Press release

Aluminum Wire Welding Market Overview, Dynamics and Trends, Segmentation, Key Players 2025

Global Aluminum Wire Welding Market: OverviewWire welding refers to the process of fabricating or shaping a metal wire by assembling, bending, and cutting operations. Therefore, aluminum wire welding is the procedure of joining two or more aluminum wires through fabrication and various sculptural processes. Furthermore, the wires are joined by employing fusion welding techniques which involve melting two or more wires of similar composition. Solid state welding does not involve melting of metals as compared to fusion welding. The coalescence of metals in solid state welding method takes place below the melting point of the base metals being joined to form the wire. This helps the base metals to retain their original properties, thereby preventing the melting of the base metals. Similarly, there are other welding techniques such as diffusion welding, explosion welding, cold welding, and friction welding, which are employed in welding wires.

Browse Market Research Report: http://www.transparencymarketresearch.com/aluminum-wire-welding-market.html

The aluminum welding wire market is driven considerably by the automotive industry. The usage of aluminum by U.S. automakers has been increasing every year since federal fuel economy standards, commonly referred to as Corporate Average Fuel Efficiency (CAFÉ) Standards, were first enacted by the U.S. Congress in the year 1975. Automakers are estimated to increase the usage of aluminum welding wires due to increasing stringent guidelines being dictated by several countries. Aluminum welding wire developments. The developments in aluminum welding wire can be attributed to aluminum’s attractive characteristics such as light weight, high strength, versatility in extrusion and casting, and excellent corrosion resistance. Furthermore, investments in electric power infrastructure is projected to further drive the expansion of the market. The usage of advanced technologies to reduce emission levels, increase fuel efficiency, and improve driving dynamics of the vehicle is increasing in the automotive industry. Therefore, the trend of employing aluminum is anticipated to consequently increase the usage of aluminum welding wires in the automotive industry.

However, aluminum wires get damaged easily and its welding can create porosities. Key challenges posed by welding thin gauge aluminum are distortion, burn-through, and warping. Other common issues related to welding aluminum wire is the feedability of aluminum wire. Aluminum wires are softer and filling the wires with metal fillers through a gun is difficult. These disadvantages of utilizing aluminum in welding wires are key factors that are likely to create a mild negative impact on the expansion of the market.

Use of robots in welding procedures and automation of welding processes is further estimated to propel the expansion of the market. There are several benefits of automating a factory with welding robots to make the process of welding faster, consistent, and with no break in production. Moreover, the usage of welding robots is anticipated to cut down the cost of labor and reduce the incidence of accidents, thereby increasing production. Therefore, these factor are likely to create conducive opportunities for the aluminum wire welding market.

Get accurate market forecast and analysis on the Aluminum Wire Welding market. Request a sample to stay abreast on the key trends impacting this market @ http://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=23663

The global aluminum welding wire market can be segmented into end-users and geography. In terms of end-users, the market can be segmented into shipbuilding, transportation, automotive, domestic use, and others. Usage of aluminum welding wires in the automotive sector can be attributed to the increase in electric car. Continuous R&D activities in this field and increasing preference for environmentally friendly electric cars are projected to make this segment a significant user of aluminum welding wires.

The geographical segmentation includes, North America, Europe, Asia Pacific, Middle East & Africa (MEA), and Latin America. Asia Pacific and North America are expected to hold a considerable share of the global market.

Leading global aluminum wire welding companies operating in this market are ESAB (U.S.), The Lincoln Electric Company (U.S), Air Liquide Welding (U.S.), Drahtwerk ELISENTAL W. Erdmann (U.K.), Novametal (U.S.), and Hermann Fliess and Co. GmbH (Germany).

About Us

Transparency Market Research (TMR) is a global market intelligence company providing business information reports and services. The company’s exclusive blend of quantitative forecasting and trend analysis provides forward-looking insight for thousands of decision makers. TMR’s experienced team of analysts, researchers, and consultants use proprietary data sources and various tools and techniques to gather and analyze information.

TMR’s data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With extensive research and analysis capabilities, Transparency Market Research employs rigorous primary and secondary research techniques to develop distinctive data sets and research material for business reports.

