Press release

BOMAG: The starter’s gun has sounded to construct the most modern drum plant in the world

BOMAG, global market leader in compaction technology, has announced that it is going to build the world's most modern roller drum facility, signalling a further expansion of the main factory in Boppard. In future, manufacturing, assembly and painting of all drums will be carried on a site area of 11,500 m2. The project will cost around 24 million Euros, making it the largest single investment in the 51 year history of the company."Over the last few years BOMAG has enjoyed tremendous growth. In just four years our turnover has grown from 401 million Euros in financial year 2004 to 634 million Euros in 2007. That is over 50 percent," says Ralf Junker, Production Manager at BOMAG. "Although we also have plants in Italy, the USA and China, we are focusing on increasing production in Boppard as well. We have now reached the limit of our capacity here. We must expand."

The company will also be winding-up its 2008 financial year with outstanding results. In spite of a declining US American market and the economic slow-down in Western Europe, BOMAG will use the new plant to prepare for further growth in the booming markets of Eastern Europe, Asia, Africa and the Middle East.

One aspect of the investment includes the expansion of the Boppard site with the purchase of a neighbouring 12,000 m2 property. Construction will begin on the new drum plant at the beginning of 2009, and the production start is planned for early 2010.

The completion in 2010 will see BOMAG’s current capacity doubled. An independent plant within a plant - over an area of 11,500 m2: a production centre operating in response to customer orders using the latest energy saving, efficiency, ergonomic and workplace design methods. Including, for example, heat recovery systems, a photovoltaic system for generating electricity, innovative production technology, clean-room assembly and process optimisation.

Whereas current production areas are located apart from each other, the new plant will consolidate everything onto one site. This will reduce in-house plant traffic; allow storage of materials close to assembly and reduce the use of forklifts. State-of-the-art logistics for material handling and supply, greater use of robots and driverless transport systems, and a high level of automation will reduce costs and increase BOMAG’s competitiveness over the long-term.

Nevertheless, in spite of all the automation, the focus of the new factory is still people-oriented. Production is based on the principle of group work and the principles of individual responsibility and freedom to make decisions for each employee. The short routes between areas are driven by the need to have materials in close proximity. Robots will carry out less-pleasant work such as washing or spray-painting drums. The increasing automation takes the pressure off staff but does not lead to less employment. On the contrary, once the last expansion phase is reached, the new plant will employ 160 staff. That's 50 workplaces more than today.

Ralf Junker summarises the project as follows: "This new plant means we can increase our capacity and the quality of our products. We will also optimise our cost structures, raise the quality of workplaces and create more flexibility for our customers and suppliers. It's an important building block for our future."

BOMAG is a global market leader in the field of compaction technology. The company, which is situated in Boppard and has belonged to the FAYAT Group since 2005, produces machines for soil, asphalt and refuse compaction as well as stabilizers/recyclers, milling machines and finishers.

In 2007, around 2,000 employees throughout the world achieved a turnover of 634 million Euros. The company owns six branches within Germany and 11 subsidiary companies. More than 500 dealers in over 120 countries guarantee global distribution of BOMAG machines and their service.

BOMAG GmbH

Dr Iris v. Kirschbaum

Head of Communications

Tel: +49 6742 / 100-232

Fax: +49 6742 / 100-109

Email: iris.kirschbaum@bomag.com

URL: http://www.bomag.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release BOMAG: The starter’s gun has sounded to construct the most modern drum plant in the world here

News-ID: 53279 • Views: …

More Releases from BOMAG GmbH

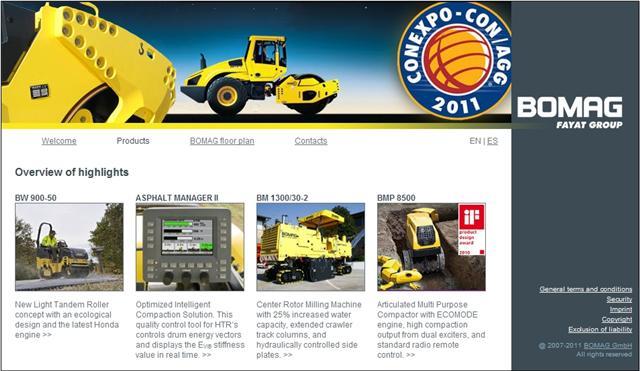

CONEXPO Show in Las Vegas: BOMAG informs on its highlights

Construction equipment manufacturer BOMAG informs on its highlights at the 2011 CONEXPO Show in Las Vegas on a special website ( www.bomag.com/conexpo ). Apart from short product introductions and a selection of photos the website offers downloads such as data sheets and leaflets as well as a floor plan and a contact sheet. The products highlights featured on the website are the light tandem roller BW 900-50, the multipurpose compactor…

More Releases for Boppard

C-Reactive Protein Test (Crp) Market to Witness Huge Growth by Key Players: Wanf …

The C-Reactive Protein Test (Crp) report compiles the market information depending upon market development and growth factors, optimizing the growth path. In addition, it highlights the strategies and market share of the leading vendors in the particular market. The report follows a robust research methodology model that helps to make informed decisions. It obtains both qualitative and quantitative market information supported by primary research.

The C-Reactive Protein Test (Crp) research report…

Herbert Piel, renowned reportage photographer, joins the elite group of ILFORD M …

Herbert Piel, renowned reportage photographer, joins the elite group of ILFORD Masters. The ILFORD Masters are eminent photographers from around the world, that use ILFORD GALERIE to present their work. Herbert Piel is the twenty-eighth ILFORD Master and joins Manuel Thome as one of the two Germans represented (Detail information ILFORD Masters: http://ilford.com/community/ilford-masters).

“The ILFORD Masters is a very prestigious group of photographers that lead the way in their particular…

Official start signal for the IVU.suite

Contract signed for the introduction of the ITCS solution in Rhineland-Palatinate

After IVU Traffic Technologies AG won the European call for tenders issued by Rhenus Veniro Süd-West for the introduction of an ITCS system, all the participants met on Friday in Bad Kreuznach to officially sign the contract. The Bad Kreuznach Public Transport company (VGK) is one of the first bus companies whose vehicles are to go into operation with IVU…

CONEXPO Show in Las Vegas: BOMAG informs on its highlights

Construction equipment manufacturer BOMAG informs on its highlights at the 2011 CONEXPO Show in Las Vegas on a special website ( www.bomag.com/conexpo ). Apart from short product introductions and a selection of photos the website offers downloads such as data sheets and leaflets as well as a floor plan and a contact sheet. The products highlights featured on the website are the light tandem roller BW 900-50, the multipurpose compactor…