Press release

Flexible couplings to connect shafts backlash-free

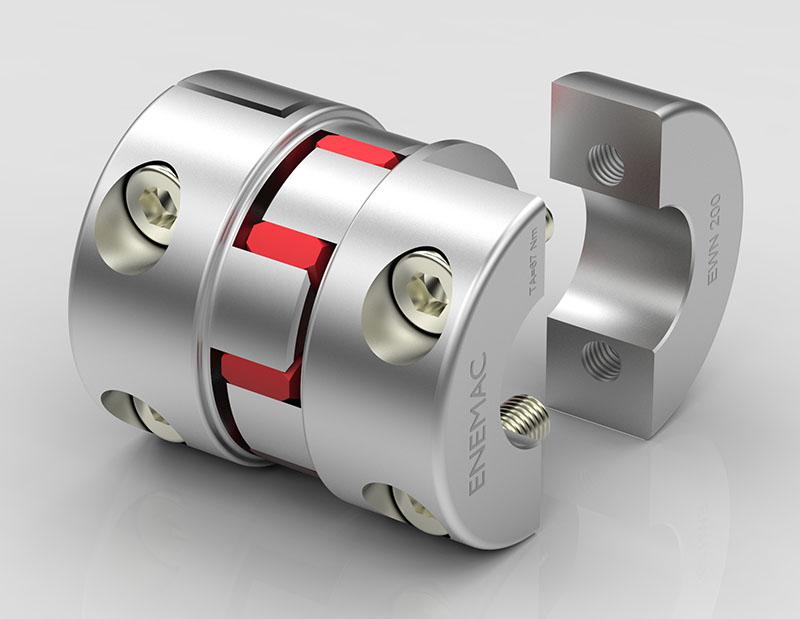

A new product line has been added to ENEMAC's portfolio, the jaw coupling EWNIn generell technically mature, pluggable elastomer- or claw couplings are mainly used in demanding drives of general mechanical engineering, where zero backlash and easy handling are required.

The new series EWN, with its two half-shell hubs, precisely combines these two properties and, furthermore acts electrically insulating by means of the involute-shaped elastomeric insert. This elastomer spider connects the two hubs with low prestressing and absorbs the vibrations occurring in the drive train.

Type EWN is very suitable for hard-to-reach shafts. A secure and force-fitting shaft connection is always guaranteed.

The compact series is available in 13 sizes and is designed for torques up to 2000 Nm at up to

393 K. Shafts between 8 and 100 mm can be absorbed.

Founded in 1981 in Kleinwallstadt am Main, the ENEMAC GmbH (Society for Energy and Mechanical Engineering) looks back on more than 30-year history. Steady progress and recent developments have extended and modified the product range of ENEMAC over the decades.

In the early years focusing on the topic of machine safety for feed drives. With the safety clutch type ECT-R ENEMAC entered the market in the machine tool industry. Further series followed to service the needs of this market segment.

During the 1990s, the focus shifted towards food and packaging industry. ENEMAC specialized on rust-free safety couplings made of stainless steel to accomodate the high hygiene and production requirements in this area. In parallel, lower cost versions of safety couplings, the so-called overload clutches have been developed. To complete the product range shaft couplings in different variants and versions have been integrated into the offer.

In recent years, the company ventured a step above the usual "clutch plate" addition in the direction of clamping technology. Mechanical clamping screws and clamping nuts and and hydromechanical spring clamping cylinders provide an alternative to simple workholding equipment such as clamps or clamping claws as well as to semi or fully automatic clamping devices.

ENEMAC clamping technology is very versatile. Whether for tool or workpiece clamping, in materials handling, bending and welding engineering - either as original equipment or aftermarket item.

What value this new product line in the company's development will take, the future will tell. The company will face the new challenges of the market and be constantly striving to meet customer needs individually and in highest quality.

Enemac GmbH

Daimler Ring 42

63839 Kleinwallstadt

GERMANY

Phone: 0049/6022/7107-0

Fax: 0049/6022/22237

www.enemac.org

info@enemac.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Flexible couplings to connect shafts backlash-free here

News-ID: 772030 • Views: …

More Releases from Enemac GmbH

New stainless half-shell metal bellows coupling EWR

The EWR half-shell version made of stainless steel is new in the range of couplings specialist Enemac from Kleinwallstadt. The use of A4 or A2 stainless steels makes it suitable for use in demanding environments and in sterile or even acidic applications, as well as in the food and medical sectors.

It is particularly suitable for use in systems that are difficult to access, where space is very limited and the…