Contact Us

Transparency Market Research

90 State Street, Suite 700

Albany, NY 12207

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Email: sales@transparencymarketresearch.com

Website: http://www.transparencymarketresearch.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aluminum Wire Welding Market Overview, Dynamics and Trends, Segmentation, Key Players 2025 here

News-ID: 632688 • Views: …

More Releases from Transparency Market Research

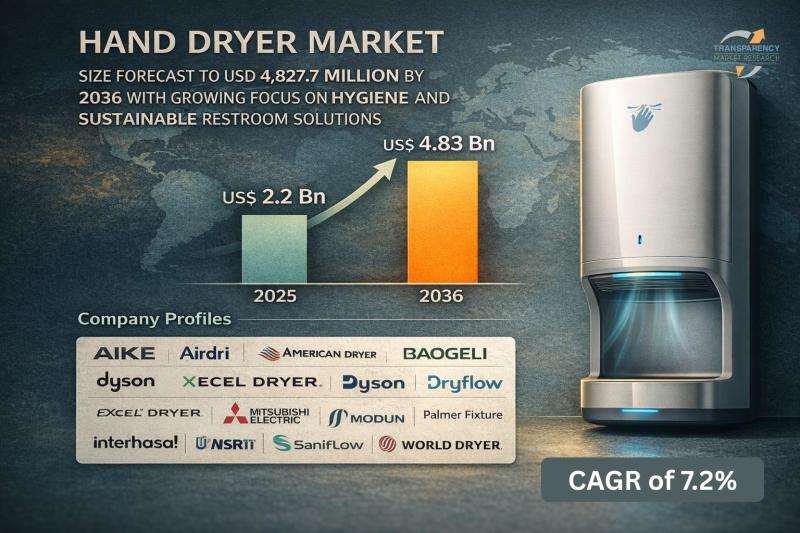

Hand Dryer Market Size Forecast to USD 4.83 Billion by 2036 with Growing Focus o …

Hand Dryer Market Outlook 2036

The global hand dryer market was valued at US$ 2.23 Billion in 2025 and is projected to reach US$ 4.83 Billion by 2036, expanding at a steady CAGR of 7.2% from 2026 to 2036. Market growth is driven by increasing emphasis on hygiene and sanitation, rising adoption in commercial infrastructure, and growing preference for eco-friendly and cost-effective hand drying solutions.

👉 Get sample market research report copy…

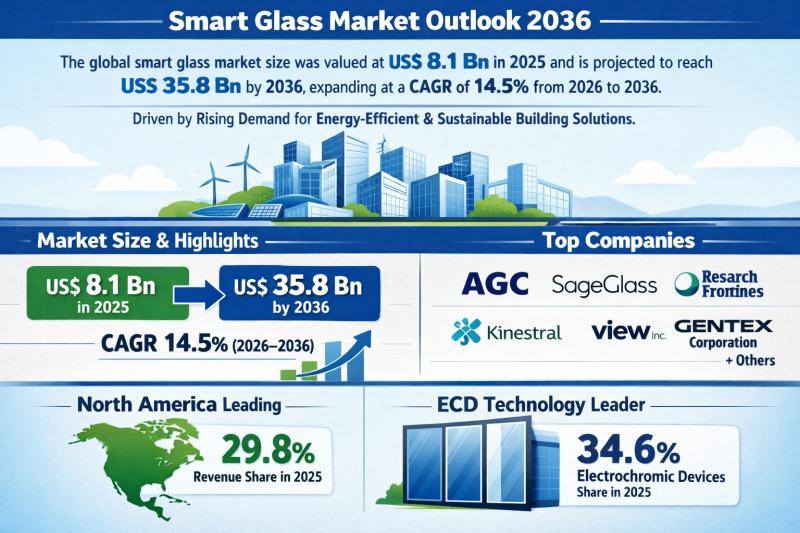

Smart Glass Market Outlook 2036: Projected to Reach USD 35.8 Billion at 14.5% CA …

The global smart glass market was valued at US$ 8.1 Bn in 2025 and is projected to surge to US$ 35.8 Bn by 2036, expanding at a robust CAGR of 14.5% from 2026 to 2036. This nearly 4.4x growth over eleven years underscores the accelerating demand for intelligent glazing solutions across commercial, residential, automotive, and infrastructure sectors.

