. Epoxy is extensively used for the formulation of electrically conductive coatings because of their high durability, and mechanical properties. Epoxy based electrically conductive coatings are light in weight and offer scratch resistance, strong adhesion, impact resistance, extreme abrasion resistance and chemical resistance. The rising demand for coating applications including the epoxy-based electrically conductive coatings in various industries such as consumer electronics, automotive, aerospace, etc. is expected to drive the global market during the forecast period. Though electrical conductivity exists in most materials at some level, it is usually enhanced by the use of thermal spray coatings. Electrically conductive thermal spray coatings used in the application of several substrates can range from composites to ceramics and polymers.

Electrically conductive coatings: Market Dynamics

Rising per capita income, rapid urbanization and rapid rate of industrialization are some of the macroeconomic factors driving the electrically conductive coatings market globally. Rising demand for electrically conductive coatings for electronic devices including laptops, tablets, mobiles, LED televisions, etc. is likely to affect the market positively.

However, emission of volatile organic compounds and strict environmental regulations are expected to hamper the growth of the electrically conductive coatings market.

In terms of geography, owing to rising demand for consumer electrical products mainly from China and India, APEJ is anticipated to dominate the market for electrically conductive coatings. Additionally, a significant deciding constriction in the global electrically conductive coatings market is raw material availability. Here, again, Asia Pacific has a significant advantage, further stimulating manufacturers to focus on the region. North America, followed by Western Europe, accounts for a significant share of the electrically conductive coatings market due to the presence of vast industrial sector in the region.

Electrically conductive coatings: Key Participants

Examples of some of the market participants identified across the value chain of global electrically conductive coatings market include:

PPG Industries Inc.

Henkel AG & Co. KGaA

Axalta Coating Systems

Akzo Nobel N.V.

Creative Materials Inc.

MG Chemicals

Fluoro Precision Coatings

Request To Sample Of Report @ https://www.persistencemarketresearch.com/samples/15232

About Us

Persistence Market Research (PMR) is a third-platform research firm. Our research model is a unique collaboration of data analytics and market research methodology to help businesses achieve optimal performance.

To support companies in overcoming complex business challenges, we follow a multi-disciplinary approach. At PMR, we unite various data streams from multi-dimensional sources. By deploying real-time data collection, big data, and customer experience analytics, we deliver business intelligence for organizations of all sizes.

Contact Us

Persistence Market Research

305 Broadway

7th Floor, New York City,

NY 10007, United States,

USA,Canada Toll Free: 800-961-0353

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Electrically Conductive Coatings Market to Witness an Outstanding Growth By 2025 here

News-ID: 930298 • Views: …

More Releases from Persistence Market Research

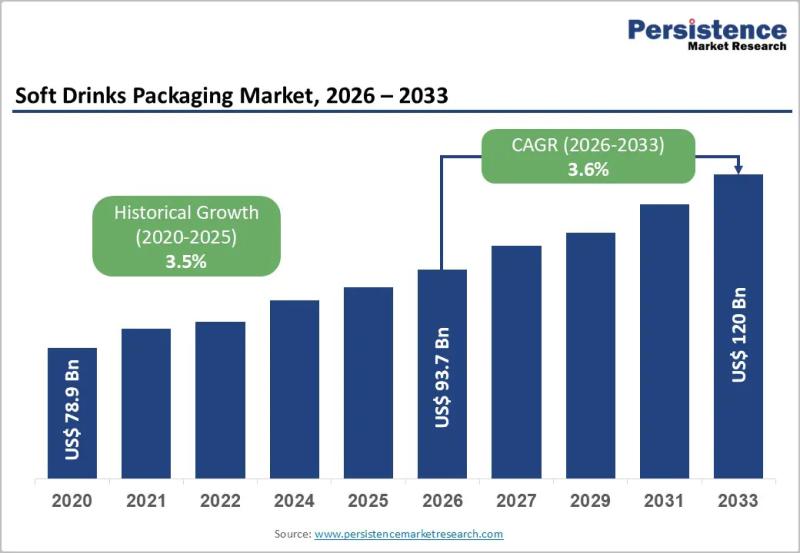

Soft Drinks Packaging Market to Reach US$120.0 Billion by 2033 - Persistence Mar …

The soft drinks packaging market plays a central role in the global beverage industry, serving carbonated drinks, juices, flavored water, energy drinks, and ready to drink teas and coffees. Packaging is no longer limited to containment and transportation; it has evolved into a critical component of branding, sustainability strategy, consumer convenience, and supply chain efficiency. Manufacturers are increasingly focusing on lightweight materials, recyclable packaging formats, and innovative designs that improve…

Christmas Tree Valves Market Size to Reach US$8.1 Billion by 2033 - Persistence …

The Christmas Tree Valves Market plays a critical role in the upstream oil and gas industry, serving as a central component in wellhead equipment systems. Christmas tree valves are installed on oil and gas wells to control pressure, regulate flow, and ensure safe extraction of hydrocarbons. These assemblies, commonly referred to as "Christmas trees," consist of multiple valves, spools, and fittings arranged in a structure that resembles a decorated tree.…

