Press release

Vacuum Packaging Market: Rising Demand for Lower Material Wastage in Packaging to Boost Demand

The vacuum packaging market has witnessed a large number of mergers and acquisitions, leading to a consolidation competitive landscape over the last few years. Most of these activities were undertaken by market leaders in North America and Europe markets, but is still largely fragmented in emerging markets and is witnessing the entry of new players, observes Transparency Market Research in a recent report. A few instances include the January 2016 acquisition of Deluxe Packages by Amcor Limited, the January 2016 acquisition of FIOMO, a.s. by Huhtamaki Oyj. Another instance is the Mondi Group’s March 2015 acquisition of KSP, Co., to increase its footprint in stand-up pouches market.Fill the form to gain deeper insights on this market @ http://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=16151

Transparency Market Research estimates that the revenue generated from the sales of vacuum packaging will be valued over US$15.7 bn by the end of 2016, and increase at a CAGR of 4.9% during 2016-2024. The market’s valuation is expected to surpass US$22.8 bn by 2024. In terms of the material used for vacuum packaging, the polyethylene segment is expected to dominate the market in terms of contribution of revenue over the forecast period. The segment is expected to account for a share of over 38% of the market in 2016. Geographically, the market in Europe is estimated to lead with a 32.4% of the market in 2016.

Rising Trend of Material Minimization to Encourage Usage of Vacuum Packaging

One of the leading drivers for players in the global vacuum packaging market is the increasing demand for packaging that minimizes the waste generated. Currently, close to one-third of the garbage produced every-day in the world consists of packaging. This massive volume of garbage makes for a type of waste that has little or no utilitarian value after a package is opened. Additionally, as a variety of polymers are often used in packaging, dealing with this waste is an increasingly difficult issue owing to the lack of recycling options in most parts of the world. This factor is, in turn, bolstering the demand for vacuum packaging owing to the significantly lower amount of material volume required for vacuum packaging.

With the proper use of vacuum packaging, material minimization can take one step further by reducing the raw materials required to extend the shelf-life of decomposable products such as food and beverages. Since vacuum packaging by itself can considerably add to the lifespan of a product, manufacturers of such products are required to add lesser additional materials to help sustain the quality of the product.

Browse Market Research Report @ http://www.transparencymarketresearch.com/vacuum-packaging-market.html

Rising Preference to Modified Atmosphere Packaging Could Challenge Growth of Vacuum Packaging

A top contender to vacuum packaging in the packaging industry presently is modified atmosphere packaging. Also known as protective gas masks, the MAP process removes most of the air inside a package and replaces it with a mixture of gases that function as a protective agent. The considerably lower cost of MAP packaging as compared to vacuum packaging is leading to an increased preference to the former. MAP is not only affordable to a large number of companies, but also scores high on the scales of shelf-life enhancement and maintaining product quality.

The high cost of vacuum packaging is also one of the market’s key constraints. Cost-sensitive clients prefer other packaging machines due to the high initial capital required for vacuum packaging equipment, despite the greater savings provided in the long run. Vacuum packaging are also highly prone to tears and punctures, especially in the case of thin film packaging. As a result, package handling is a vulnerable area, which could increase the liability of a client towards their customer in terms of product quality management.

About TMR

TMR is a global market intelligence company providing business information reports and services. The company’s exclusive blend of quantitative forecasting and trend analysis provides forward-looking insight for thousands of decision makers. TMR’s experienced team of analysts, researchers, and consultants use proprietary data sources and various tools and techniques to gather and analyze information.

Contact TMR

90 State Street, Suite 700

Albany, NY 12207

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Email: sales@transparencymarketresearch.com

Website: http://www.transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Vacuum Packaging Market: Rising Demand for Lower Material Wastage in Packaging to Boost Demand here

News-ID: 657448 • Views: …

More Releases from Transparency Market Research

Power Lawn and Garden Equipment Market Size Forecast to USD 188.4 Billion by 203 …

Power Lawn and Garden Equipment Market Outlook 2036

The global power lawn and garden equipment market was valued at US$ 93.9 Billion in 2025 and is projected to reach US$ 188.4 Billion by 2036, expanding at a steady CAGR of 6.6% from 2026 to 2036. Market growth is driven by increasing residential landscaping activities, rising demand for battery-powered equipment, expanding commercial landscaping services, and growing consumer interest in outdoor aesthetics.

