Press release

Cost reduction with a state-of-the-art central vacuum system

British American Tobacco (BAT) produces cigarettes and other tobacco products at its plant in Bayreuth, Germany. Two central vacuum systems provide vacuum used for retaining, handling and packaging at different machines throughout the entire production process. In the course of energy conservation measures, both vacuum systems have now been inspected to check their energy efficiency and one of them was equipped with new Mink claw vacuum pumps from Busch. This resulted in considerable energy savings and significantly reduced maintenance.During three-shift operation with 1,400 employees in a highly automated production process, BAT manufactures 200 million cigarettes each day in Bayreuth for over 30 different brands. 36 percent of cigarette production is for the German market. The rest is exported to other, mostly European, countries.

The most state-of-the art cigarette machines achieve a capacity of 20,000 cigarettes per minute, which in turn corresponds to 1,000 packages. All processes within this high-performance unit are computer-controlled and networked with each other. The high degree of automation and high production speed require reliable vacuum supply wherever a part has to be held or moved during the production process. This starts when an individual cigarette is held during its production, and continues through to external packaging in boxes for delivery.

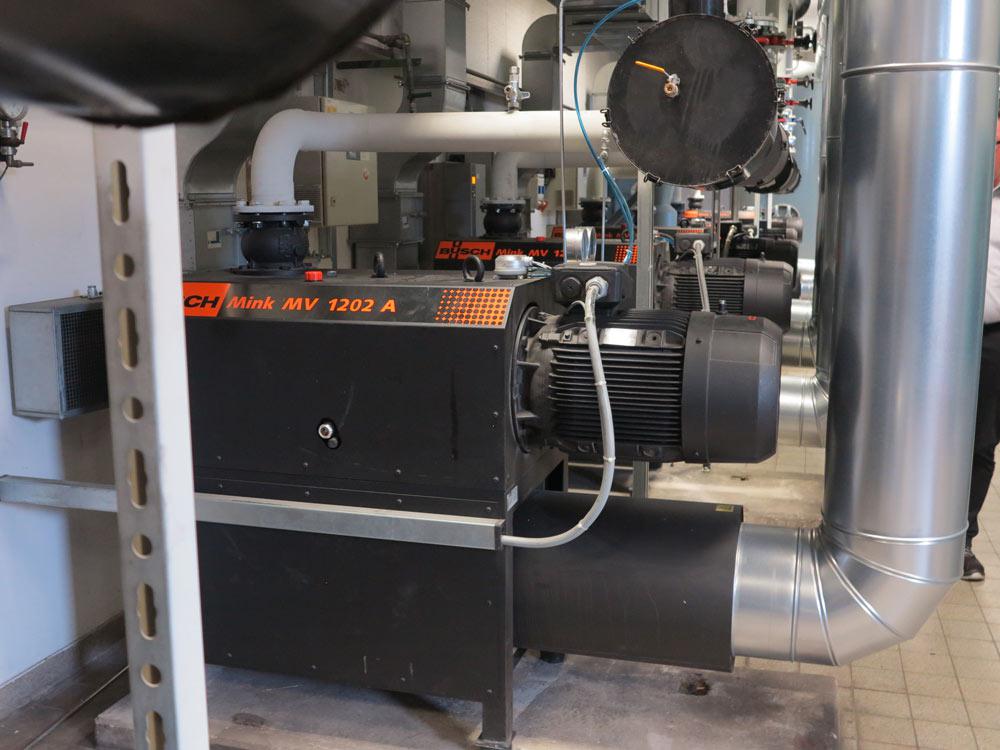

Due to the size of the production facility with a length of over 600 meters, two central vacuum systems were installed. One of the systems is operated with liquid ring vacuum pumps, the other was equipped with oil-lubricated rotary vane vacuum pumps. Both systems were checked for energy consumption and efficiency. Busch Vacuum Pumps and Systems recommended the new Mink MV claw vacuum pump as a replacement for the previous central system with oil-lubricated rotary vane vacuum pumps. The claw vacuum pumps achieve a pumping speed of up to 1200 cubic meters per hour.

The first tests with this kind of vacuum pump were extremely successful for BAT.

Since mid-2015, the new central vacuum system is in operation with a total of seven Mink MV claw vacuum pumps. The pumping speed of the vacuum system is controlled as required. That means that individual vacuum pumps shut off automatically when their output is not required. Two of the Mink MV claw vacuum pumps are driven by a variable speed drive. The actual pumping speed demanded is finely adjusted with both of these vacuum pumps, which ensure that the required vacuum of 370 millibar is permanently and constantly applied at all connected machines.

