Press release

New Flowable Fill for backfilling geothermal collectors

A modified cementitious and water absorbent Flowable Fill for constructing earth-touching and thermo- activatable building elements for geothermal storage & transfer purposes in ground source heat pump systems to establish centralised or decentralised underground mid- or long-term (seasonal) thermal storage units, and develop more efficient geothermal ground spaces right beneath or nearby-located to residential, industrial or commercial houses or buildings, –strong enough to be build over, environmentally friendly, maintenance-free, storage efficient and cost effective, long lasting, and corrosion resistant. And heat storage is the future key-technology for every modern energy-efficient district or unitary Green Building Design utilised preferred by alternative or renewable energy sources.Background (state-of-the-art):

Buildings of tomorrow require a combination of minimised onsite energy generation incorporating maximised renewable thermal energy sources, ultra-efficient building and insulation materials and equipment; waste heat recovery, and short-, mid-, and long-term thermal storage.

Ultra-efficient building and super-insulation materials are necessary to reduce the general thermal energy demand and to make smaller thermal storage capacities possible. Narrow city right-of-ways and private land space is limited and growing expensive, so decentralised underground heat storage options are generally advised, which uses no open land or interior room space, and can be build over, and make the distance of transportation as short as possible. Those underground storage systems require less insulation, because they are covered by the particular building and embedded in the ground heat.