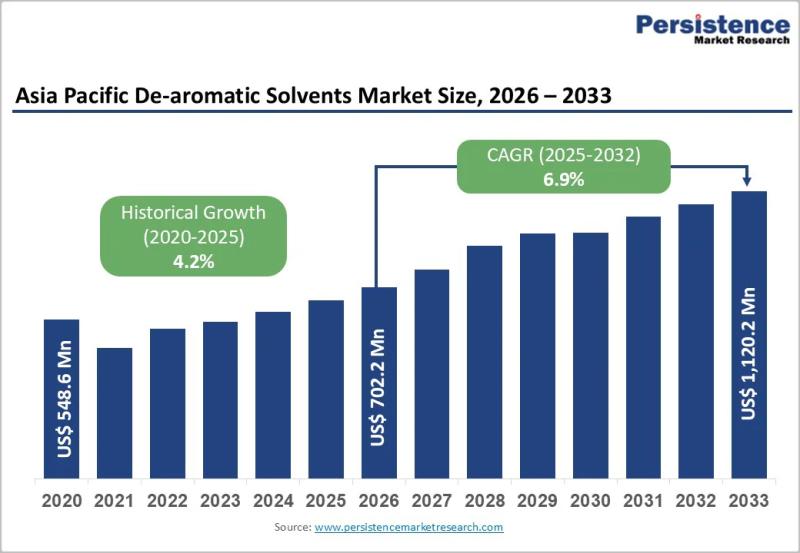

Asia Pacific De-aromatic Solvents Market to Reach US$1,120.2 Million by 2033 - P …

The Asia Pacific De-aromatic Solvents Market is gaining steady momentum as industries across the region increasingly shift toward low aromatic, high purity solvent formulations. De-aromatic solvents are hydrocarbon solvents that have significantly reduced aromatic content, making them suitable for applications requiring low odor, lower toxicity, and improved environmental performance. These solvents are widely used in paints and coatings, adhesives, inks, metalworking fluids, agrochemicals, and cleaning formulations. As regulatory scrutiny around…

Off-Highway Radiators Market to Reach US$ 7.2 Bn by 2033 as Leading Players Like …

The off-highway radiators market plays a vital role in ensuring efficient thermal management in heavy-duty equipment used across construction, agriculture, mining, and forestry sectors. These radiators regulate engine temperatures, prevent overheating, and support consistent equipment performance under extreme operating conditions. Growing mechanization and the expansion of infrastructure projects worldwide are increasing reliance on durable cooling systems. Equipment manufacturers are prioritizing high-performance radiators that offer reliability, longer service life, and resistance…

More Releases for Electrically

Electrically Operated Industrial Furnace Research:the global Electrically Operat …

QY Research Inc. (Global Market Report Research Publisher) announces the release of 2025 latest report "Electrically Operated Industrial Furnace- Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031". Based on current situation and impact historical analysis (2020-2024) and forecast calculations (2025-2031), this report provides a comprehensive analysis of the global Wire Drawing Dies market, including market size, share, demand, industry development status, and forecasts for the next few…

What's Driving Electrically Conductive Adhesives Market Trends?

Market Scenario

Global Electrically Conductive Adhesives Market was valued at US$ 1.89 Bn in 2017, and is expected to reach US$ 3.55 Bn by 2026, at a CAGR of 8.2 % during forecast period.

Global Electrically Conductive Adhesives Market

The objective of the report is to present a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, industry-validated market data and projections with a suitable set of assumptions and methodology.…

Global Electrically Trikes Market Growth 2019-2024

LP INFORMATION offers a latest published report on Electrically Trikes Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report.

According to this study, over the next five years the Electrically Trikes market will register a xx% CAGR in terms of revenue, the global market size will reach US$ xx million by 2024, from US$ xx million in 2019. In particular,…

Electrically Conductive Adhesives Market Evolving Industry Trends 2024.

Electrically conductive adhesives are used to join electronic or electrical components. These adhesives not only help complete the circuit but also maintain the conductivity of the circuit. Various types of electrically conductive adhesives include silicon based adhesives, acrylate based adhesives, epoxy based adhesives, and polyurethane based adhesives. The conductive component being used in an electrically conductive adhesive may either be graphite, silver, or copper. A synthetic resin may be used…

Electrically Conductive Coating Market Evolving Industry Trends 2024

Electrically conductive coatings are produced using special techniques. Anti-static polymer, which belongs to the family of powder polymer formulations, can be treated or coated with electrically conductive polymers in order to achieve outstanding electrical conductive properties. Coatings are applied by the electro-static method which allows proper flow and ease of use by carefully formulating the conductive material ratios, making it suitable for paint release, office automation, and chemical processes. Conductive…

Global Electrically Conductive Textiles Market Research Report 2021

MarketResearchReports.Biz presents this most up-to-date research on "Global Electrically Conductive Textiles Market Research Report 2021 "

Description

This report studies Electrically Conductive Textiles in Global market, especially in North America, Europe, China, Japan, Southeast Asia and India, focuses on top manufacturers in global market, with sales, price, revenue and market share for each manufacturer, covering

Buhler

Nanogate

Nanophase Technologies Corporation

AdMat Innovations

Surfix

Nanomech

CIMA Nanotech

P2I Ltd

Nanovere Technologies

Integran Technologies

Nanofilm

Market Segment by Regions, this report splits Global into several key…