Press release

Aluminum Casting Market Report Offers Intelligence and Forecast till 2017 - 2025

Being a light weight metal, aluminum offers excellent strength, high electrical conductivity, exceptional corrosion resistance and excellent workability. Its workability property is a marked advantage as it allows the formation of complex designs using various metal forming techniques. Among all the available metal forming techniques casting is considered the simplest, mature and versatile way of forming aluminum into wide variety of products. Large numbers of a given casting can be produced quickly due to its mass production. For example; cast engine blocks and transmission cases are produced on large scale in the automotive industry. Furthermore aluminum or any other light weight metal can be preferably produced only as castings.The aluminum casting market is witnessing considerable growth due to the advancements in technological capabilities and high efficiency of aluminum cast products. Demand for aluminum casting is high from OEM as aluminum is preferred over iron and steel products in the transportation. High investments in R&D and technology upgrade techniques undertaken by major OEMs, auto manufacturers and related suppliers are key factors driving the demand for cast aluminum products. Stringent emissions regulations enacted by government are driving the demand for aluminum, as vehicle weight is a key to meet these regulations. However, factors such as requirement of high capital investments, significant plant construction or expansion and high cost of labor are hampering the market.

Request For Report Sample: https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=31241

Based on raw material, the market can be segmented into pure aluminum and alloy aluminum. An alloy offers different physical properties than the elements it is made up of. Aluminum in its pure form is not considered useful as it has low tensile strength. However, when mixed with other elements, the alloys of aluminum exhibit remarkable improvement in mechanical properties. Pure aluminum is employed in the electronic industry in the production of semi-conductor modules.

Considering the various processes used for casting aluminum products the aluminum casting market can be classified into die casting, permanent mold casting, sand casting and others including centrifugal castings and lost wax castings. In terms of application the market can be segmented into transportation, industrial, electrical & electronics, construction and others.

Increase in industrial automation in the aluminum die-casting industry has boosted productivity due to highly durable cast parts that require minimum machining and finishing. The die-castings segment has been expanding in transportation and industrial sectors. It is anticipated to increase significantly in in the near future as aluminum die casted products lower the overall weight of the vehicle thereby reducing fuel consumption and improving the performance of the vehicle. Aluminum die-casted power train and engine areas is the one important way in which OEM’s could achieve this. This is one of the major reasons for the predicted growth in transportation sector and die -castings as well Aluminum permanent mold casting is used more widely than sand casting as dispensable mold is employed in the latter. The word permanent does not mean that the molds last forever. In fact, the service life of the mold depends largely on the pouring temperature, the material of the mold and complexity of the component being cast. These factors are driving the usage of die casting for producing aluminum cast products.

In terms of geography, Asia-Pacific is anticipated to lead the global aluminum casting market. Rise in population in Asia-Pacific is anticipated to increase the demand for vehicles for transportation thereby boosting the demand for aluminum casted products. North America and Europe are anticipated to be the major regions of the aluminum casting market due to the advanced manufacturing capabilities. Latin America and Middle East & Africa is the emerging hubs of the aluminum casting market.

Request For Report Table of Content (TOC):https://www.transparencymarketresearch.com/sample/sample.php?flag=T&rep_id=31241

Key players operating in the aluminum casting market include Alcast Technologies, Alcoa, Aluminum Corporation of China Limited (Chalco), Gibbs Die Casting, Bodine Aluminum, Fairfield Aluminum Casting Company (FALCO) and China Hongqiao Group Limited.

About US

Transparency Market Research (TMR) is a next-generation provider of syndicated research, customized research, and consulting services. TMR’s global and regional market intelligence coverage includes industries such as pharmaceutical, chemicals and materials, technology and media, food and beverages, and consumer goods, among others. Each TMR research report provides clients with a 360-degree view of the market with statistical forecasts, competitive landscape, detailed segmentation, key trends, and strategic recommendations.

Contact US

State Tower,

90 State Street,

Suite 700,

Albany NY - 12207

United States

Tel: +1-518-618-1030

Website: https://www.transparencymarketresearch.com/

Email: sales@transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aluminum Casting Market Report Offers Intelligence and Forecast till 2017 - 2025 here

News-ID: 853056 • Views: …

More Releases from Transparency Market Research

Diabetes Supplements Market to Reach USD 13.4 Billion by 2031 as Preventive Nutr …

The Diabetes Supplements Market is witnessing steady expansion as rising diabetes prevalence and increasing emphasis on preventive healthcare drive demand for nutritional products that support blood sugar management and metabolic health. Valued at approximately US$ 8.4 billion in 2020, the market is projected to grow at a healthy pace and reach around US$ 13.4 billion by 2031

With diabetes emerging as one of the most pressing global health challenges, consumers are…

Drugs of Abuse Testing Market to Reach US$ 18.7 Billion by 2031, Growing at 13.5 …

The global drugs of abuse testing market was valued at US$ 5.9 Bn in 2022 and is projected to expand at a robust CAGR of 13.5% from 2023 to 2031, reaching US$ 18.7 Bn by the end of 2031. The market is witnessing strong momentum due to the rising incidence of drug abuse worldwide, increasing regulatory oversight, and the introduction of technologically advanced screening solutions.