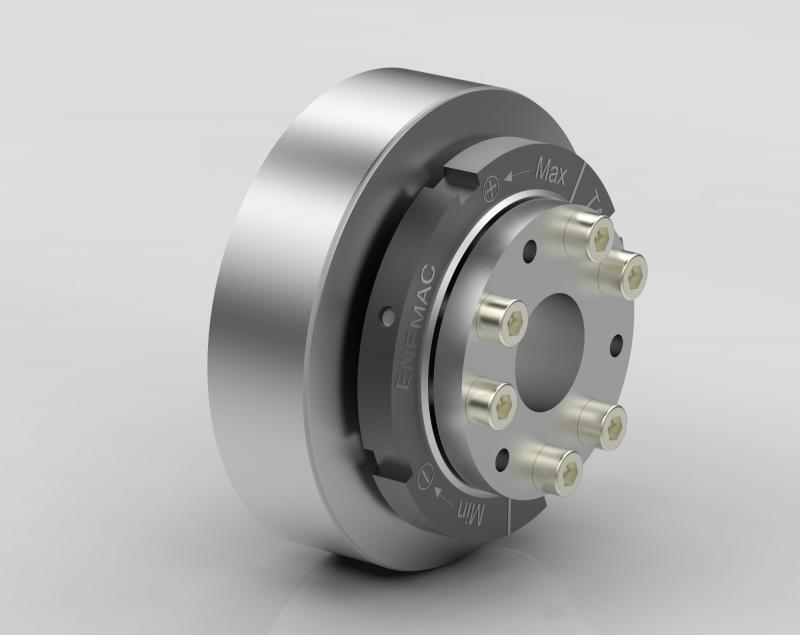

Torque limiter type ECA for belt drives

Applications of torque limiters can be found in all sectors of technique, in each and every machine or facility where torques have to be limited to protect machines or products from overload.

The torque limiter type ECA, which is especially engineered for belt drives prevents such overload damages or at least reduces them to a minimum.

Particular worth was put on compulsion-cutting and fast switching function. Simple, light elements avoid adverse…

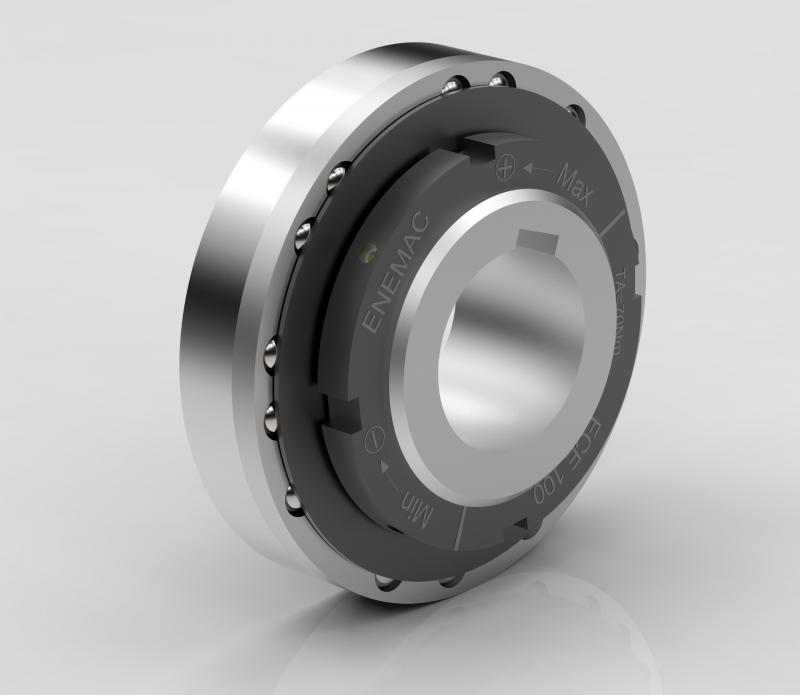

Torque Limiter ECE in a very flat design. Robust and perfected safety without c …

Mechanical Torque Limiters are used in all kinds of technical application areas. Their job is the protection of products and expensive devices.

Torque Limiters react very sensitive to the smallest increase of torque and disconnect the drive from the following masses in a split second. That's why they are also called "Safety Couplings". The disconnection is forced, that means it has no effect on the function in case of an electrical…

New stainless half-shell metal bellows coupling EWR

The EWR half-shell version made of stainless steel is new in the range of couplings specialist Enemac from Kleinwallstadt. The use of A4 or A2 stainless steels makes it suitable for use in demanding environments and in sterile or even acidic applications, as well as in the food and medical sectors.

It is particularly suitable for use in systems that are difficult to access, where space is very limited and the…

More Releases for EWN

Slack Wax Market: Investment Opportunities and Profitability Analysis for Foreca …

Slack Wax Market Snapshot: Insight into Market Trends and Movements

Slack wax is a byproduct of the oil refining process, primarily used for producing candles, lubricants, and cosmetics. The Slack Wax market is experiencing notable growth due to increased demand in various industries, particularly in candle manufacturing and personal care products. Rising consumer awareness regarding sustainable and eco-friendly products is driving the use of slack wax, as it serves as a…

Foundry Coke Market Forecast: Revenue Trends and Growth Projections for period f …

Market Overview and Report Coverage

Foundry coke is a high-carbon product derived from the carbonization of coal, specifically designed for use in foundries as a crucial fuel and reducing agent in steel and iron production. Its properties include low ash content, high strength, and excellent thermal stability, making it ideal for metallurgical processes.

The current outlook for the foundry coke market is optimistic, driven by the growing demand for steel and iron…

Wearable Medical Robot Market Size 2024 to 2031.

Market Overview and Report Coverage

A Wearable Medical Robot is a device that is worn on the body and is designed to assist individuals with medical needs such as mobility, rehabilitation, or monitoring of health metrics. These robots can be used in various healthcare settings including hospitals, rehabilitation centers, and even in the home.

The future outlook for the Wearable Medical Robot Market is promising, with a projected growth rate…

Elesa ELECOLOR® machine tool components

The Elesa ELECOLOR® program offers corporate compatibility for machine tools and other OEM machinery. For example - Top Automazioni, a mechanical company based in Poggio Torriana (Rimini – Italy), is today the most innovative company in Italy in the production of bar feeders. To assist them in maintaining this leadership Top Automazioni have chosen a selection of Elesa standard components with yellow inserts to represent its corporate colour, as well…