A Mink MV with a 50-Hz standard motor with 18.5 kilowatts generally achieves a 1000 cubic meter per hour pumping speed. A rotary vane vacuum pump with comparable output is driven by a 30 kilowatt motor. The current consumption of the Mink claw vacuum pumps is smaller by 11.5 kilowatts and translates to cost savings of over EUR 9,000 per year and per pump under BAT operating conditions. For the entire central system, this translates to yearly electricity cost savings of approximately EUR 63,500. This calculation assumes that the central vacuum system is running 100 percent at full load. This is not usually the case, which means that electricity costs can actually be estimated even lower.

In practice, the new Mink MV central vacuum system at BAT has an additional advantage that is decisive: Mink claw vacuum pumps are virtually maintenance free. With the oil-lubricated rotary vane vacuum pumps, oil had to be changed twice each year because dust sucked into the vacuum pumps mixed with the oil and was deposited on the oil separators. Each time the oil was changed, it was also necessary to change all filter elements in the vacuum pumps. In addition, once a year a large inspection had to be performed during which all seals and wearing parts were replaced. The service life of the vanes was limited to two years due to abrasive dust.

Now the incidental dust is sucked up by the Mink claw vacuum pumps and discharged again. This does not damage the vacuum pumps. Maintenance is limited to a yearly inspection performed by Busch service technicians. In the process, the oil in the gearbox is changed as a preventative measure. This minimum maintenance effort is possible because of the operating principle of Mink vacuum pumps. Due to the complete elimination of oil in the compression chamber, there is no contact between the intake air and the operating fluid. All oil-related maintenance is thus eliminated, such as oil checks, oil changes, topping up the oil and exchange of oil filters and other filter elements. The costs for this work and procurement of oil and filter elements and their disposal are completely eliminated. This made it possible to reduce maintenance costs by approximately EUR 9,600 per year for all seven vacuum pumps.

BAT in Bayreuth is certified according to ISO 50001 and was able to reduce energy consumption by 34 percent from 2005 to 2014 and CO2 emissions by 38 percent. Due to the new central vacuum system, these values will continue to develop positively, particularly in the next step when the existing old vacuum system with liquid ring vacuum pumps is also to be replaced with Mink MV claw vacuum technology.

Busch Vacuum Pumps and Systems is one of the largest manufacturers of vacuum pumps, blowers and compressors in the world.

With a lot of experience and top qualified personnel, we are forward-looking and strive to improve our products and ourselves. We are constantly at work developing innovative technologies that will define the vacuum world of the future.

Our manufacturing plants utilize the most modern manufacturing techniques, machinery and equipment under very strict quality controls, which surpass DIN EN ISO 9001 requirements.

As of 2016, Busch Vacuum Pumps and Systems employs more than 3000 people and features the largest selection of vacuum pumps for the industrial applications in the world. Due to its immense line of vacuum pumps, expertise and experience in the building of vacuum systems and the extensive service network, Busch is capable of providing ideal comprehensive solutions.

With 60 companies in 42 countries and sales agents in over 30 countries, we are strategically positioned throughout the world to provide our customers with the essentials for success.

Our goal always is to provide the customer with the highest possible return on investment. Personal consulting, choice of the optimum product and prompt service on site are key features of our comprehensive service that make the achievement of this goal reality. Our experience and know how in broadly diversified applications and product design furnish the basis.

Busch’s headquarter is located in Maulburg, Germany. Besides Busch Holding, the German manufacturing plant, Busch Produktions GmbH, the sales organization, Dr.-Ing. K. Busch GmbH and service company, Busch Dienste GmbH are headquartered here. In addition, Busch operates production plants in Switzerland, Great Britain, Czech Republic, Korea and the USA.

Head of Marketing Services

Uli Merkle

uli.merkle@busch.de

Busch Dienste GmbH

Schauinslandstraße 1

79689 Maulburg

Germany

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Cost reduction with a state-of-the-art central vacuum system here

News-ID: 484721 • Views: …

More Releases from Busch Dienste GmbH

Liquid ring vacuum pumps – Classic vacuum technology and yet still state of th …

Vacuum technology has never stopped developing – not only in the recent past, but for decades it has continued to progress. Today, dry screw vacuum pumps are used in chemical processing technology and many other applications just as dry claw vacuum pumps have established themselves as standard vacuum generators in entire branches of industry. Oil-lubricated rotary vane vacuum pumps are also state of the art in many applications, not least…

Proven vacuum technology fit for Industry 4.0

Busch Vacuum Pumps and Systems enjoyed a great deal of interest from an audience of experts at the IFFA in Frankfurt. The vacuum technology specialist showcased its latest products for the vacuum packaging of meat and sausage products and for meat processing.

