Press release

Global 3D Weaving Market Size, Share & Growth Forecast (2026-2036)

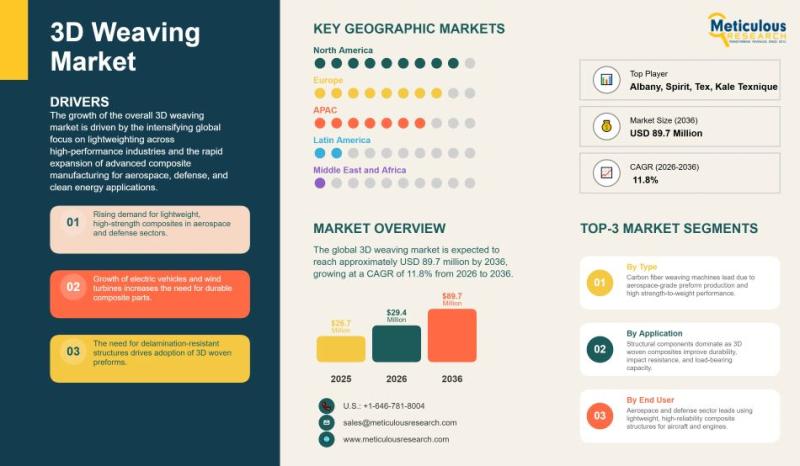

Global 3D Weaving Market set to reach USD 89.7M by 2036, driven by aerospace, EV lightweighting, and AI-enabled composites.

Download Sample Report Here: https://www.meticulousresearch.com/download-sample-report/cp_id=6478

Understanding 3D Weaving Technology

3D weaving is an advanced textile manufacturing technique that involves interlacing fibers simultaneously in the length, width, and thickness directions, resulting in fully integrated, multi-layer woven structures. Unlike conventional two-dimensional fabrics, which are prone to delamination and structural weakness, 3D woven preforms incorporate through-thickness reinforcement directly into the fabric architecture. This produces materials with enhanced damage tolerance, superior impact resistance, and excellent load-bearing capability under dynamic stress conditions. The technology allows manufacturers to create near-net-shape preforms that maintain structural integrity while reducing waste and improving performance. These advantages have made 3D weaving essential for producing components used in critical applications such as aerospace structural assemblies, defense platforms, electric vehicles, and large-format wind turbine blades.

Advanced Weaving Machinery

The market's growth is supported by a range of highly specialized weaving machines, including rapier and Jacquard-controlled systems capable of processing high-performance fibers such as carbon, aramid, and glass. These machines ensure precise fiber placement and consistency, forming the backbone of an advanced manufacturing value chain that extends from preform production to final component integration. Over time, these systems have evolved to include fully automated, digitally intelligent platforms that incorporate process monitoring, AI-driven weave pattern optimization, and predictive maintenance capabilities. These technological advancements enable manufacturers to reduce material waste, minimize development lead times, and maintain reproducible quality at industrial scale, further fueling the adoption of 3D weaving in high-value applications.

Market Drivers: Lightweighting and High-Performance Composites

The 3D weaving market is particularly driven by the demand for lightweight, high-strength composites in aerospace, defense, and automotive industries. Reducing structural weight while maintaining or improving mechanical strength, thermal stability, and impact resistance is a key priority across these sectors. Conventional laminated or tape-laid composites often fail to meet these stringent requirements, creating an opportunity for 3D woven structures, which provide multi-directional reinforcement and superior delamination resistance. Programs focused on next-generation aircraft engines, lightweight electric vehicles, and large offshore wind turbines rely on these advanced composite solutions to achieve performance targets while optimizing cost and manufacturing efficiency. In defense applications, there is also a growing emphasis on resilience and reliability, with 3D woven materials increasingly used for ballistic protection, hypersonic thermal shielding, and structural components that must withstand extreme operational conditions.