North America emerged as the leading regional market in 2025, accounting for 29.8% of…

Smoking Cessation and Nicotine De-Addiction Market to Reach USD 46.4 Bn by 2036, …

The global smoking cessation and nicotine de-addiction market is witnessing strong and sustained growth, fueled by intensifying public health initiatives and rising awareness about the long-term consequences of tobacco use. Valued at USD 15.5 Bn in 2025, the market is projected to expand at a robust CAGR of 10.5% from 2026 to 2036, reaching USD 46.4 Bn by 2036.

Smoking cessation solutions encompass a wide range of products and services designed…

3D Imaging Market to be Worth USD 266 Bn by 2036 - By Component Type / By End-Us …

The global 3D imaging market is witnessing exponential growth, reflecting strong demand across healthcare, manufacturing, media, and industrial sectors. Valued at US$ 50 billion in 2025, the market is projected to reach US$ 266 billion by 2036, expanding at a robust CAGR of 18.2% from 2026 to 2036.

Get a concise overview of key insights from our Report in this sample -

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=2743

This impressive trajectory highlights the rapid integration of advanced imaging…

More Releases for Aluminum

New Aluminum Material-Aluminum Foam Application Summary

Aluminum Foam [https://www.beihaicomposite.com/aluminum-foam-tag/] Characteristics

Ultra-lightness

The density is 0.2~0.4g/cm3, which is about 1/10 of the density of aluminum, 1/20 of the density of titaNium, 1/30 of the density of steel, 1/30 of the density of steel, and 1/3 of the density of wood.

Sound Absorbability

Aluminum foam [https://www.beihaicomposite.com/about-us/] can be used to muffle and reduce noise by absorbing sound energy through the vibration of the pores' walls.

Heat resistance

It has high heat resistance; the general…

5083 medium-thick aluminum plate 5083 marine aluminum plate 5083 automotive alum …

5083 aluminum plate(https://www.mingtai-al.com/5083-Aluminum-Sheet.html) is a typical aluminum-magnesium alloy with light weight and high strength. With its excellent performance, it can be widely used in many industries such as automobile manufacturing, shipbuilding and rail transportation. With the vigorous development of lightweight, the demand for 5083 medium-thick aluminum plate in aluminum tank trucks and marine aluminum plates has increased.

5083 medium-thick aluminum plate-5083 marine aluminum plate-5083 automotive aluminum plate manufacturer introduction

In recent years,…

Yocon Aluminum Announces Availability of 3003 Aluminum Coil

Yocon Aluminum, a leading supplier of aluminum coil products in China, today announced the availability of 3003 aluminum coil. The company's new product is made from high-quality, mill-finished 3003 alloy and features excellent formability, weldability, and corrosion resistance. It is ideally suited for a wide range of applications in the transportation, construction, and industrial markets. With its outstanding properties, 3003 aluminum coil is quickly becoming a preferred choice for customers…

Yocon Aluminum china factory offers 3003 Aluminum Coil

Yocon Aluminum china factory is proud to offer 3003 aluminum coil. This high-quality product is perfect for a variety of applications, and we are confident that you will be satisfied with its performance. We are committed to providing our customers with the best products and services possible, and we look forward to helping you meet your needs. Contact us today to learn more about our 3003 aluminum coil!

In an effort…

Yocon Aluminum Supplies Aluminum Foil Coils for Major Appliances

Yocon Aluminum, a leading manufacturer and supplier of aluminum foil coils, has announced that they are now supplying major appliance manufacturers with their high-quality aluminum foil coils. With over forty years of experience in the industry, Yocon Aluminum is known for their dedication to quality and customer satisfaction. Their products are used in a variety of applications, including air conditioners, refrigerators, and freezers. When it comes to choosing a supplier…

Aluminum Frp Market Size, Status and Global Outlook 2021-Shandong Nanshan Alumin …

The MarketInsightsReports has published the obtainability of a new statistical data to its repository titled as, Aluminum Frp market. The comprehensive report provides useful insights into Market growth, revenue, and market trends, in order to enable readers to gauge market scope more proficiently. Furthermore, the report also sheds light on recent developments and platforms, in addition to distinctive tools, and methodologies that will help to propel the performance of industries.…