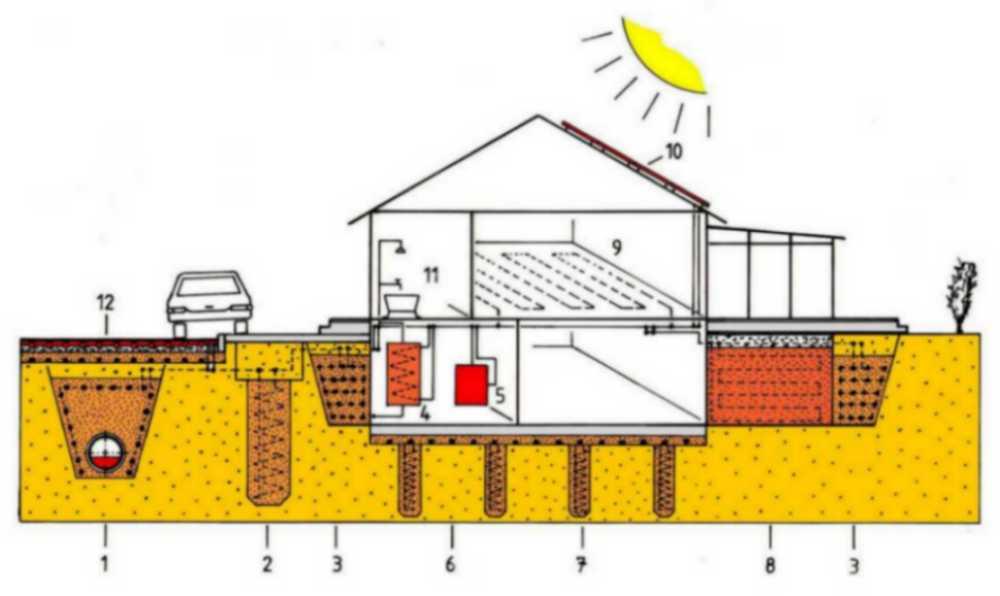

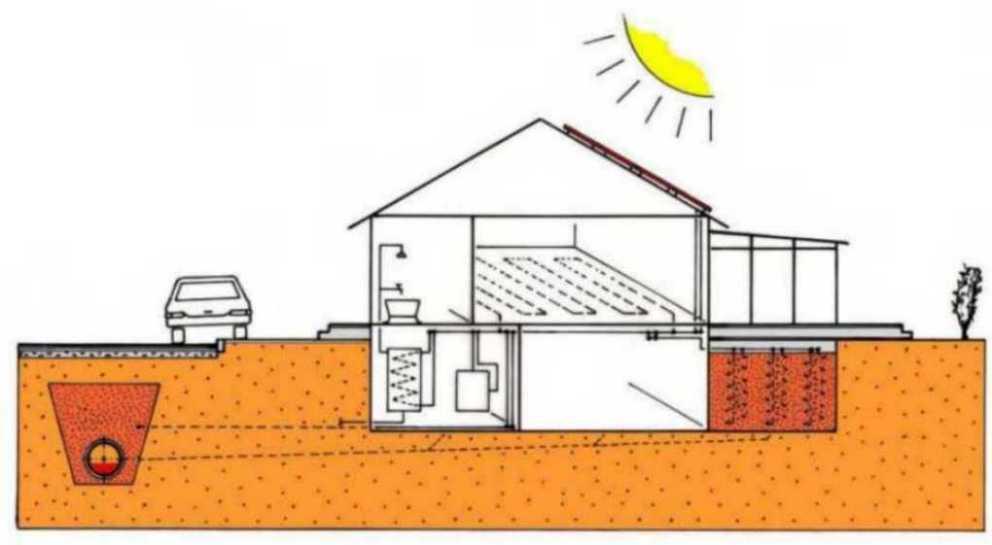

Solar energy is one of those most potential renewable energy sources, which can be used directly for heating & cooling purposes, but also indirectly by using the shallow underground as a geothermal reservoir. Today, solar-thermal collectors (see in the graphic 10) are working quite well, but in order to make them more efficient, it is advised to run them with a short-term indoor storage tank (4) in combination with a big enough outside underground mid-term storage unit (8), and long-term (seasonal) geothermal storage & transfer systems (1-3;6-7;12) to maintain a sustainable and steady thermal energy supply all year round, that means also during nights and periods of cloudy, sunless days, and in the wintertime (seasonal use).

So beside the solar energy the shallow ground heat is a high potential but low temperature renewable heat source with relatively low extraction values, into which other environmental heat sources, like the waste heat from untreated wastewater collection systems (1), low temperature heating & cooling systems like floor/wall/ceiling heating & cooling systems (9), and air-conditioning, and the heat from biomass boilers or micro-cogeneration and heat pumps (5) also can be buffered. A heat pump is necessary to raise the relatively low geothermal heat temperature to a comfortable heating & cooling temperature level.

And to charge and extract the heat or cold to/from the shallow underground commonly horizontal or vertical heat pipe exchanger are used, like horizontal-loop exchanger, trench collectors, and horizontal or vertical spiral collectors, also called “Slinky” collectors, installed not deeper than approx. 20 feet (6 m) into the ground.

These devices are conventionally embedded into granular fill resp. in a sand layer, or fine excavation material from the same site. Compacting by vibration is not advised in this case because the collector pipes might be get damaged. So mostly backfill compacting by water and careful tamping by hand is used with more or less success regarding later surface settlements after the water seeps away and the backfill dries up and keep holes left. However, very important in this concern is, that maximum heat charging & extraction values can only be reached during later operation, if the backfill is always in firm connection to the collector pipes and as much as possible enriched with water. Because as is well known, that water saturated sand has a 4-part higher specific heat extraction output than dry, non-cohesive soil.

Only from a few projects we know that also or Flowable Fill was used yet, especially for to embed horizontal collector pipes into foundation sub-bases, or for to backfill low-strength energy piles. But in all cases the ground under closed building infrastructures, including the backfill, is mostly more or less dry depending on the groundwater level, and therefore less well-conditioned for heat charge and extraction.

Flowable Fill is a relatively new self-compacting, self-leveling, low strength concrete material, also called “Controlled Low Strength Material (CLSM)”, with an adjustable flowable consistency, used as an economical fill or backfill material as an alternative to compacted granular fill. While it costs more than a dry granular material, it does not need to be placed in lifts, spread, and compacted after each lift. It not require vibration or tamping, and has minimal subsidence. It is used as backfill for sewer and utility trenches, conduit encasement, pile excavation, and as a structural fill for foundation sub-bases, sub footing, floor slab base, and conduit bedding. More information is provided by NRMCA on their website http://www.nrmca.org/aboutconcrete/cips/17p.pdf.