Browse in Depth: https://www.meticulousresearch.com/product/3d-weaving-market-6478

Sustainability and Circular Manufacturing

Beyond structural performance, 3D weaving is evolving to support sustainable manufacturing practices. There is a growing focus on utilizing recycled fibers, natural reinforcements, and thermoplastic matrix-compatible materials that support recyclability at the end of a product's life. This aligns with the broader industry shift toward reducing carbon emissions, energy consumption, and environmental impact throughout the manufacturing process. Advanced weaving systems now facilitate the production of semi-finished products and preforms from a wide range of fiber types, enabling manufacturers to meet both technical and environmental performance requirements. These developments open opportunities for 3D woven composites not only in traditional industrial applications but also in construction, medical textiles, and consumer goods, expanding the addressable market significantly.

Machine Type Insights

The market is segmented by machine type, with carbon fiber weaving systems accounting for the largest share in 2026. This segment dominates due to the critical role of carbon fiber in aerospace-grade preforms, next-generation engine components, and defense platforms, where high strength-to-weight ratios and fatigue resistance are essential. These machines are capable of producing complex, heavy-tow carbon fiber fabrics with high precision, enabling reliable supply for both original equipment and aftermarket applications. The composite textile weaving segment, which processes a broader range of technical fibers, is expected to witness the fastest growth. This is driven by expanding applications in electric vehicle crash structures, thermally stable aerospace panels, and biomedical implants that require adaptable fiber architectures.

Application Insights

In terms of applications, structural components hold the largest share of the 3D weaving market. The widespread use of 3D woven preforms in load-bearing aerospace structures, engine assemblies, and defense platforms is largely responsible for this dominance. These preforms enhance structural performance by improving damage tolerance and multi-directional load distribution, which is critical in high-performance applications. Protective materials, including ballistic armor panels, helmets, and blast-resistant structures, are anticipated to register the fastest growth. Rising defense investments, the demand for lightweight protection systems, and the development of advanced fiber architectures capable of multi-threat performance are driving the expansion of 3D woven applications in this segment.

End-Use Industry Insights

The aerospace and defense sector is the leading end-use industry in the 3D weaving market, driven by its ability to leverage the technology's performance benefits to achieve weight savings, improved lifecycle costs, and superior safety outcomes. Large-scale aerospace programs, military aircraft platforms, hypersonic systems, and next-generation propulsion units are all creating sustained demand for high-precision 3D woven components. Meanwhile, the automotive segment is expected to experience rapid growth through 2036, fueled by the global shift toward electric vehicles and the need for lightweight structural components that enhance crash safety and energy efficiency. In this context, 3D woven composites offer a viable alternative to traditional metal and chopped-fiber composites for achieving performance and regulatory compliance goals.

Regional Insights

Regionally, North America holds the largest share of the 3D weaving market in 2026, due to the concentration of advanced composite manufacturers, a well-funded aerospace and defense industrial base, and significant investment in research and development. Strong institutional support and strategic domestic programs have further reinforced North America's position as a global leader in 3D weaving technology. Europe maintains a significant market presence as well, backed by a strong industrial ecosystem and precision engineering expertise in textile machinery. Countries with established aerospace and automotive sectors are supporting steady domestic demand while exporting technology globally. Asia-Pacific is projected to experience the fastest growth over the forecast period, driven by large-scale capacity expansion in countries such as China and India. The growth is supported by government initiatives, cost-competitive manufacturing environments, and the increasing adoption of 3D weaving solutions in aerospace, automotive, and renewable energy applications.

Technological Advancements and Market Evolution

The global 3D weaving market is defined by continuous innovation in both equipment and processes. The industry is moving toward fully automated, digitally intelligent systems capable of handling a broad range of fibers while minimizing downtime and material waste. Advanced AI-driven capabilities allow manufacturers to optimize weave patterns, monitor tension in real-time, and predict maintenance needs, significantly improving production efficiency. The integration of these technologies facilitates the production of near-net-shape components with high structural performance, meeting the demanding requirements of aerospace, defense, automotive, and energy sectors. At the same time, there is a growing emphasis on sustainability, with an increasing number of systems capable of processing recycled and bio-based fibers for applications that extend beyond traditional high-performance industries.

