Press release

Perfect surface properties through fluorination using modern vacuum technology

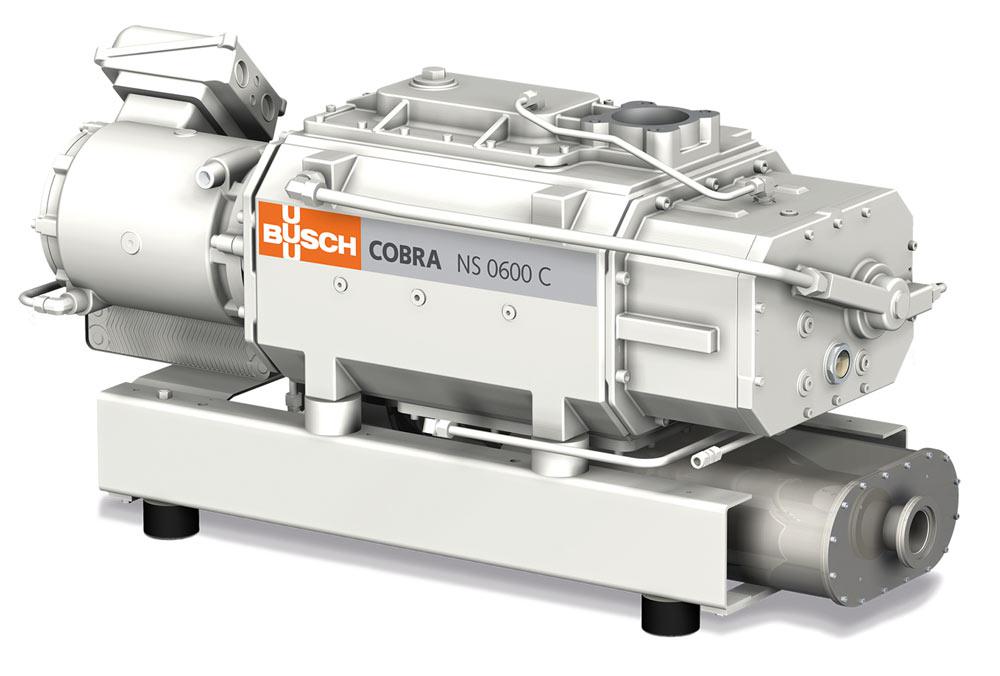

The fluorination of plastic parts to achieve different surface properties is an important pre-treatment step in the processing of plastic parts. Fluor Technik System GmbH has developed a specialization in this type of surface treatment. As a service provider, the company offers fluorination of plastic parts to change the wetting behaviour, the adhesion properties, the friction or stickiness and the barrier properties of a variety of plastics. Fluor Technik System also manufactures customer-specific fluorination systems and sells these worldwide. To generate the necessary process vacuum, dry-compressing vacuum systems from Busch are installed, each with a COBRA NS screw vacuum pump as a backing pump. This has been selected as it provides the most reliable option for Fluor Technik System to run the fluorination process safely and in a replicable way.For around 25 years now, Fluor Technik System has been manufacturing fluorination systems in the German city of Lauterbach in Hesse that are configured to its customers' individual needs. This tailored approach does not just apply to the hardware itself. The control system that can be used to call up the different programs is also adapted in line with the parts that the customer wants to fluorinate. Fluor Technik System installs the systems worldwide and commissions them using its own technicians. As a service provider, the company also offers the fluorination of plastic, rubber and silicone parts. The firm's customers come from a huge variety of sectors, and thus parts for the automotive industry and its suppliers, medical technology, aerospace technology and "white goods" are all pre-treated using fluorination.

The type of fluorination the company performs most often is adhesion fluorination. This process enables a plastic surface to be influenced in such a way that a higher polarity is obtained, the total contact area of the surface is increased as a result and better adhesion is therefore possible. This might be necessary, for example, if different layers need to be bonded at the same time, or to prepare a surface for painting or flocking, or to improve the adhesion of glue. The fluorination process is also used for hydrophilization. With this process, surfaces are equally wetted, which in turn facilitates printing or, for example, in the case of dishwasher applications, makes them easier to dry. Fluor Technik System has the capability to fluorinate nearly all plastics to minimize dynamic friction. The company can also draw on extensive experience in the fluorination of rubber and silicone.