New Thermo-Backfill-Material:

Based on the above described state-of-the-art and resulting market demand Orange Depot System has developed the idea of a new building material, which is a modified kind of Flowable Fill or CLSM, and has the innovative additional property of a very special porous and high-capillary structure for maximised water absorption and according heat storage capacity. It has the ability to get saturated with water up to over 45 % of its body volume so far depending on the recipe of the mixture and the individual requested compression strength of the finally hardened material. And it keep the water in its material structure to a great extent by capillary effect. If this material is used for forming heat storage or heat transfer elements in the ground during the time and operation the material will sweat out successively small portions of water on its outer surface. This water slowly will penetrate into the touching natural ground and will enrich more and more the surrounding soil with moisture, and develop a bigger and bigger ground space for potential heat storage. The lost water in the element by the time can be artificially refilled from the nearby residential rainwater system using a plastic duct system. To saturate a larger area a perforated duct system can be laid, like it is known from sub-irrigation system used in the landscape gardening.

And this new material can be build over after hardening without the need to build heavy-duty and expensive water basin, tank or reservoir constructions. It consists of conventional building components as like cement, lime, sand, soil, additives, and a special capillary agent, so it can be simply and conventionally manufactured, shipped, processed, and installed by low cost. This material saturated with water is not only able to store heat up to the boiling point but also cold temperatures around the freezing point, because it is frost resistant under certain conditions.

For charging and extracting the heat into and out of the material a plastic (PEX) pipe collector system can be easily embedded during the material is processed. The water saturated material encases the collector pipes absolutely form-locking without any voids, cavities, or air-bubbles left.

So this new material has beyond the favourable conventional material properties the additional advantage (added value!) of an extra-special heat storage & transfer ability.

Further advantages of this material are explained in the following recommended application options:

1 Thermo-activated Sewer Lines

Complete Sewer lines including the surrounding ground space can be used as a huge thermal storage system or net, if the trench is equipped with an appropriate collector pipe system before it is back filled by the new Thermo-Backfill-Material and saturated with water. In addition, newly laid sewer pipes can be produced with an spiral collector integrated in its pipe wall ex woks. Those sewer pipes are called “Multi-Purpose Sewer Pipe”, and more information about this new product is provide by the contact address below. The overbuild road covers and insulates this system in a perfect way. And the local resident e.g. can connect his passive solar house on a very short distance. From the economic point of view its rather advisable to install this system during sewer lines are newly laid, or replaced, or roads structurally are reconstructed.

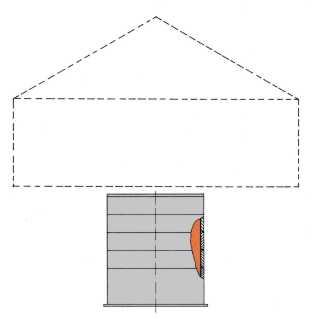

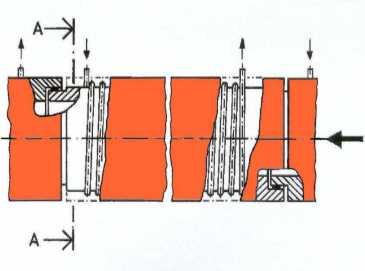

2 Vertical Spiral Collectors

Geothermal spiral collectors are primarily used in North America. In Germany they become more and more accepted. They have a high potential specific heat extraction, and their performance can be significantly increased if they are back filled by the Thermo-Backfill-Material and run with saturated water. The final construction is basically the same as a thermal activated concrete element embedded in the ground, which has solidly integrated a spiral collector system. Depending on the dimension and shape and number of those elements, they can be used as an appropriate big single thermal storage unit, or as a heat transfer pile, also called “Energy Pile”. If many of those energy piles are arranged like a field, they are very suitable for geothermal heat pump and storage systems with heating and cooling loads, and are predestined for to develop larger ground spaces up to a depth of approx. 20 feet (6 m). And in the case Thermo-Backfill-Material is used those piles have the additionally ability to moisture the surrounding soil for maximising heat charge and extraction. And those piles can be used as low-strength foundation piles too, but regarding corrosion aspects no reinforcement steel in the concrete is advised in this case.

