Press release

Intertronics advance superior adhesive performance through plasma surface treatment

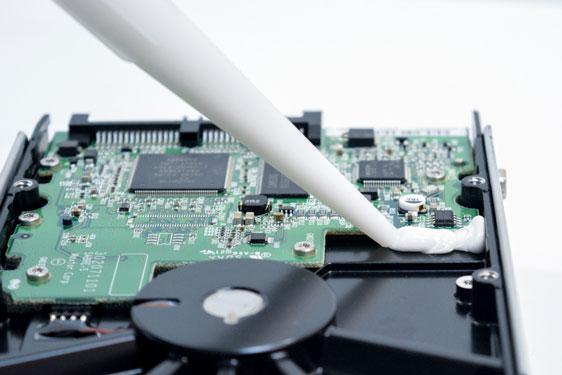

Recent work by engineers at Intertronics’ partners Relyon Plasma has demonstrated the substantial increases in bond strength achievable with the use of plasma surface treatment, which can improve adhesion on many substrates, including those which are seen as difficult to bond. Plasma surface treatment can enable otherwise impractical bonds and improve assembly performance, while saving time and money in the concept-to-market cycle.Two big areas of interest are structural plastics and the inter-mixing of plastic/composite/metal components in high performance applications.

Plastics are usually characterised by inert surfaces with surface energies between 20 and 40 mN/m. In order to wet a surface, however, the surface energy of the polymer must exceed the one of the paint, ink or the adhesive. This condition can be achieved through a plasma treatment or “activation” of the surface, raising the surface energy and improving the wettability of the adhesive.

More important than the improved wetting are the chemical groups which are newly incorporated into the surface. This so-called surface functionalisation creates additional chemical “bonding anchors” or “bonding sites” for the adhesive.

The relative bond improvement is illustrated for various plastics and adhesives based on the increase of shear force until bond failure. Depending on the substrate and adhesive, it is possible to achieve shear strengths of up to 50 MPa through an optimized treatment with the Plasmabrush PB3 Plasma Surface Treatment System from Relyon Plasma.

Increase of the shear strength after a short plasma treatment with dry compressed air at atmospheric pressure is demonstrated for various technical thermoplastic materials: PBT (polybutylene terephthalate), PE (polyethylene, HDPE) and PA6 (polyamide), and comparable effects are found on polypropylene (PP) and LCP polyester (LCP).

Adhesive bonding of plastics to metals is an application which is growing. A typical example is the bonding of composite materials (carbon fibre, CFRP) and aluminium (Al) materials in the automotive sector. Various adhesives can meet the structural requirements of the bond. However, a polymer matrix of carbon fibre reinforced materials can have poor adhesion characteristics. In this case, an atmospheric plasma treatment can be simply integrated into the bonding process.

When atmospheric pressure plasma processes are used with air, then mainly oxygen and hydroxyl groups are deposited on the plastic surface. These groups can form covalent bonds with the adhesive, helping to improve adhesive strength. The oxygen percentage close to the surface can increase by a factor of three (x3), achieving shear strengths above 20 MPa. In case of a composite based on a PA6 matrix, this can quadruple the strength. This improved shear strength can still be demonstrated even after several weeks.

If instead of compressed air, other process gases are used such as nitrogen or forming gas (N2/H2), it is possible to generate other specific groups on the surface, with appropriate results in adhesion and ultimate bond strength.

Intertronics are happy to run tests with engineers on their own parts at the Technology Centre near Oxford.

For further information please see www.intertronics.co.uk/plasma or visit the Intertronics blog at intertronics.co.uk/blog.

Intertronics supplies adhesives, coatings, sealants and equipment to customers with high technology, high performance assembly applications. Their customers are manufacturers in industries such as electronics, medical devices, plastics, optical, automotive, energy, defence and aerospace.

Intertronics specialise in adhesives and adhesive systems, namely bonding, coating, sealing, encapsulating, potting, masking and gasketing products, together with the most appropriate equipment and accessories for surface preparation, mixing, application, dispensing, and curing them. The provision of insightful technical and applications guidance is a cornerstone of their business. Intertronics can help you find the optimal materials and processes for the manufacture, assembly or repair of your products, safeguarding and enhancing performance and integrity and, in turn, your profitability and reputation.

Ever since being established in1979, when their main market was the printed circuit board assembly industry, Intertronics has enjoyed a reputation for customer focus, excellent service and post-sales support. They now supply over 3,000 regular customers, including multinational manufacturers, production facilities, specialist design and development businesses, universities, training organisations and government establishments.

The Intertronics Technology Centre, located in Oxfordshire with excellent road and rail links, is custom-designed for hands-on demonstrations and trials, hosted by their product specialists.

