Press release

Research report covers the Rotomoulding Powder Market share, Size and Growth, 2017-2027

Rotomoulding, also called as rotational moulding is a process used to manufacture plastic moulds without application of pressure as compared to other moulding processes. It is cost effective method and the end products are used to manufacture hollow articles. The major difference between rotomoulding and other method is that plastic or resin powders are used to form the moulds. The rotomoulding powder melts in the mould, which is rotated in biaxial direction. Polyethylene rotomoulding powder accounts for major share in terms of consumption in the global rotomoulding powder market. They are available in different grades, each varying in melt flow and density. Low density polyethylene (LDPE) based rotomoulding powders are used in flexible packaging, moulding, extrusion coating applications. High density polyethylene (HDPE) based rotomoulding powders are used in heavy industrial packaging, telecom ducting, woven sacks, blow moulding etc. The applications of linear low density polyethylene (LLDPE) include insulated containers, automotive components, tanks etc. DuPont, a leading U.S. industrial chemicals manufacture’s product portfolio includes high performance resins with trade name Hytrel. Among the different grades, Hytrel 4056P is used in rotomoulding and are available in powdered form.Rotomoulding Powder Market: Drivers and Restraints

In rotomoulding no pressure is applied and the moulds used are less expensive, hence this method is cost effective method, which is a major driver for the growth of global rotomoulding powder market. The availability of wide variety of rotomoulding powders depending on the requirements of end-use application is expected to boost the consumption of rotomoulding powders. The diverse applications of rotomoulding in industrial packaging, flexible packaging, telecom ducting, blow moulding etc. is anticipated to increase the demand for rotomoulding powders. The availability of rotomoulding powders with advanced features such as UV resistant and flame retardant properties is anticipated to boost the growth of global rotomoulding powders market. The rise in demand for plastic storage tanks is expected to contribute to the growth of rotomoulding powders market.

Request For Report Sample: http://www.futuremarketinsights.com/reports/sample/rep-gb-2601

Rotomoulding Powder Market: Segmentation

On the basis of material,the global rotomoulding powder market can be segmented as follows:-

Polyethylene

Low Density Polyethylene (LDPE)

Linear Low Density Polyethylene (LLDPE)

Medium Density Polyethylene (MDPE)

High Density Polyethylene (HDPE)

PVC Plastisols

Polycarbonate Nylon Polypropylene

On the basis of application,the global rotomoulding powder market can be segmented as follows:-

Consumer Products

Storage Tanks

Automotive Components

Industrial Packaging

Rotomoulding Powder Market: Region Wise Outlook

The global rotomoulding powder market can be divided into seven regions, namely North America, Latin America, Western Europe, Eastern Europe, Asia Pacific Excluding Japan (APEJ), Japan and Middle East and Africa (MEA). Western Europe accounts for major share in global rotomoulding powder market. This is attributed to the strong presence of manufacturing industries in the region. The adoption of rotomoulding technique in manufacturing automotive components and industrial packaging products is expected to drive the growth of rotomoulding powders market in this region. North America contributes a significant share in rotomoulding market, due to increasing demand for plastic based products such as medical equipment and automotive fuel tanks. APEJ is expected to account for major share in global rotomoulding powder market over the forecast period. The increasing demand for water storage and water treatment tanks in emerging economies is anticipated to contribute to the growth of rotomoulding market in the region.

Request For TOC: http://www.futuremarketinsights.com/toc/rep-gb-2601

Rotomoulding Powder Market: Key Players

Some of the key players in the global rotomoulding powder market are as follows:

Broadway Colours

Green Age Industries

PACIFIC POLY PLAST

DuPont

Matrix Polymers

Reliance Industries Limited

A. Schulman, Inc.

PHYCHEM TECHNOLOGIES PVT. LTD.

ABOUT US:

Future Market Insights (FMI) is a leading market intelligence and consulting firm. We deliver syndicated research reports, custom research reports and consulting services, which are personalized in nature. FMI delivers a complete packaged solution, which combines current market intelligence, statistical anecdotes, technology inputs, valuable growth insights, an aerial view of the competitive framework, and future market trends.

