Press release

Fully automated hardness testing after heat treatment

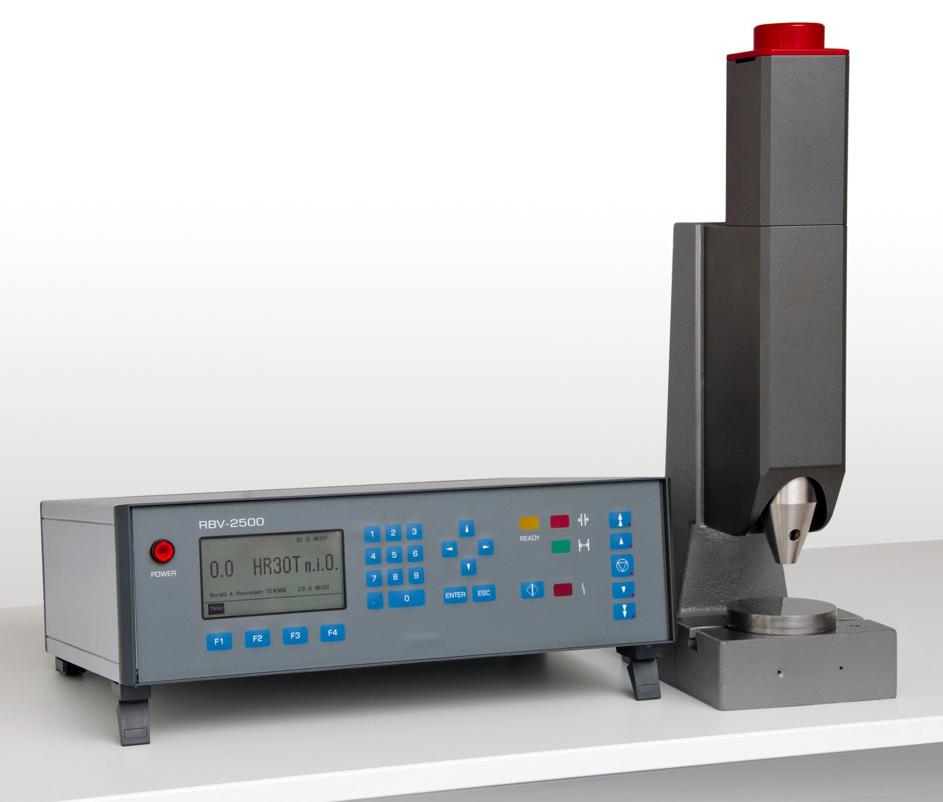

The latest hardness testing machines of BAQ GmbH are configured for the automated testing in production lines. Due to the high measuring speed, 100 % check-ups can be carried out while production. The standardized Rockwell or Super-Rockwell testing method is selected according to the measuring task. The test load range can be between 15 kg and 150 kg. For this reason it is not only possible to measure steel parts, but also to carry out the quality control of aluminium components directly after the heat treatment.Compared to the Brinell process, which is mostly used in testing aluminium, the Rockwell processes offer various advantages:

no optical evaluation, smaller test loads possible, speed, easy to automate.

Thanks to the new design, the compact testing modules can be integrated into existing production lines. They can be mounted almost in any order and measure, because of the new function, on inclined surfaces as well. The size of the parts that can be tested is not limited in contrast to hardness testing machines in the usual construction.

Each testing machine consists of the hardness testing module and a seperate control unit, which can be e.g. placed into a control box. In the manual mode the operation is carried out via the control unit. The automatic operation with a higher-level control unit uses input and output switches. The measuring result is evaluated according to the set limits and the switching outputs are set accordingly. The hardness value can be queried via USB or the RS232 interface.

BAQ GmbH is operating in the field of material testing since 1992. The product range covers stationary and portable hardness testers (Vickers, Rockwell, Brinell, Shore, impact hardness and ultrasonic contact impedance (UCI) method) as well as devices for testing layer thickness, abrasion resistance, scratching resistance and coating adhesion strength. These devices are used in all areas of material testing, e.g. inspection of incoming goods, production, research and development. More than 20 years of experience and continuous cooperation with the Fraunhofer Institute for Surface Engineering and Thin Films and others as well as in-house development and production in Germany guarantee good quality and optimal service. BAQ also offers optimized solutions for special requirements.

BAQ GmbH

Hermann-Schlichting-Str. 14

D-38110 Braunschweig

+49 5307 95102 -0

www.BAQ.de

info@baq.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Fully automated hardness testing after heat treatment here

News-ID: 803052 • Views: …

More Releases from BAQ GmbH

Hardness tester MIC 10 not longer available

Hardness tester MIC 10: The device's manufacturer GE Sensing & Inspection Technologies (Krautkramer) terminated the production at the end of October 2017.

For this reason, the wideley-used UCI hardness tester MIC 10 is not available anymore. After the device has not been developped for many years, the manufacturer has now drawn a line.

A modern alternative is offered by the company BAQ GmbH. With the alphaDUR mini, the alphaDUR II and the…

More Releases for Rockwell

Overload Relays Market May See a Big Move | Rockwell Automation, Delixi Group, S …

Advance Market Analytics published a new research publication on "Global Overload Relays Market Insights, to 2030" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study, you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market-associated stakeholders. The growth of the Overload Relays market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive PDF Sample Copy of…

Timing Relay Market offers huge growth opportunities for the future ; Schneider …

This study provides insights about the Timing Relay Market in regards to its uses and benefits. We at Crystal Market Research (CMR) provide updated information that is beneficial in decision making regarding business investments.

Eminent Players:

The leading players in the timing relay market are Schneider Electric, Rockwell Automation, Siemens, Rockwell Automation, Eaton Corporation and ABB Group. Expansions and Investments was the most widely implemented strategy by major players in the market…

Timing Relay Market Growth and Business Demand for Manufacturers: Schneider Elec …

Competitive Insights:

The leading players in the timing relay market are Schneider Electric, Rockwell Automation, Siemens, Rockwell Automation, Eaton Corporation and ABB Group. Expansions and Investments was the most widely implemented strategy by major players in the market from 2014 to 2017. It was trailed by new product developments, mergers & acquisitions and contracts & agreements.

For more information, click on the below link @ https://www.crystalmarketresearch.com/report/timing-relay-market .

The Timing Relay Market is segmented…

Tubing Packers Market Size 2017 Rockwell Automation

A market study based on the " Tubing Packers Market " across the globe, recently added to the repository of Market Research, is titled ‘Global Tubing Packers Market 2017’. The research report analyses the historical as well as present performance of the worldwide Tubing Packers industry, and makes predictions on the future status of Tubing Packers market on the basis of this analysis.

Get Free Sample Copy of Report Here :…

Global Rockwell Hardness Testers Market 2017

The report entitled Global Rockwell Hardness Testers Market 2017 presents key insights into the global Rockwell Hardness Testers market along with the latest up-to-date industry details and forthcoming Rockwell Hardness Testers industry trends, which will assist the readers to focus on product specification and end users driving the overall market revenue and profitability.

Report Keynotes:

The main motive of the report on "Global Rockwell Hardness Testers Market 2017" is to study comprehensive…

Rockwell Trading Moves Headquarters to Austin

Rockwell Trading Inc. (rockwelltrading.com), a leading provider of small-investor education and training, today announced it moved its headquarters to Austin, Texas. The move was precipitated by company's realization that Austin is a hub for day trading activity.

"We originally selected Austin when we decided to expand our operations because of the large number of tech-savvy small investors,” said Markus Heitkoetter, Rockwell Trading CEO. After careful evaluation, we realized moving the headquarters…