Press release

Worldwide Analysis on 3D Printing Metal Market Strategies and Forecasts, 2017 to 2027

3D printing metal is also referred to as metal additive manufacturing. This is a manufacturing technology used for the production of complex structures and smaller designs. The introduction of 3D printing metal has helped manufacturers to design and develop complex structures with ease which would have not been possible without the use of conventional manufacturing techniques. 3D printing metal is a manufacturing technology in which manufacturing is done layer by layer and hence, the accuracy of the production is also increased to a higher level. This technique, most commonly, requires only metal powder which can be used to manufacture various parts and components as per the requirement of the producers. There are special machines which are capable of manufacturing such complex structures. However, they must be operated under human supervision. The use of powder metals for the manufacturing of products has enabled manufacturers to use several types of metals and their alloys. Thus, the permutation and combination of several metals has enabled industries to produce products which are more durable, economical and suitable to be used for various industrial and commercial applications.This additive manufacturing process collects the powder in the reservoir and then, according to the need, it deposits the metal powder on the manufacturing bed to form layers of the product. These layers usually have a thickness ranging from 20 µm to 100 µm. Once the layers are properly placed and distributed, they are either bound together (known as 3D printing) or melted using a high energy beam. In the second case, the bean source is ideally one high energy laser, but many systems use two or more lasers with varying power standards under the inert gas environment. The most commonly used processes are Laser Cusing, Selective Direct Metal Laser Sintering (DMLS) and Laser Melting (SLM). The lone exemption to this process is the Electron Beam melting (EBM) process which operates in full vacuum condition with the electron beam. The melting process is repeated layer by layer, slice by slice, until the last layer is melted and the full products are complete. Then it is removed from the powder bed and post processing is done according to the product requirements.

Request For Report Sample@ http://www.futuremarketinsights.com/reports/sample/rep-gb-2858

3D Printing Metal Market Dynamics:

When combined with powerful and modern tools that optimize analysis and simulation process to generate an optimal design solution, such technologized tools are able to design tools which produce perfect, lightweight designs that are functionally accurate and optimized for production via. 3D printing or additive manufacturing. The resulting parts do not only take a reduced amount of time to design, but are also lighter and significantly stronger than part designs that are manufactured using conventional manufacturing methods.

Owing to these enhanced properties, 3D printing metal has abundant applications in the automotive, aerospace, construction, defense and medical industries. 3D Printing Metal market is anticipated to grow in all the industrial and manufacturing sectors owing to its growing applications in lightweight engineering products. The 3D Printing Metal market is estimated to grow since the regulatory authorities are pressing the manufacturers to use products which are more ecofriendly and use minimum amount of natural resources during the production process. 3D Printing Metal Market has a lot of scope in research and development division since the researchers and scientists are coming up with new metal and softwares which are more efficient and economical. Space constraint is becoming an important factor for the manufacturers now, they are opting for more light and spacious products, which in turn, is expected to fuel the growth of the 3D Printing Metals market in the consumer goods sector. The market for the 3D Printing Metal is anticipated to grow at a healthy CAGR in the coming future. Furthermore, the growing applications of the products manufactured by 3D printing in commercial and industrial sectors is expected to propel the growth of the overall 3D Printing Metal market in the near future.

3D Printing Metal Market segmentation:

3D Printing Metal can be segmented on the basis of Raw Material, Manufacturing Process and End Use.

By Raw Material, the 3D Printing Metal Market can be segmented into:

Powder

Filament

On the basis of Manufacturing Process, the3D Printing Metal market can be segmented into:

Direct Metal Laser Sintering (DMLS)

Laser Melting (SLM)

Others

On the basis of End Use,the 3D Printing Metal market can be segmented into:

Aerospace & Defense

Defense

Engineering and industrial

Power

Medical & Dental

Others

3D Printing Metal MarketRegional Outlook:

3D Printing Metal can be divided into seven different geographical regions/divisions -- North America, Latin America, Western and Eastern Europe, Asia-Pacific Excluding Japan (APEJ), Japan, Middle East and Africa. The North America and European countries have presence of all industrial and commercial sectors alongside the existence of globally prominent players, which is a boon for the 3D Printing Metal market in these regions. The rapid industrialization in the Asia pacific region, especially in China and India, is estimated to fuel the growth of the 3D Printing Metal market. Industries and manufacturers are striving to reduce scrap rates in their operating plants and with the use of 3D printing metal technology, they are also efficiently doing it. Thus, the market is anticipated to grow in the near future. The use of 3D printing metal products in the consumer goods is becoming easier and economical owing to the new inventions and advances being made in this technology. Therefore, it is expected that the 3D Printing Metal market will see rapid growth in all the developed and developing countries in future.

Request For TOC@ http://www.futuremarketinsights.com/toc/rep-gb-2858

3D Printing Metal Market: Market Participants

Some of the market participants in the 3D Printing Metal market are:

3D Systems Corporation

Arcam AB

EOS GmbH Electro Optical Systems

Optomec Inc.