The fluorination process can be carried out within different systems. These either consist of a process chamber, loaded with a batch each time (offline systems), or web systems, with which plastic web material is continuously fluorinated as it passes through (inline systems). A gas mixture comprising 10%fluorine and 90%oxygen is used as the fluorinating agent. The change in the surface properties is caused by the highly reactive fluorinated gas. This replaces a portion of the hydrogen atoms in the surface material with fluorine atoms. The fluorination process is therefore a chemical reaction and not a type of coating. The depth of penetration of the fluorine atoms into the substrate is confined to the molecular level. The properties of the base material and its dimensions remain completely unchanged. Only the surface energy and the polarity are influenced by the fluorine, and these effects are lasting and stable. Through targeted process control, the fluorination results can be precisely adjusted to the base polymer and the intended application. The basic process parameters are the dwell time in the process chamber, the temperature, and the fluorine concentration, which is determined by the pressure. These parameters enter into the fully automatic process control as a "prescription". All the parts to be fluorinated therefore receive an individual "prescription" that is tailored to the base material and the intended surface property as part of a process that is always replicable.

"The core component of a fluorination system is the vacuum technology," says Bernd Moeller, Managing Director of Fluor Technik System. "The is because the quality of the treated parts depends on the reliability of this technology." In his fluorination systems, he only uses vacuum systems from Busch that can be run completely "dry"; that is, without any operating fluids in the compression chambers. A COBRA NS screw vacuum pump is used as a backing pump and a Panda vacuum booster is installed upstream of this.. COBRA NS screw vacuum pumps were developed by Busch for the semiconductor industry. They offer a high level of process reliability and thanks to their optimized screw profile, they achieve short evacuation times. COBRA NS screw vacuum pumps are hermetically sealed and therefore no fluorinated gas can escape into the surrounding area.

Both vacuum pumps, including the drives, are water cooled, which means that the operating temperature can be precisely adjusted. Various monitoring devices report any faults that might occur as soon as they are present. The temperatures of the vacuum pumps themselves, the operating fluid in the gears and the coolant temperature are constantly measured as part of this. The quantities of coolant and oxygen used to rinse the COBRA NS once the process has finished is also monitored.

Bernd Moeller has thoroughly tested the vacuum system from Busch and is utterly convinced that it represents a robust and reliable solution. The vacuum systems are in operation between 8 and 24 hours, depending on the applicable working hours. The gears of the COBRA NS screw vacuum pumps and the gears of the Puma vacuum boosters are lubricated with perfluorinated polyethers. This ensures that the reactive fluorine cannot bond with the operating fluid. In the case of vacuum reactors that are rectangular in shape, gas circulation is required within the process chamber in order to ensure that it fills all areas completely and evenly and to guarantee homogeneous surface processing. Water-cooled Puma vacuum boosters are also used in this process and are operated independently from the vacuum system.

Fluor Technik Systeme receives the vacuum systems that are individually adapted to the relevant fluorination systems from Busch ready for connection and installs them together with the whole system directly at the client's premises. In addition to the technical advantages of the vacuum systems, Bernd Moeller also identifies a further key benefit from collaborating with Busch: After the fluorination systems are installed, these are commissioned by Busch's own technicians and the personnel who will be operating and maintaining the systems are provided with on-site training. Because Busch has a worldwide network of companies operating in their individual countries and forming a tightly knit service network, it is able to provide a local Busch service technician for start-up and training to explain the vacuum system to the customer. Service technicians can also offer maintenance for the customer's vacuum system.

Busch Vacuum Pumps and Systems is one of the largest manufacturers of vacuum pumps, blowers and compressors in the world.

With a lot of experience and top qualified personnel, we are forward-looking and strive to improve our products and ourselves. We are constantly at work developing innovative technologies that will define the vacuum world of the future.

Our manufacturing plants utilize the most modern manufacturing techniques, machinery and equipment under very strict quality controls, which surpass DIN EN ISO 9001 requirements.

As of 2016, Busch Vacuum Pumps and Systems employs more than 3000 people and features the largest selection of vacuum pumps for the industrial applications in the world. Due to its immense line of vacuum pumps, expertise and experience in the building of vacuum systems and the extensive service network, Busch is capable of providing ideal comprehensive solutions.

With 60 companies in 42 countries and sales agents in over 30 countries, we are strategically positioned throughout the world to provide our customers with the essentials for success.

Our goal always is to provide the customer with the highest possible return on investment. Personal consulting, choice of the optimum product and prompt service on site are key features of our comprehensive service that make the achievement of this goal reality. Our experience and know how in broadly diversified applications and product design furnish the basis.

Busch’s headquarter is located in Maulburg, Germany. Besides Busch Holding, the German manufacturing plant, Busch Produktions GmbH, the sales organization, Dr.-Ing. K. Busch GmbH and service company, Busch Dienste GmbH are headquartered here. In addition, Busch operates production plants in Switzerland, Great Britain, Czech Republic, Korea and the USA.