CONTACT:

Future Market Insights

616 Corporate Way, Suite 2-9018,

Valley Cottage, NY 10989,

United States

T: +1-347-918-3531

F: +1-845-579-5705

Email: sales@futuremarketinsights.com

Website: http://www.futuremarketinsights.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Research report covers the Rotomoulding Powder Market share, Size and Growth, 2017-2027 here

News-ID: 611098 • Views: …

More Releases from Future Market Insights

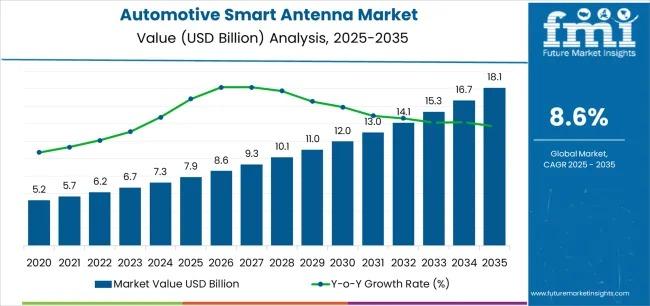

Global Automotive Smart Antenna Market to Reach USD 18.1 Billion by 2035, Driven …

The global automotive smart antenna market is projected to grow from USD 7.9 billion in 2025 to USD 18.1 billion by 2035, registering a robust compound annual growth rate (CAGR) of 8.6% during the forecast period. This expansion reflects the accelerating transformation of the automotive sector toward connected mobility, advanced communication infrastructure, and data-driven vehicle ecosystems. Increasing adoption of 5G-enabled connectivity, advanced driver assistance systems (ADAS), and vehicle-to-everything (V2X) communication…

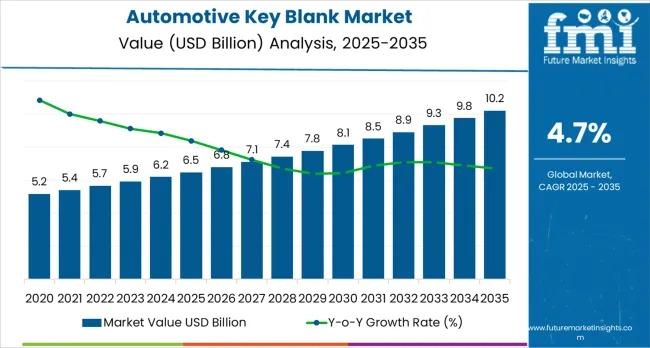

Automotive Key Blank Market to Reach USD 10.2 Billion by 2035 as Smart Key Integ …

The global automotive key blank market is projected to grow from USD 6.5 billion in 2025 to USD 10.2 billion by 2035, reflecting a steady compound annual growth rate (CAGR) of 4.7%. This expansion is being driven by rising vehicle production, increasing adoption of smart and transponder-based security systems, and sustained replacement demand across global automotive fleets. As vehicle access systems evolve toward integrated electronic security frameworks, automotive key blanks…

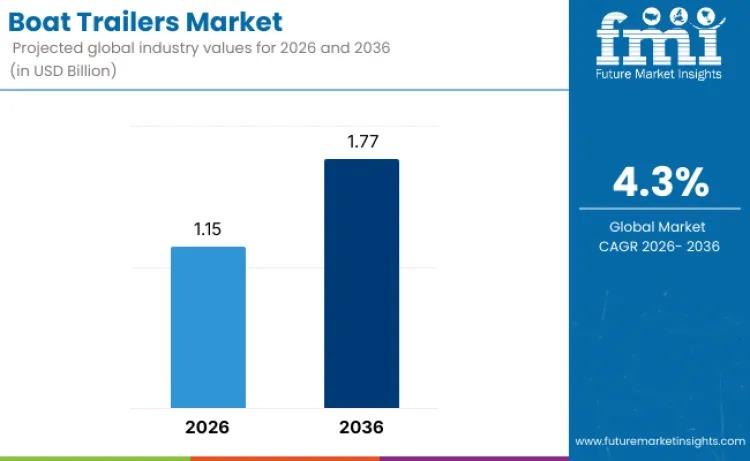

Global Boat Trailers Market to Reach USD 1.8 Billion by 2036 as Recreational Boa …

The global boat trailers market is poised for steady and sustained growth, with industry valuation projected to increase from USD 1.1 billion in 2026 to USD 1.8 billion by 2036, expanding at a compound annual growth rate (CAGR) of 4.3%. This expansion reflects rising global participation in recreational boating, increasing disposable incomes, and expanding investments in marine tourism infrastructure. As water-based leisure activities gain popularity across developed and emerging economies,…