Busch also premiered the new R 5 PLUS rotary vane vacuum pump, which is prepared for Industry 4.0. This innovative vacuum pump is based on proven rotary vane vacuum…

Busch solutions for Industry 4.0 at ComVac

The Busch Vacuum Pumps and Systems trade show appearance received a great response from visitors to ComVac, the leading international trade show for compressed air and vacuum technology, held in Hanover, Germany. The interested trade show crowds were able to discover the topic of Vacuum 4.0 and the best-fitting innovative vacuum solutions at Busch.

Numerous visitors took the opportunity to talk to the Busch vacuum experts. With Vacuum 4.0, Busch is…

Dry vacuum systems for centralization of vacuum supply

The concept, design and realization of central vacuum supplies is one of Busch Vacuum Pumps and Systems' core competencies. Thousands of such vacuum systems are in operation worldwide. A wide range of operating principles for generating vacuum in the individual pump modules are applied. In addition to oil-lubricated R 5 rotary vane vacuum pumps, dry-compressing vacuum modules can be used, for example in vacuum systems with COBRA NX screw vacuum…

More Releases for Mink

Mink Oil Market is Booming Worldwide with a CAGR of 4.2%

The "Global Mink Oil" intelligence report, just published by USD Analytics, covers insurers' micro-level study of important market niches, product offers, and sales channels. To determine market size, potential, growth trends, and competitive environment, Global Mink Oil provides dynamic views. Both primary and secondary sources of data were used to generate the research, which has both qualitative and quantitative depth. Several of the major figures the study featured Touch of…

Mink Oil Market Expected To Witness a Sustainable Growth Over 2031

Mink Oil market is estimated to attain a valuation of US$ 31.70 Mn by the end of 2031, states a study by Transparency Market Research (TMR). Besides, the report notes that the market is prognosticated to expand at a CAGR of 4.7% during the forecast period, 2021-2031

𝐆𝐞𝐭 𝐚 𝐒𝐚𝐦𝐩𝐥𝐞 𝐂𝐨𝐩𝐲 𝐨𝐟 𝐭𝐡𝐞 𝐌𝐢𝐧𝐤 𝐎𝐢𝐥 𝐌𝐚𝐫𝐤𝐞𝐭 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐑𝐞𝐩𝐨𝐫𝐭 (𝐔𝐬𝐞 𝐂𝐨𝐫𝐩𝐨𝐫𝐚𝐭𝐞 𝐌𝐚𝐢𝐥 𝐈𝐝 𝐟𝐨𝐫 𝐐𝐮𝐢𝐜𝐤 𝐑𝐞𝐬𝐩𝐨𝐧𝐬𝐞) -

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=32039

"Connect with our team of research…

Key Trends in Mink Oil Market to Partake Significant Development during 2031

The global Mink Oil market is estimated to attain a valuation of US$ 31.70 Mn by the end of 2031, states a study by Transparency Market Research (TMR). Besides, the report notes that the market is prognosticated to expand at a CAGR of 4.1% during the forecast period, 2021-2031.

The key objective of the TMR report is to offer a complete assessment of the global market including major leading stakeholders…

Future Growth Mink Oil Market Sees Promising Growth in 2031

The global Mink Oil market is estimated to attain a valuation of US$ 31.70 Mn by the end of 2031, states a study by Transparency Market Research (TMR). Besides, the report notes that the market is prognosticated to expand at a CAGR of 4.1% during the forecast period, 2021-2031.

The key objective of the TMR report is to offer a complete assessment of the global market including major leading stakeholders…

Mink Oil Market to Evolve In Near Future 2027 According to Industry Report | By …

Mink oil is an oil utilized in clinical and restorative items. It is acquired by the delivery of mink fat which has been eliminated from pelts bound for the hide business. Mink oil is a wellspring of palmitoleic corrosiveness, which has actual properties like human sebum.

Prime players of the Mink Oil market:

Touch Of Mink

Spec Environment Solution

Pfau Oil

Fitohim Farm Llc

Mink Seal Company

Aili Inc

Mosselman

,& Others.

Grab Your Sample Report @

https://www.infinitybusinessinsights.com/request_sample.php?id=608074

In this report…

Mink oil Market- Valuable Growth Prospects And Insights On Future

Overview

The business intelligence report from TMR is an all-important tool that enables vendors to discover growth opportunities, and undertake strategic planning to tap into these opportunities. The valuable facts, figures, and statistical information provided is compiled based on extensive primary and secondary research and insightful inputs received by industry experts.

Obtain Report Details @ https://www.transparencymarketresearch.com/mink-oil-market.html

Market Insights

The market research study from TMR discusses the demand drivers, geographical distribution, and competitive scenario of…