👉 Get…

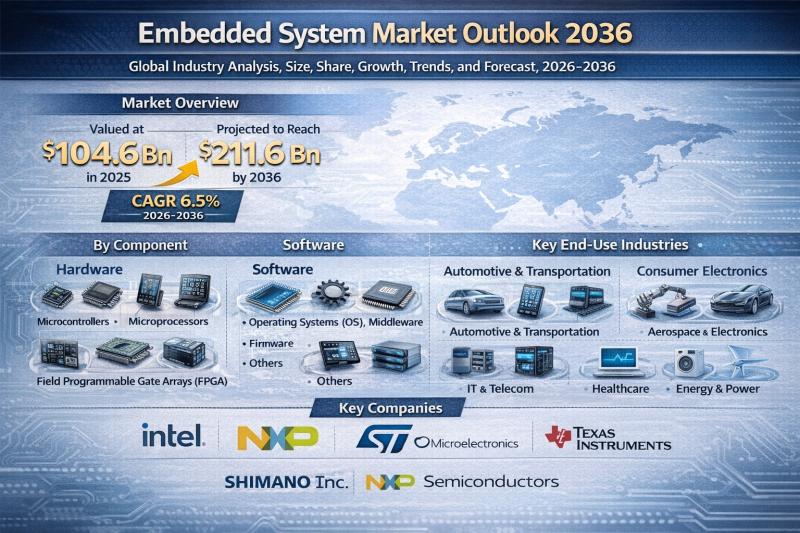

Global Embedded System Market to Reach USD 211.6 Bn by 2036, Expanding at 6.5% C …

The global embedded system market is poised for steady and sustained growth over the next decade, driven by rapid digital transformation across industries. Valued at US$ 104.6 Bn in 2025, the market is projected to reach US$ 211.6 Bn by 2036, expanding at a CAGR of 6.5% from 2026 to 2036. The increasing integration of embedded systems in automotive electronics, industrial automation, and IoT-enabled devices is positioning the industry as…

Industrial Fasteners Market Outlook 2036: Global Industry to Reach US$ 146.5 Bil …

The global industrial fasteners market was valued at US$ 104.6 Bn in 2025 and is projected to reach US$ 146.5 Bn by 2036, expanding at a steady CAGR of 3.1% from 2026 to 2036. The industry reflects consistent, volume-driven growth supported by expanding construction activities, infrastructure modernization, automotive production, and aerospace engineering advancements.

Between 2021 and 2024, the market demonstrated stable recovery post-pandemic, driven by revived industrial production and capital investments…

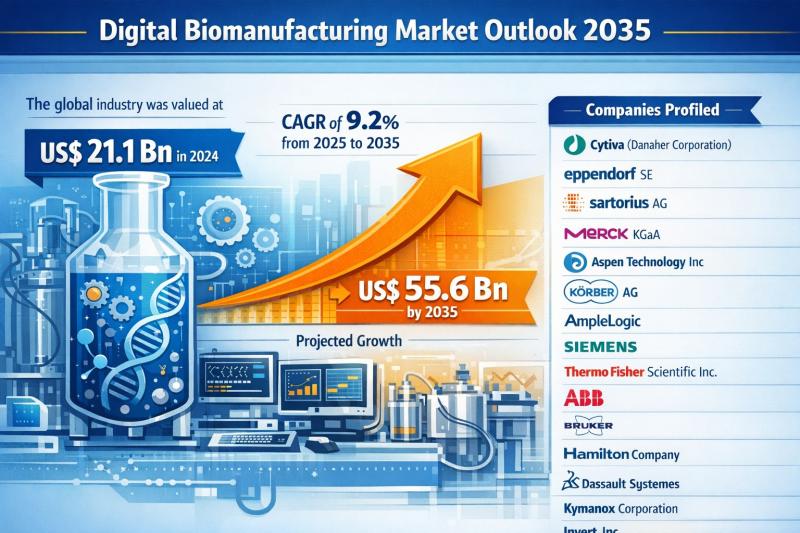

Digital Biomanufacturing Market Outlook 2035: AI-Driven MES, PAT, and Digital Tw …