Buy the Complete Report with an Impressive Discount: https://www.meticulousresearch.com/view-pricing/1795

Future Outlook

The market continues to expand as global manufacturing faces pressure to reduce component weight, enhance energy efficiency, and extend service life. The adoption of 3D woven composites enables manufacturers to overcome the limitations of conventional tape-laying and lamination processes, producing fiber architectures that were previously unattainable. Growing investments in defense programs, commercial aircraft production, and renewable energy infrastructure are reinforcing demand for reliable, high-quality 3D weaving equipment capable of supporting both prototyping and large-scale production. Across regions, the combination of advanced machinery, innovative fiber architectures, and digital intelligence is driving substantial growth, ensuring that the global 3D weaving market remains a dynamic and rapidly expanding segment of the advanced manufacturing landscape.

Key Questions Answered

What is the projected market value of the 3D weaving industry by 2036?

What is the expected CAGR of the 3D weaving market during the forecast period (2026-2036)?

How does 3D weaving differ from conventional 2D composite manufacturing techniques?

How are automation and AI transforming 3D weaving systems?

What role does digital process monitoring play in improving production efficiency?

How is near-net-shape manufacturing influencing composite component development?

Which machine type segment holds the largest share in the 3D weaving market?

Why do carbon fiber weaving machines dominate the market?

Which application segment accounts for the largest share of the market?

Why are structural components a key growth area for 3D woven composites?

Related Reports:

3D Food Printing Market: https://www.meticulousresearch.com/product/3d-food-printing-market-4995

Robotic Welding Market: https://www.meticulousresearch.com/product/robotic-welding-market-5303

About Us:

We are a trusted research partner for leading businesses worldwide, empowering Fortune 500 organizations and emerging enterprises with actionable market intelligence tailored to drive revenue transformation and strategic growth. Our insights reveal forward-looking revenue opportunities, providing our clients with a competitive edge through a diverse suite of research solutions-syndicated reports, custom research, and direct analyst engagement.

Each year, we conduct over 300 syndicated studies and manage 60+ consulting engagements across eight key industry sectors and 20+ geographic markets. With a focus on solving the complex challenges facing global business leaders, our research enables informed decision-making that propels sustainable growth and operational excellence. We are dedicated to delivering high-impact solutions that transform business performance and fuel innovation in the competitive global marketplace.

Contact Us:

Meticulous Market Research Pvt. Ltd.

1267 Willis St, Ste 200 Redding,

California, 96001, U.S.

Email- sales@meticulousresearch.com

USA: +1-646-781-8004

Europe: +44-203-868-8738

APAC: +91 744-7780008

Visit Our Website: https://www.meticulousresearch.com/

For Latest Update Follow Us:

LinkedIn- https://www.linkedin.com/company/meticulous-research

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global 3D Weaving Market Size, Share & Growth Forecast (2026-2036) here

News-ID: 4398578 • Views: …

More Releases from Meticulous Research®

Global Food Inspection Device Market Size, Growth Analysis & Forecast (2026-2036 …

The global food inspection device market has emerged as a critical component of modern food production, reflecting the increasing importance of consumer safety, regulatory compliance, and operational efficiency in the food industry. Valued at USD 3.35 billion in 2025, the market is projected to grow substantially over the coming decade, reaching approximately USD 8.33 billion by 2036, up from USD 3.57 billion in 2026, at a compound annual growth rate…

Global Flexible Printed Circuit Boards (FPCB) Market Size, Share, Growth Trends, …

The global flexible printed circuit boards (FPCB) market has witnessed remarkable growth over the past few years, emerging as a key segment within the electronics industry due to its ability to meet the evolving demands of miniaturized, high-performance devices. Valued at USD 21.5 billion in 2025, the market is poised to expand to approximately USD 22.8 billion in 2026 and is expected to reach USD 50.0 billion by 2036, registering…

eCOA Solutions Industry Analysis, Trends, and Revenue Outlook 2026-2036 | Meticu …

eCOA Solutions Market Size and Growth Outlook

The global electronic clinical outcome assessment (eCOA) solutions market was valued at USD 1.74 billion in 2025 and is projected to reach approximately USD 7.46 billion by 2036. From USD 1.94 billion in 2026, the market is expected to grow at a strong CAGR of 14.4% through 2036. This rapid expansion reflects a major transformation taking place across the global clinical research industry. As…