Intertronics

Unit 17, Station Field Industrial Estate

Banbury Road

Kidlington

Oxfordshire

OX5 1JD

Tel: 01865 842842

email: info@intertronics.co.uk

www.intertronics.co.uk

Press contact: Peter Swanson

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Intertronics advance superior adhesive performance through plasma surface treatment here

News-ID: 780178 • Views: …

More Releases from Intertronics

Tidy workplace and precise dispensing results from preeflow® eco-PEN450 for Fra …

Franklin Electric, a leading international manufacturer of water and fuel pumps, faced a difficult challenge when tasked with optimising dispensing processes at their Czech production site.

The objective was to reduce the waste of UV curing material during the application process. Dispensing equipment previously used by Franklin Electric had been very inaccurate, creating unnecessary waste, high material costs and additional cleaning efforts.

After completing preliminary tests, the team at Franklin Electric were…

WACKER ELASTOSIL® N9111 tin free silicone from Intertronics avoids conflicting …

WACKER ELASTOSIL® N9111 from Intertronics is a tin-free single part RTV silicone adhesive sealant, with a neutral cure chemistry, producing a non-corrosive seal that does not inhibit other materials such as platinum cure silicones. This, along with its UL94 V-0 rating, makes it a strong candidate for electronics manufacturing, especially for gap filling, component ruggedisation, and form-in-place gasketing. It is stocked in depth at Intertronics for next-day delivery.

Elastosil N9111 is…

preeflow precision dispensing system from Intertronics improves quality and redu …

The automobile manufacturing industry places high demands on suppliers with regard to process reliability, quality and efficiency. To meet these challenges, a preeflow customer had to optimise his application of a two-part sealant to make a form-in-place (FIP) gasket. In his previous process, the dispensed sealant bead exceeded the tolerance limits at the point where the gasket loop completed and the sealant overlapped itself. In addition, a key process variable…

New guidance from Intertronics – How to specify a dispensing robot to increase …

Automated application of adhesives, potting compounds or encapsulants, sealants, FIP gaskets, temporary masking, lubricants, or other liquids, fluids or pastes provides productivity benefits over manual application, including consistency, speed and accuracy. As selection of a dispensing robot is sometimes a daunting task, Intertronics, a specialist adhesives and dispensing company, has compiled a short piece of guidance on how to specify a dispensing robot. The full guidance can be found on…

More Releases for Plasma

Blood Plasma Freezers Market Safeguarding Plasma Derivatives: Blood Plasma Freez …

Global Blood Plasma Freezers Market Worth $772.0 Mn by 2031 - Exclusive Report by InsightAce Analytic Pvt. Ltd.

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global Blood Plasma Freezers Market- (By Type (Manual Defrost, Automatic Defrost), By Application (Hospital, Laboratory), By Region, Trends, Industry Competition Analysis, Revenue and Forecast To 2031."

According to the latest research by InsightAce Analytic, the Global Blood Plasma Freezers Market…

Contract Plasma Coating Service Market Analysis, Size, Share, Trends, Growth And …

The Global Contract Plasma Coating Service Market report is added by WMR to its database to offer a complete assessment of the factors influencing an overall market growth trend. The research covers significant data and proves to be a handy resource document for industry experts. The research is a perfect balance bridging both qualitative and quantitative information of this market. Quantitative statistics with qualitative reasoning related to market size, share,…

Cold Plasma Market Analysis By Top Keyplayers - Plasma Air, Atmospheric plasma t …

The "Cold Plasma Market" is expected to reach USD xx.x billion by 2031, indicating a compound annual growth rate (CAGR) of xx.x percent from 2024 to 2031. The market was valued at USD xx.x billion In 2023.

Growing Demand and Growth Potential in the Global Cold Plasma Market, 2024-2031

Verified Market Research's most recent report, "Cold Plasma Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," provides an in-depth examination…

Contract Plasma Coating Service Market Revenue Sizing Outlook Appears Bright| He …

The Latest research study released by HTF MI "Global Contract Plasma Coating Service Market with 120+ pages of analysis on business Strategy taken up by key and emerging industry players and delivers know-how of the current market development, landscape, technologies, drivers, opportunities, market viewpoint, and status. Understanding the segments helps in identifying the importance of different factors that aid market growth. Some of the Major Companies covered in this Research…

Contract Plasma Coating Service Market Players Leveraging on Growth Opportunitie …

The Most recent study offered by "Stratagem Market Insights" focuses on Contract Plasma Coating Service Market size, share, growth rate, and market trends, as well as the parameters and factors influencing it in both the long term and short term. The report investigates the market trends in order to assess its current and future potential. Our Market analysis also provides market participants and new entrants with a comprehensive view of…

Cold Plasma Market Size, Share - Global Industry Forecast 2032 | Relyon Plasma G …

The market research report offers an in-depth analysis of the Cold Plasma market, helping players to prepare for the increasing hurdles ahead and ensure continued business expansion. With impeccable analysis, exhaustive research, and accurate forecasting, we provide a clear and authoritative study of the global Cold Plasma market, backed by data and figures that have undergone a rigorous verification process. This research is an exhaustive, comprehensive and carefully curated source…