Access key findings and insights from…

Power Lawn and Garden Equipment Market Size Forecast to USD 188.4 Billion by 203 …

Power Lawn and Garden Equipment Market Outlook 2036

The global power lawn and garden equipment market was valued at US$ 93.9 Billion in 2025 and is projected to reach US$ 188.4 Billion by 2036, expanding at a steady CAGR of 6.6% from 2026 to 2036. Market growth is driven by increasing residential landscaping activities, rising demand for battery-powered equipment, expanding commercial landscaping services, and growing consumer interest in outdoor aesthetics.

👉 Get…

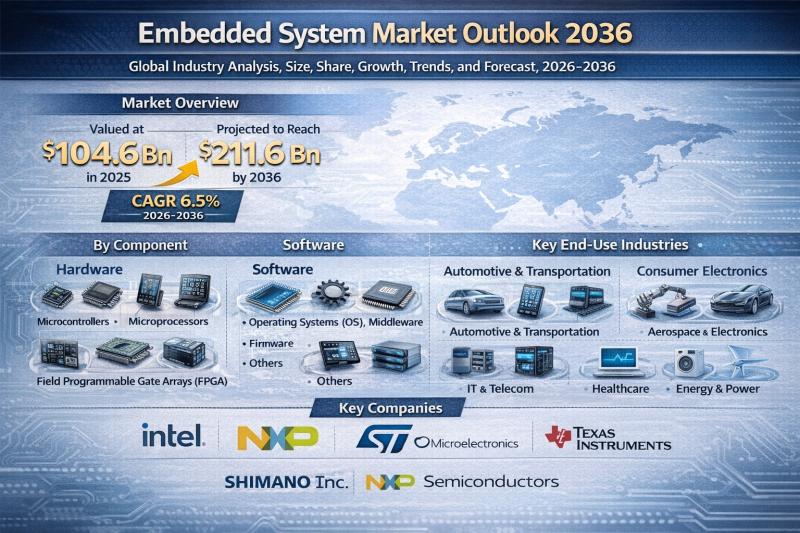

Global Embedded System Market to Reach USD 211.6 Bn by 2036, Expanding at 6.5% C …

The global embedded system market is poised for steady and sustained growth over the next decade, driven by rapid digital transformation across industries. Valued at US$ 104.6 Bn in 2025, the market is projected to reach US$ 211.6 Bn by 2036, expanding at a CAGR of 6.5% from 2026 to 2036. The increasing integration of embedded systems in automotive electronics, industrial automation, and IoT-enabled devices is positioning the industry as…

More Releases for Aluminum

New Aluminum Material-Aluminum Foam Application Summary

Aluminum Foam [https://www.beihaicomposite.com/aluminum-foam-tag/] Characteristics

Ultra-lightness

The density is 0.2~0.4g/cm3, which is about 1/10 of the density of aluminum, 1/20 of the density of titaNium, 1/30 of the density of steel, 1/30 of the density of steel, and 1/3 of the density of wood.

Sound Absorbability

Aluminum foam [https://www.beihaicomposite.com/about-us/] can be used to muffle and reduce noise by absorbing sound energy through the vibration of the pores' walls.

Heat resistance

It has high heat resistance; the general…

5083 medium-thick aluminum plate 5083 marine aluminum plate 5083 automotive alum …

5083 aluminum plate(https://www.mingtai-al.com/5083-Aluminum-Sheet.html) is a typical aluminum-magnesium alloy with light weight and high strength. With its excellent performance, it can be widely used in many industries such as automobile manufacturing, shipbuilding and rail transportation. With the vigorous development of lightweight, the demand for 5083 medium-thick aluminum plate in aluminum tank trucks and marine aluminum plates has increased.

5083 medium-thick aluminum plate-5083 marine aluminum plate-5083 automotive aluminum plate manufacturer introduction

In recent years,…

Yocon Aluminum Announces Availability of 3003 Aluminum Coil

Yocon Aluminum, a leading supplier of aluminum coil products in China, today announced the availability of 3003 aluminum coil. The company's new product is made from high-quality, mill-finished 3003 alloy and features excellent formability, weldability, and corrosion resistance. It is ideally suited for a wide range of applications in the transportation, construction, and industrial markets. With its outstanding properties, 3003 aluminum coil is quickly becoming a preferred choice for customers…

Yocon Aluminum china factory offers 3003 Aluminum Coil

Yocon Aluminum china factory is proud to offer 3003 aluminum coil. This high-quality product is perfect for a variety of applications, and we are confident that you will be satisfied with its performance. We are committed to providing our customers with the best products and services possible, and we look forward to helping you meet your needs. Contact us today to learn more about our 3003 aluminum coil!

In an effort…

Yocon Aluminum Supplies Aluminum Foil Coils for Major Appliances

Yocon Aluminum, a leading manufacturer and supplier of aluminum foil coils, has announced that they are now supplying major appliance manufacturers with their high-quality aluminum foil coils. With over forty years of experience in the industry, Yocon Aluminum is known for their dedication to quality and customer satisfaction. Their products are used in a variety of applications, including air conditioners, refrigerators, and freezers. When it comes to choosing a supplier…

Aluminum Frp Market Size, Status and Global Outlook 2021-Shandong Nanshan Alumin …

The MarketInsightsReports has published the obtainability of a new statistical data to its repository titled as, Aluminum Frp market. The comprehensive report provides useful insights into Market growth, revenue, and market trends, in order to enable readers to gauge market scope more proficiently. Furthermore, the report also sheds light on recent developments and platforms, in addition to distinctive tools, and methodologies that will help to propel the performance of industries.…