Industrial Gases Market to Reach USD 193.72 Billion by 2036 at 4.7% CAGR

Industrial Gases Market Size and Growth Outlook

The global industrial gases market was valued at USD 111.47 billion in 2025 and is projected to reach approximately USD 193.72 billion by 2036. From USD 122.01 billion in 2026, the market is expected to grow at a compound annual growth rate of 4.7% through 2036. This steady expansion reflects the essential role industrial gases play across manufacturing, healthcare, energy, and electronics sectors. As…

More Releases for USD

Bone Cement Market Outlook USD 1,871.10M-USD 3,512.31M

How Is the Bone Cement Market Supporting the Rise of Modern Orthopedic Surgery?

The Bone Cement Market plays a critical role in modern orthopedic and spinal procedures, acting as a foundational material for joint replacement, fracture fixation, and vertebral stabilization. Bone cement is widely used to anchor implants, restore bone structure, and improve patient mobility-making it an essential component of musculoskeletal care.

In 2025, the global bone cement market was valued at…

Autologous Cell Therapy Market Outlook USD 9.31B-USD 54.83B

How Is the Autologous Cell Therapy Market Redefining the Future of Precision Medicine?

The Autologous Cell Therapy Market is rapidly emerging as one of the most transformative areas in modern healthcare, offering highly personalized treatment options for complex and chronic diseases. By using a patient's own cells to repair, replace, or regenerate damaged tissues, autologous cell therapy minimizes immune rejection risks while maximizing therapeutic effectiveness.

In 2025, the global autologous cell therapy…

PACS Market USD 5.59B in 2025, USD 9.73B by 2035

Picture Archiving and Communication System (PACS) Market Expands as Digital Imaging Transforms Global Healthcare

Introduction: PACS at the Core of Modern Medical Imaging

The healthcare industry is undergoing a rapid digital transformation, with medical imaging playing a critical role in diagnosis, treatment planning, and patient monitoring. At the heart of this transformation lies the Picture Archiving and Communication System (PACS)-a technology that enables the storage, retrieval, management, and sharing of medical images…

Global HEOR Market USD 1.70B-USD 6.03B

Health Economics and Outcomes Research (HEOR) Market Accelerates as Value-Based Healthcare Redefines Global Decision-Making

Introduction: The Growing Importance of HEOR in Modern Healthcare

The global healthcare industry is undergoing a profound transformation, shifting from volume-driven care models to value-based healthcare systems that prioritize patient outcomes, cost efficiency, and real-world effectiveness. At the center of this transformation lies Health Economics and Outcomes Research (HEOR)-a discipline that evaluates the economic value, clinical outcomes, and…

Foam Tape Market Outlook 2035: Industry Growth from USD USD 4.89 Billion (2025) …

The Foam Tape Market plays a vital role in modern industrial and manufacturing ecosystems. Foam tapes are pressure-sensitive adhesive products manufactured using materials such as polyurethane, polyethylene, PVC, and acrylic foam. These tapes are widely used for bonding, sealing, insulation, cushioning, vibration damping, and noise reduction across multiple industries. Their ability to replace traditional mechanical fasteners like screws, bolts, and rivets has positioned foam tapes as a preferred solution in…

Chlorella Market Reach USD 465.85 Million USD by 2030

Market Growth Fueled by Increased Adoption of Plant-Based Proteins and Health Supplements

Global Chlorella Market size was valued at USD 303.75 Mn. in 2023 and the total Chlorella revenue is expected to grow by 6.3 % from 2024 to 2030, reaching nearly USD 465.85 Mn. . The growth of the market is majorly due to increase in the consumer awareness about health, the inclination towards plant-based food such as chlorella and…