The global digital biomanufacturing market was valued at US$ 21.1 Bn in 2024 and is projected to expand at a robust CAGR of 9.2% from 2025 to 2035, crossing US$ 55.6 Bn by the end of 2035. The strong double-digit expansion trajectory underscores the accelerating adoption of digital tools across biologics production facilities worldwide.

Between 2020 and 2024, the market witnessed steady adoption, supported by rapid digitalization efforts following pandemic-driven supply…

More Releases for Vacuum

Semiconductor Screw Vacuum Pump Market Industry Trends - Atlas Copco (Edwards Va …

MarketQuest.biz proclaims the addition of another new report titled Global Semiconductor Screw Vacuum Pump Market which is a well-synchronized synopsis of the market. The report offers broad insights extracted by thoroughly analyzing historical and current developments in the market. The report outlines the distinguishable players in the global Semiconductor Screw Vacuum Pump market with a clear-cut end goal to give an intelligent standpoint of the forces of the market, while…

Roots Vacuum Pumps Market SWOT Analysis by Key Players: Pfeiffer, Leybold, ANLET …

Roots vacuum pumps, or vacuum boosters, are dry vacuum pumps that are used together with backing pumps in a wide range of applications where large pumping speeds are required. Vacuum boosters operate completely contact-free and without sealing fluids such as oil or water in the working chamber, although with most models the two gearwheels of the synchromesh gearing and the bearings for the impeller shafts are lubricated with oil. Some…

Vacuum Coating Machines Market 2018 Global Key Country Analysis: Denton Vacuum, …

Vendor Landscape

Tetra Technologies, Inc., (U.S.), BP P.L.C. (U.K.), Statoil ASA (Norway), DNV GL (Norway), TechnipFMC PLC (U.K.), AF Gruppen ASA (Norway), Ramboll Group A/S (Denmark), and Aker Solutions ASA (Norway) are some of the key companies operating in the market. Amec Foster Wheeler (U.K.), John Wood Group Plc. (Scotland), Claxton Engineering Services (U.K.), Allseas group SA (Switzerland), and DeepOcean Group (Netherlands) among others.

Market Research Future’s (MRFR) latest study reveals that…

Global Rotary Vane Vacuum Pumps Market- Pfeiffer Vacuum, Tuthill, Osaka Vacuum, …

Global Rotary Vane Vacuum Pumps Market report 2017 is an in-depth research on the current situation of the Rotary Vane Vacuum Pumps industry.

The Scope of the Rotary Vane Vacuum Pumps research report:

The Global Rotary Vane Vacuum Pumps Market primarily includes a basic overview of the Rotary Vane Vacuum Pumps industry. It also includes Rotary Vane Vacuum Pumps definitions, classifications and applications. It segments the market by applications, types, regions, competitive…

Metallurgical High Vacuum Announces High Vacuum Newsletter

Fennville, MI---Metallurgical High Vacuum has created a new “High Vacuum News” to provide heat treat industry professionals with tips and hints to keep their vacuum pumps running strong.

As Geoff Humberstone, MHV President, comments: “This year marks 30 years for us as Metallurgical High Vacuum. Back in 1981, I saw the need for vacuum design and consulting and started the company. Within four years we added pump remanufacturing because we…

Metallurgical High Vacuum Ships Vacuum Chambers (Corrected)

Special Designs are Built to Customer Specifications

Fennville, MI--- Metallurgical High Vacuum recently shipped two chambers for customer-specific applications. One vacuum chamber is over 72” high and will be used in P E. Chemical Vapor Deposition. The other chamber is a 12-inch square design that will be used to weld silicon sticks, complete with a two-stage booster vacuum pumping system. Both chambers are built of type 304 stainless steel for…