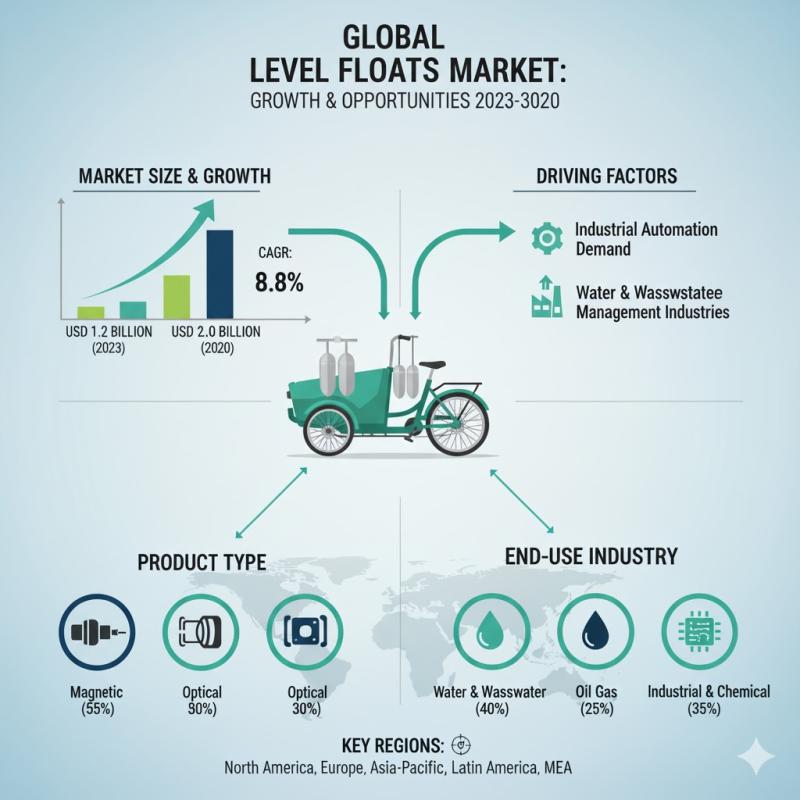

Level Floats Market to Reach USD 461.7 Million by 2035 as Automotive Electrifica …

The global level floats market is projected to grow from USD 311.9 million in 2025 to USD 461.7 million by 2035, registering a steady compound annual growth rate (CAGR) of 4.0% over the forecast period. This expansion reflects rising demand for precision fuel measurement systems across automotive, industrial, and energy applications, supported by increasing vehicle production, evolving fuel management technologies, and stricter regulatory standards focused on efficiency and emissions compliance.

Level…

More Releases for Rotomoulding

Impact of Outbreak of COVID-19 on Rotomoulding Powder Market

Global Rotomoulding Powder Market - Overview

The global rotomoulding powder market has been gathering pace over the years owing to promising rise in demand across industries such as construction, material handling, and automotive. The global rotomoulding powder market is also expected to derive profit in the next few years owing to rising demand for products made with the help of rotomoulding powder in sports activities. This report presents a thorough account…

Rotomoulding Powder Market with Current Trends Analysis, 2018-2026

Global Rotomoulding Powder Market - Overview

The global rotomoulding powder market has been gathering pace over the years owing to promising rise in demand across industries such as construction, material handling, and automotive. The global rotomoulding powder market is also expected to derive profit in the next few years owing to rising demand for products made with the help of rotomoulding powder in sports activities. This report presents a thorough account…

Rotomoulding Powder market Global Forecast over 2017- 2027

Rotomoulding, also called as rotational moulding is a process used to manufacture plastic moulds without application of pressure as compared to other moulding processes. It is cost effective method and the end products are used to manufacture hollow articles. The major difference between rotomoulding and other method is that plastic or resin powders are used to form the moulds. The rotomoulding powder melts in the mould, which is rotated in…

Rotomoulding Powder Market Growth and Forecast 2017-2027

Rotomoulding, also called as rotational moulding is a process used to manufacture plastic moulds without application of pressure as compared to other moulding processes. It is cost effective method and the end products are used to manufacture hollow articles. The major difference between rotomoulding and other method is that plastic or resin powders are used to form the moulds. The rotomoulding powder melts in the mould, which is rotated in…

Rotomoulding Powder Market Value Share, Analysis and Segments 2017-2027

Rotomoulding, also called as rotational moulding is a process used to manufacture plastic moulds without application of pressure as compared to other moulding processes. It is cost effective method and the end products are used to manufacture hollow articles. The major difference between rotomoulding and other method is that plastic or resin powders are used to form the moulds. The rotomoulding powder melts in the mould, which is rotated in…

Rotomoulding Powder Market Expected to Dominate Worldwide by 2027

Rotomoulding, also called as rotational moulding is a process used to manufacture plastic moulds without application of pressure as compared to other moulding processes. It is cost effective method and the end products are used to manufacture hollow articles. The major difference between rotomoulding and other method is that plastic or resin powders are used to form the moulds. The rotomoulding powder melts in the mould, which is rotated in…