Press release

Automated precision milling in the medical technology sector

Fetzer Medical GmbH & Co. KG employs tailored yet universally flexible Hermle machining centres in its role as an OEM partner manufacturing a wide range of surgical instruments and medical technology components to customer specifications."From the idea to the finished product, or: All-in-one inclusive labelling!" – is the mission statement of Fetzer Medical GmbH & C. KG, a medium-sized company based in Tuttlingen/Germany, which was established in 2008 by Peter Fetzer. In order to build further on the family business' long-standing tradition in the development and manufacture of surgical instruments and medical devices, Peter Fetzer took the decision. With the stated aim of operating exclusively as an independent OEM, establishing all the necessary human and technical resources to that end, Fetzer Medical launched an extensive capital investment, qualification and certification programme, beginning its five-axis machining in 2008. This was rolled out with the stated aim of offering a flexible and swift approach to delivery for varying product and batch sizes. All relevant materials, including titanium, are machined and Fetzer Medical supplies its customers with ready-to-use products - from prototypes/individual parts to large production runs and complete systems. The business currently employs 45 highly-qualified employees and state-of-the-art equipment. Roughly 75 percent of the work involves complex milling/drilling operations which have been performed at Fetzer Medical from day one using high-performance five-axis machining centres from Maschinenfabrik Berthold Hermle AG in Gosheim

From manual single part fabrication to industrial production

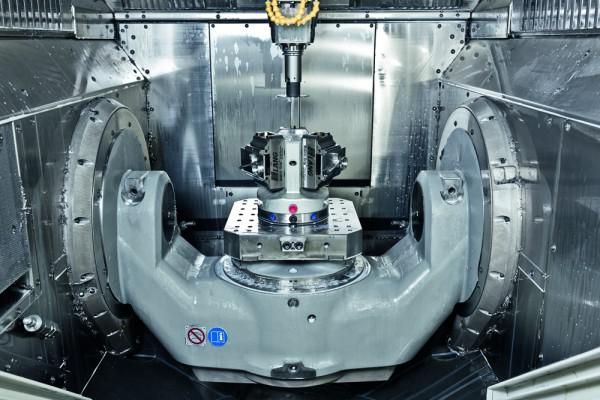

Fetzer Medical production manager Bernd Zepf comments on the choice of Hermle machines: “The Hermle machines featuring a robust gantry design, the machine concept of three axes in the tool and two axes in the workpiece, which results in optimum tool accuracy, and last but not least excellent accessibility are ideal for five-axis complete machining in one or two setups. Further, our employees, including myself, had already had very good experience in the past with Hermle machines: their control and programming, their comparatively simple operator control, including responsive and highly competent service backup. That experience helped us to immediately get started with five-axis technology, which we launched in 2008 by acquiring a Hermle C 40 U high-performance five-axis CNC machining centre.” As the business flourished, capacity had to be increased, and a number of Hermle machining centres – some of them highly automated – were added. Fetzer Medical today runs five machining centres assuring the prompt execution of its OEM production orders. While the first purchased five-axis C 40 U machining centre was initially used to cement the business’ manufacturing expertise and add valuable additional know-how, the machine is now primarily used for pre-fabrication and for machining prototypes, samples and short runs. Additionally, two further C 22 U high-performance five-axis machining centres are equipped with 11-pallet changers/magazines of type PW 150, and are used for the automated flexible production of a wide range of components in runs of up to 300 pieces.

Validated and certified: Production processes on Hermle machining centres

A further automation level includes a C 12 U high-performance five-axis machining centre combined with an RS 05 robot cell for the production of modular designed scissors. A C 800 V CNC machining centre was added to the range of Hermle machines to provide flexible and universal operation in pre-production, including making reference surfaces and jigs and fixtures. Since all the installed Hermle machining centres are essentially based on the same concept and on the same control and operating philosophy, operators are quickly familiarised with running the various machines, and staff confidence and acceptance of the machinery is enhanced as a result. This is definitely advantageous in terms of the productivity of the machines which are run basically in single-shift mode under operator control, though the aforementioned machining centres with the pallets and robot system do of course run overnight and at weekends for automated machine loading. These ‘hard facts’ are complimented by a number of ‘soft facts’ which are essential for the highly complex machining of surgical instruments and medical technology devices. Since – according to specifications of EU and US institutions – production and quality assurance equipment needs to be fully validated and certified in the surgical and medical technology sector, it is a major advantage in terms of US certification that many US medical technology firms use already validated Hermle machining centres for their production lines. This also ensures simpler and faster validation cycles for Fetzer Medical, thus resulting in a faster time-to-market for the company’s customers.