Uli Merkle

Head of Marketing Services

Telephone: +49 (0)7622 681-144

E-Mail: Uli.Merkle@busch.de

Website: www.buschvacuum.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Perfect surface properties through fluorination using modern vacuum technology here

News-ID: 469221 • Views: …

More Releases from Busch Dienste GmbH

Liquid ring vacuum pumps – Classic vacuum technology and yet still state of th …

Vacuum technology has never stopped developing – not only in the recent past, but for decades it has continued to progress. Today, dry screw vacuum pumps are used in chemical processing technology and many other applications just as dry claw vacuum pumps have established themselves as standard vacuum generators in entire branches of industry. Oil-lubricated rotary vane vacuum pumps are also state of the art in many applications, not least…

Proven vacuum technology fit for Industry 4.0

Busch Vacuum Pumps and Systems enjoyed a great deal of interest from an audience of experts at the IFFA in Frankfurt. The vacuum technology specialist showcased its latest products for the vacuum packaging of meat and sausage products and for meat processing.

Busch also premiered the new R 5 PLUS rotary vane vacuum pump, which is prepared for Industry 4.0. This innovative vacuum pump is based on proven rotary vane vacuum…

Busch solutions for Industry 4.0 at ComVac

The Busch Vacuum Pumps and Systems trade show appearance received a great response from visitors to ComVac, the leading international trade show for compressed air and vacuum technology, held in Hanover, Germany. The interested trade show crowds were able to discover the topic of Vacuum 4.0 and the best-fitting innovative vacuum solutions at Busch.

Numerous visitors took the opportunity to talk to the Busch vacuum experts. With Vacuum 4.0, Busch is…

Dry vacuum systems for centralization of vacuum supply

The concept, design and realization of central vacuum supplies is one of Busch Vacuum Pumps and Systems' core competencies. Thousands of such vacuum systems are in operation worldwide. A wide range of operating principles for generating vacuum in the individual pump modules are applied. In addition to oil-lubricated R 5 rotary vane vacuum pumps, dry-compressing vacuum modules can be used, for example in vacuum systems with COBRA NX screw vacuum…

More Releases for COBRA

ATEQ & Cobra Aviation Welcome New Business Development Manager, David Barringer

ATEQ & Cobra Aviation, Inc. is proud to announce the addition of new Business Development Manager, David Barringer, to our team to grow ATEQ’s market share and create new business relationships and strategic partnerships with OEM manufacturers, airlines and part 145 repair stations across the United States.

Barringer comes to ATEQ with 19 years of experience as an aircraft avionics technician with USAF, Raytheon and L3 Communications. He also gained 6…

ATEQ Aviation and Cobra Systems Welcome Susan Johnson

ATEQ Aviation and Cobra Systems are happy to welcome new Product Specialist, Susan Johnson. Susan will handle inside sales for Cobra Systems and work closely with ATEQ's marketing coordinator, Heidi Franklin, on communication initiatives.

"I am thrilled to have someone on board with years of communications experience to assist me with marketing the new ATEQ-Cobra brand," said Franklin.

Susan's entire career has been in the aviation industry which began with obtaining her…

Cell Line Development Market – Performance survey 2028 | Cobra Biologics, Path …

Global Cell Line Development Market: Overview

The report details an exhaustive account of the global cell line development market along with numerous associated factors. Some of these factors that are included in the report are drivers, restraints, competitive analysis, latest trends and opportunities, geographical outlook, and many other aspects. The study covered in the report spans a forecast period from 2018 to 2028. From an overall perspective, the report is expected…

Legal Process Outsourcing Services Market Competitive Analysis 2017-2025 : Clutc …

Global Legal Process Outsourcing Services Market: Snapshot

The wave of outsourcing has swept across a wide spectrum of industries world over, and the law industry is no different. The key motivations for outsourcing in various sectors has been cost-savings and reduced risk factors in the backdrop fiercely competitive landscape. Adoption of legal process outsourcing (LPO) services has enabled the players in the industry to embark on cost-saving measures while focusing on…

ATEQ and Cobra Systems Welcome Krystle Abbott

ATEQ Aviation, along with Cobra Systems, is pleased to announce the addition of a new Office Manager, Krystle Abbott. Cobra Systems, located just outside of Chicago, Illinois, welcomed Abbott to the team in early August. She will be responsible for the overall operations of Cobra Systems. Everything from property management, administration and IT to accounting, purchasing, and human resources.

Abbott has an extensive background in the healthcare industry. She started…

Metal Trimming Market Forecast 2017 : Cobra, Starrett, Cosen, Prosaw, Birkett Cu …

Metal Trimming

A market study based on the " Metal Trimming Market " across the globe, recently added to the repository of Market Research, is titled ‘Global Metal Trimming Market 2017’. The research report analyses the historical as well as present performance of the worldwide Metal Trimming industry, and makes predictions on the future status of Metal Trimming market on the basis of this analysis.

Request For Sample Copy of Report :…