Voxeljet AG

GKN Plc

Sandvik AB

Renishaw Plc

Carpenter Technology Corporation

Renishaw Plc

LPW Technology

Future Market Insights (FMI) is a leading market intelligence and consulting firm. We deliver syndicated research reports, custom research reports and consulting services, which are personalized in nature. FMI delivers a complete packaged solution, which combines current market intelligence, statistical anecdotes, technology inputs, valuable growth insights, an aerial view of the competitive framework, and future market trends.

616 Corporate Way, Suite 2-9018,

Valley Cottage, NY 10989,

United States

T: +1-347-918-3531

F: +1-845-579-5705

Email: sales@futuremarketinsights.com

Website: www.futuremarketinsights.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Worldwide Analysis on 3D Printing Metal Market Strategies and Forecasts, 2017 to 2027 here

News-ID: 455719 • Views: …

More Releases from Future Market Insights

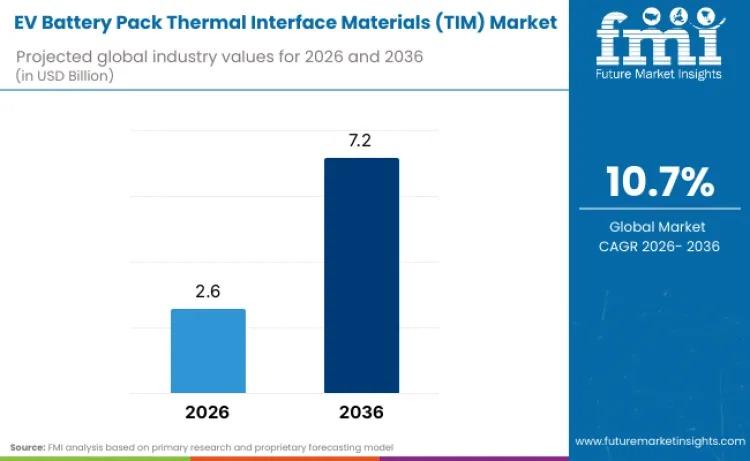

Global EV Battery Thermal Interface Materials Market to Reach USD 7.2 Billion by …

The global EV battery pack thermal interface materials (TIM) market is projected to grow from USD 2.6 billion in 2026 to USD 7.2 billion by 2036, advancing at a robust CAGR of 10.7%, according to recent analysis by Future Market Insights. This expansion reflects the accelerating electrification of transportation, rising energy density in battery systems, and increasingly stringent safety requirements that position thermal management as a critical determinant of vehicle…

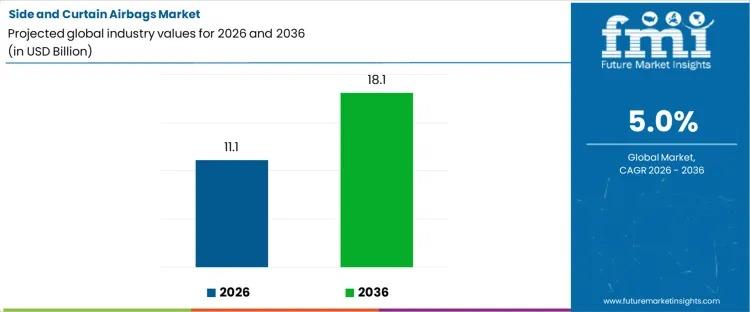

Global Side and Curtain Airbags Market to Reach USD 18.2 Billion by 2036 as Safe …

The global side and curtain airbags market is poised for sustained expansion as automotive manufacturers prioritize occupant protection and compliance with stringent crash safety regulations. According to the latest analysis by Future Market Insights, the market is projected to grow from USD 11.1 billion in 2026 to USD 18.2 billion by 2036, advancing at a CAGR of 5.0% during the forecast period.

This growth reflects the automotive industry's increasing emphasis on…

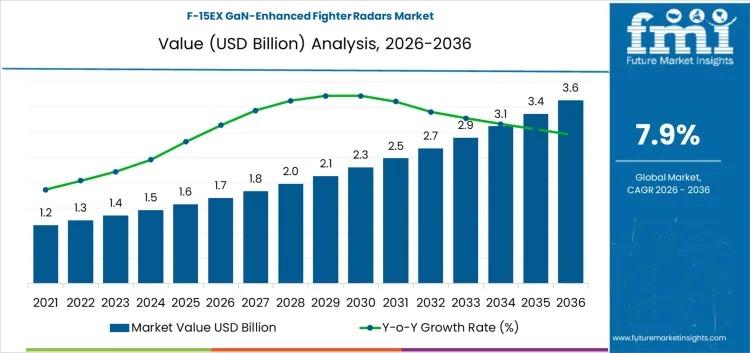

F-15EX GaN-Enhanced Fighter Radars Market to Reach USD 3.6 Billion by 2036 as De …

The global F-15EX GaN-enhanced fighter radars market is projected to grow from USD 1.7 billion in 2026 to USD 3.6 billion by 2036, registering a compound annual growth rate (CAGR) of 7.9% during the forecast period. This growth trajectory reflects the increasing integration of Gallium Nitride (GaN) semiconductor technology into advanced airborne radar systems, enabling superior detection, tracking, and electronic warfare resistance for modern fighter aircraft such as the F-15EX.