3 Trench Collector around the house

After a house or building is erected in a construction pit, an trench around the house kept open. This ring-like trench can be equipped with an appropriate collector pipe system like described in 1 and back filled with the Thermo-Backfill-Material. By this way a huge additional storage system can be developed right beside each individual house or building.

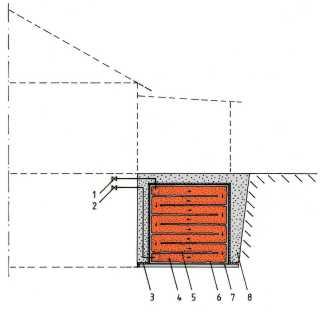

6 Thermo-activated Foundation Slabs

This geothermal use by thermal activated foundation slabs is well known, and the performance can be significantly increased, if the collector system is laid right on the natural ground of the construction pit and be embedded into the subbase made by the Thermo-Backfill-Material. Upon the subbase a perforated plastic duct system is laid in loops. Now the duct system is covered by a geo-membrane and an appropriate insulation layer before the structural foundation plate is finally concreted on.

7 Energy Piles

The before mentioned thermo-activated foundation slabs can perfectly combined with energy piles as described in 2 to develop a deeper ground space for long-term (seasonal) geothermal storage right under each house or building, with an optimised performance if the new Thermo-Backfill-Material saturated with water is used.

8 Mid-term Thermal Storage Block

Preferably right beside houses or buildings under garages, car ports, or patios or winter gardens appropriate big rectangular shaped mid-term storage blocks can be advantageously be placed, because they can be covered by the particular superstructure and by this way be insulated from above . Those blocks are operated in a temperature range between freezing and boiling point, an can be made of different building and storage materials or mediums. Basically a water saturated Thermo-Backfill-Material with integrated collector pipes of any configuration can be used too, if an indirect thermal charging system is wanted. But another, innovative heat storage conception by a new construction method using prefabricated concrete parts can be used, which can make able also a direct charging system by water circulation as an option. More information about this new conception have the contact address below.

12 Thermo-activated traffic areas

A further huge potential heat source can be developed by thermal activating the surface of roads, private and public places, and airport runways. Those surfaces can be used as a solar-thermal absorber by integrating heat exchanger piping into e.g. the asphalt pavement. The absorbed heat can be charged very simply into the ground right under those closed surfaces or into nearby located centralised district storage systems or decentralised residential underground buffer stores as described above. To store the heat right under those traffic areas in the ground it is advised to use geothermal storage and transfer systems preferably by the support of geothermal-activated units or elements with integrated heat collectors, as described above, using the particular right designed shape and volume and collector device configuration. Such a system can cool down all kind of pavement during summer and temper it during winter to keep them ice- and snow-free. No question – a huge future perspective.

Further options for construction, design, and operation are unlimited.

Realisation & Use:

The basic idea is patented in Germany and patent-pending in the USA.

The technology is in the prototype phase and needs finally specified regarding the different recipes and tailored product designs depending on local demands. Orange Depot System want to do this and the following marketing and sale by co-operation with appropriate local partners, e.g. cement & ready-mix concrete companies. If this is interesting for you, please contact the address below.

TEC MANAGEMENT is an engineering and consulting firm in the field of environmental friendly technologies with focus on underground infrastructures, and beside others specialised on alternative energy storage & supply.

Orange Depot System is the label, under which particular systems, products, and techniques are promoted.

TEC MANAGEMENT

Dipl.-Ing. Michael Henze

Mainring 10

D-63500 Seligenstadt

Germany

Phone: +49 (0)6182 / 897967

Fax: +49 (0)6182 / 897968

EMail: info@orangedepotsystem.com

Website : www.orangedepotsystem.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release New Flowable Fill for backfilling geothermal collectors here

News-ID: 72960 • Views: …

More Releases from TEC MANAGEMENT

Pit Heat Store with a Thermal Stratification Direct Water Charging System put up …

Pervious concrete filled with water used for constructing centralised or decentralised underground thermal storage units right beneath or nearby residential, industrial or commercial buildings, –strong enough to be build over, environmentally friendly, maintenance-free, storage efficient and cost effective, long lasting, and corrosion resistant- preferably erected with concrete masonry units. -The future key-technology for modern district or unitary renewable and low energy heating & cooling.