Hermle AG is a well known company with a leading position in national and international markets. Continuous innovations have made Hermle a leading manufacturer of machining centres. More than 25000 users throughout the world trust Hermle machining centres. A close-knit sales and service network guarantees a reliable partner on-site in all

important countries of the world. Hermle machines are produced in Southwestern Germany in a region which has been the home of precision mechanics and machine tools for many generations. Hermle's machining centres are used for efficient machining of tools, moulds and series-produced parts. Owing to their quality and high precision, they are used in numerous production areas, including in particular highly demanding sectors such as medical technology, machine construction, the optical industry, aviation, the automotive and car racing industries and their subcontractors.

www.hermle.de

Contact for enquiries:

Udo Hipp, Head of Marketing, Maschinenfabrik Berthold Hermle AG, D-78559 Gosheim, Germany

Telephone: +49 (0)7426 95-6238

Email: Udo.Hipp@hermle.de

www.hermle.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Automated precision milling in the medical technology sector here

News-ID: 717898 • Views: …

More Releases from Automation

Automation Global Market in Chemicals Petrochemicals Industry Will Reach At A CA …

Researchmoz added Most up-to-date research on "Automation Global Market in Chemicals Petrochemicals Industry Will Reach At A CAGR Of More Than 7% by 2020" to its huge collection of research reports.

Technavios market research analyst predicts the global automation market in the chemicals and petrochemicals market to grow at a CAGR of more than 7% by 2020. The recent rise in capital and R&D investments for automation solutions is a critical…

More Releases for Hermle

Clock Movement Market Behavior Segmentation Opportunities and Emerging Trends 20 …

The Clock Movement Market is an essential component within the horology and timekeeping industry, offering clock movements and mechanisms that drive the hands and timekeeping functions of clocks. These movements are fundamental to the proper functioning of clocks, ranging from traditional analog timepieces to modern digital clocks. The market's significance is highlighted by its role in timekeeping accuracy and precision across various applications, from household and office clocks to industrial…

Clock Movement Market including YOUNG TOWN, Hermle, Kieninger, L'Epee, UTS, Seik …

The Clock Movement market research report is proficient and top to bottom research by specialists on the current state of the industry. This statistical surveying report gives the most up to date industry information and industry future patterns, enabling you to distinguish the items and end clients driving income development and benefit. It centres around the real drivers and restrictions for the key players and present challenge status with development…

Vertical Machining Centers Market Business Opportunities 2025 - Top Companies ar …

We have recently added a report titled 'Global Vertical Machining Centers Market Report' to our extensive database of reports. Our team of experts has curated the report by considering industry-relevant information related to the leading vendors, distributors, and service providers to collect industry-focused insights. We offer to customize our report according to the requirements of our clients.

The authors of the study have derived authentic data relating to the market, to…

Global 3-axis Vertical Machining Centers Market (2019-2025) by Top Manufacturers …

3-axis Vertical Machining Centers Market report provides comprehensive coverage on major industry drivers, restraints, and their impact on market growth during the forecast period. Furthermore, the study encompasses various market specific growth opportunities in 3-axis Vertical Machining Centers market.

A "vertical machining center" has a vertical spindle. With a vertical spindle, tools stick straight down from the tool holder, and often cut across the top of a part.

Get PDF report template…

Global Home Clocks Market 2019 - Howard Miller, Ridgeway Clocks, Hermle, Bulova, …

The Global Home Clocks Market 2019 - overview combining the data integration and analysis capabilities with the relevant findings, the report has predicted strong future growth of the market. The research analyst combining secondary research which involves reference to various statistical databases, relevant patent and regulatory databases and a number of internal a nd external proprietary databases. Cell Line Development Equipment report has focused on each region market…

Hermle machining centre C 22 UP with pallet changer in tool making

With its standardisation strategy and the C 22 UP machining centre from Hermle, the tool and mould making division of the WMF Group has managed to streamline die and tool production processes, thereby creating the scope for services for external customers.

Today, the WMF Group, which was founded in 1853 as Metallwarenfabrik Straub & Schweizer and has been part of the French SEB Group since 2016, represents the best in cooking,…