The…

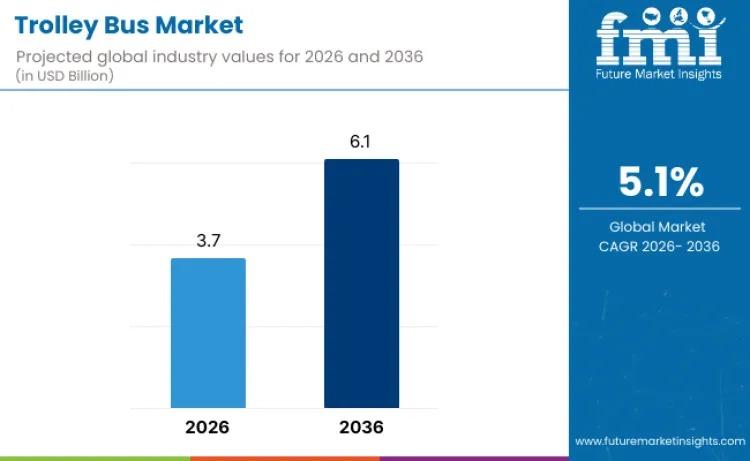

Global Trolley Bus Industry to Reach USD 6.1 Billion by 2036 as Urban Electrific …

The global trolley bus industry is entering a phase of sustained expansion, with market valuation projected to grow from USD 3.7 billion in 2026 to USD 6.1 billion by 2036, reflecting a steady compound annual growth rate (CAGR) of 5.1%. This upward trajectory is being driven by accelerating urban electrification programs, stringent zero-emission mandates, and mounting investment in sustainable public transportation infrastructure across major metropolitan regions worldwide.

As cities confront escalating…

More Releases for Metal

Metal Roofing Companies Revolutionizing the Industry: Classic Metal Roofs Leads …

Classic Metal Roofs has established itself as a leading provider of durable and energy-efficient roofing systems in Southern New England. With over 20 years of experience, the company is known for high-quality installations, customer satisfaction, and sustainable metal roofing solutions.

As homeowners increasingly seek durable and energy-efficient solutions, metal roofing companies continue to provide top-tier roofing systems. Among the industry leaders, Classic Metal Roofs [http://business.bigspringherald.com/bigspringherald/markets/article/abnewswire-2025-2-15-classic-metal-roofs-expert-aluminum-shingle-metal-roof-installation-and-services/] stands out for its commitment to…

Rare Metal Raw Materials - Boron(B) Metal

Boron Powder [https://www.urbanmines.com/boron-powder-product/]

Short Description:

Boron [,%20a%20chemical%20element%20with%20the%20symbol%20B%20and%20atomic%20number%205,%20is%20a%20black/brown%20hard%20solid%20amorphous%20powder.%20It%20], a chemical element with the symbol B and atomic number 5, is a black/brown hard solid amorphous powder. It is highly reactiveand soluble in concentrated nitric and sulfuric acids but insoluble in water, alcohol and ether. It has a high neutro absorption capacity. UrbanMines specializes in producing high purity Boron Powder with the smallest possible average grain sizes. Our standard powderparticle sizes average in the…

Metal Polishing Services Market Trends and Leading Players 2023-2030 | Metal Pol …

With a CAGR of 6.1%, the Metal Polishing Services Market is expected to grow from USD 1.5 billion in 2023 to USD 2.3 billion by 2030, offering a gleaming finish to metal surfaces for aesthetic and functional purposes.

Market Overview:

The Metal Polishing Services market is poised for rapid growth, driven by several pivotal drivers. There is a continuous demand for metal finishing and polishing services that improve the appearance and…

Metal-to-metal Seal Market 2021 | Detailed Report

Metal-to-metal Seal Market Forecasts report provided to identify significant trends, drivers, influence factors in global and regions, agreements, new product launches and acquisitions, Analysis, market drivers, opportunities and challenges, risks in the market, cost and forecasts to 2027.

Get Free Sample PDF (including full TOC, Tables and Figures) of Metal-to-metal Seal Market @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5089735

The report provides a comprehensive analysis of company profiles listed below:

- Parker

- CPI

- HTMS

- American Seal &…

Metal Polishing Services Market Research Report 2020 Analysis: Enhanced Growth a …

Metal Polishing Services Market

Global Metal Polishing Services Market is providing the summarized study of several factors encouraging the growth of the market such as manufacturers, market size, type, regions and numerous applications. By using the report consumer can recognize the several dynamics that impact and govern the market. For any product, there are several companies playing their role in the market, some new, some established and some are planning to…

Worldwide Recycled Metal Market By Metal 2024 | Nucor, Steel Dynamics, Schnitzer …

The 2018-2024 report on global Recycled Metal market explores the essential factors of Recycled Metal industry covering current scenario, market demand information, coverage of active companies and segmentation forecasts.

North America recycled metal market was estimated close to USD 8.5 billion in 2017. This is mainly attributed to strong presence of transportation, electrical & electronics and defense industry which majorly constitute to the overall product demand. Moreover, strict laws formulated…