Background:

Buildings of tomorrow require a combination…

NEW BUILDING MATERIAL – for Green Building Solutions

A water absorbent kind of mineral-fixed building material for decentralised underground installation of long-term thermal storage units right beneath or nearby-located to residential or commercial houses or buildings, –strong enough to be build over, environmentally friendly, maintenance-free, storage efficient and cost effective, long lasting, and corrosion resistant. The future key-technology for modern district and unitary low energy heating & cooling systems utilised preferred by green energy sources .

Background:

Buildings of tomorrow…

Heat & Cold Storage beneath Residential and Commercial Buildings

Heat storage is an essential part of a very broad range of renewable energy systems: from solar collectors to biomass boilers, from micro-cogeneration to heat pumps. And Heat storage is an enabling technology: without it, renewable heating and cooling would not be possible. It is the road map to higher solar fraction up to 100 %.

The new Idea:

A Heat & Cold storage construction system made of water absorbent mortar …

Multipurpose Sewer Pipe with a "Slinky" Heat Pipe Exchanger

A new sewer pipe construction with an outside attached and into the pipe wall embedded spiral heat pipe exchanger for additional utilization of the surrounding ground heat and its storage capabilities and the wastewater heat as alternative heat sources for geothermal heat pump systems.

Background:

"Slinky" is the term commonly used rather than the imposing scientific name - curtate cycloid.

When used with geothermal heat pump systems, the Slinky application is…

More Releases for Material

Firestop Material Market

LOS ANGELES, United States: The global Firestop Material market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global Firestop Material market. For instance, the market dynamics section digs deep into the drivers, restraints, trends, and…

New Material Direction for Electric Toothbrushes - Si-TPV Soft Over Molded Mater …

When it comes to factors such as consumer experience or ergonomics, Si-TPV Soft Over Molded Material has had a huge impact on the improvement of various products such as electric toothbrushes, etc. Si-TPV is a Silicone Combine TPU developed and produced by SILIKE, a Thermoplastic Elastomer Manufacturer (Thermoplastic Elastomer Suppliers). Si-TPV material adopts Innovative Soft Slip Technology and Sustainable Overmolding Techniques, which can be used to make Stain Resistance Soft…

A new light on a misjudged material - Plastic waste: material for art

Used plastic bottles are not waste, but a valuable resource. They can be reprocessed in a variety of ways and transformed into new products or fresh energy. And into art. This is exactly what Ve-ronika Richterová does. The Czech artist creates fascinating sculp-tures made out of old PET bottles.

Plastic has inspired artists from the very beginning. The reason: plas-tic meets almost all technical and aesthetic requirements. It is a uni-versal…

Global Thermal Transfer Material Market, Global Thermal Transfer Material Indust …

Thermal conductivity refers as an important characteristic for several manufacturing operations. Thermal transfer properties of a variety of materials are effective in certain applications owing to natural molecular structure that allows for direct heat-transfer. Thermal transfer materials are extensively used to manufacture the heat conductive adhesive tapes, printable products and polymer sheets. These polymer sheets are utilized for barcodes, labeling, and QR code labels for retailing, logistics, and consumer goods.…

The Future of Smart Material Market Runs Through the Material Industry

Smart Materials Market is expected to garner $72.63 billion by 2022, registering a CAGR of 14.9% during the forecast period 2016-2022. Smart materials are adaptive or intelligent materials which pose intrinsic and extrinsic capabilities. These can be altered by external stimuli, such as moisture, temperature, electromagnetic field, and pressure to obtain the desired functional effects. In addition, these materials are dynamic in nature and respond to their immediate interaction environments…

Global Regenerative Artificial Skin Sales Market Research Report 2017 (Temporary …

The report "Global Regenerative Artificial Skin Sales Market Report 2017", has been prepared based on an in-depth market analysis with inputs from industry experts.

This report studies sales (consumption) of Regenerative Artificial Skin in Global market, especially in United States, China, Europe and Japan, focuses on top players in these regions/countries, with sales, price, revenue and market share for each player in these regions, covering

Integra Life Sciences Corporation

Mylan N.V

Johnson & Johnson…