Press release

Vinyl Flooring Manufacturing Plant DPR - 2026: Investment Cost, Market Growth and Machinery

Vinyl flooring is a synthetic flooring material made from polyvinyl chloride (PVC), widely used in both residential and commercial spaces. Known for its durability, versatility, water resistance, and cost-effectiveness, vinyl flooring is available in various forms including sheets, tiles, and planks, and can convincingly mimic the appearance of premium materials such as hardwood, stone, and ceramic tile. It is extensively used in homes, offices, healthcare facilities, retail spaces, hotels, and public infrastructure projects due to its ease of installation, low maintenance requirements, and long-lasting performance.With increasing demand for affordable, durable, and easy-to-maintain flooring solutions across residential, commercial, and industrial sectors-combined with booming construction activity in emerging economies and ongoing renovation projects worldwide-vinyl flooring manufacturing represents one of the most attractive investment opportunities in the building materials industry.

IMARC Group's report, "Vinyl Flooring Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a plant. The vinyl flooring manufacturing plant setup report offers insights into the process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Market Overview and Growth Potential

The global vinyl flooring market has demonstrated exceptional growth and continues to offer outstanding expansion potential. According to IMARC Group, the global vinyl flooring market was valued at USD 60.99 Billion in 2025 and is projected to reach USD 140.66 Billion by 2034, exhibiting a compound annual growth rate (CAGR) of 9.73% during 2026-2034-positioning it as one of the fastest-growing segments in the global flooring industry.

The market is growing at a substantial rate driven by the rising demand for economical, durable, and easy-to-maintain flooring options. The construction sector-encompassing both residential and commercial buildings as well as renovation-remains the key driving factor. The residential construction sector, which expanded at 6.8% during FY2024-25, is projected to reach USD 350 Billion by 2030, according to industry reports. Additionally, the ability of vinyl flooring to replicate high-quality materials like wood and stone while remaining within budget has ensured its continued popularity among cost-conscious consumers and commercial buyers alike.

Grab a sample PDF of this report: https://www.imarcgroup.com/vinyl-flooring-manufacturing-plant-project-report/requestsample

Plant Capacity and Production Scale

The proposed vinyl flooring manufacturing facility is designed with an annual production capacity ranging between 1-5 million sq.m., enabling economies of scale while maintaining operational flexibility. This scalable design allows manufacturers to serve diverse market segments-including residential interiors, commercial spaces, industrial facilities, and hospitality and leisure projects-while adjusting production volumes in response to evolving market demand and regional construction cycles.

Financial Viability and Profitability Analysis

The vinyl flooring manufacturing project demonstrates healthy profitability potential under normal operating conditions. The plant's financial performance is supported by stable demand across construction and renovation markets and diversified value-added applications:

• Gross Profit Margins: 30-40%, supported by consistent demand from residential and commercial construction sectors and versatile product positioning

• Net Profit Margins: 12-20%, reflecting efficient raw material management, scalable production operations, and diversified end-use market penetration

These margins position vinyl flooring manufacturing as an attractive investment proposition, particularly for manufacturers leveraging advanced production technologies such as digital printing and improved wear layers that enable premium product lines and enhanced pricing power.

Operating Cost Structure

The operating cost structure of a vinyl flooring manufacturing plant is primarily driven by raw material consumption, particularly PVC resin. Key cost components include:

• Raw Materials (PVC resin, plasticizers, fillers, and print film): 60-70% of total OpEx

• Utilities (electricity, water, steam): 10-15% of total OpEx

The primary raw materials include PVC resin as the base polymer, plasticizers for flexibility, mineral fillers for dimensional stability, and print films for aesthetic design layers. Effective cost management strategies include securing long-term contracts with reliable suppliers to stabilize pricing, conducting sustainability and supply chain risk assessments, and minimizing transportation costs through strategic supplier proximity. The relatively moderate utility cost component reflects the energy requirements for extrusion, calendaring, curing, and lamination processes.

Capital Investment Requirements

Establishing a vinyl flooring manufacturing plant involves significant capital expenditure components. Machinery costs account for the largest portion of total CapEx, followed by land and site development, civil works, and other capital cost. The key equipment requirements include:

• High-speed mixers for PVC compound preparation and blending

• Calenders or extrusion lines for sheet and plank formation

• Precision embossing rollers for surface texture and pattern creation

• Curing ovens for thermal stabilization and product hardening

• Multi-layer press laminators for composite layer bonding

• Precision cutting and trimming systems for dimensional accuracy

• Automated packing stations for efficient finished goods handling

Additional capital investments cover land acquisition, site preparation, infrastructure development, quality control laboratories, environmental monitoring systems, and utility infrastructure including electricity, water supply, and steam generation. The integration of digital printing technology and advanced wear-layer systems into the production line further enhances product quality, design versatility, and market competitiveness.

Speak to an Analyst: https://www.imarcgroup.com/request?type=report&id=7336&flag=C

Major Applications and Market Segments

Vinyl flooring serves diverse end-use sectors with broad market appeal across multiple construction and renovation segments:

• Residential Interiors: Durable, easy-to-maintain flooring for living spaces, kitchens, bedrooms, and bathrooms

• Commercial Spaces: High-traffic flooring for offices, retail stores, hospitals, schools, and educational institutions

• Industrial Facilities: Wear-resistant, chemical-tolerant flooring for factories, warehouses, and processing plants

• Hospitality and Leisure: Aesthetic, slip-resistant flooring for hotels, resorts, restaurants, and recreational areas

Why Invest in Vinyl Flooring Manufacturing?

Vinyl flooring manufacturing presents multiple strategic advantages for investors and building materials entrepreneurs:

• High Demand for Durable and Affordable Flooring: Vinyl flooring is increasingly preferred for its ability to withstand heavy foot traffic, moisture, and wear and tear, making it a go-to choose in both residential and commercial settings across all price segments.

• Versatile Product Offering: Vinyl flooring offers a wide range of designs, patterns, and finishes that mimic premium materials such as hardwood, stone, and tile, making it a versatile choice for customers with varying tastes and budgets-from economy to luxury segments.

• Technological Advancements in Production: Continuous advancements in manufacturing processes such as digital printing and improved wear layers are enhancing product quality, expanding design possibilities, and strengthening market potential.

• Growing Construction and Renovation Activities: The construction boom, particularly in emerging economies, along with ongoing renovation and refurbishment projects in developed countries, is driving demand for vinyl flooring as a cost-effective, long-lasting, and aesthetically appealing solution.

Industry Leadership

The global vinyl flooring industry features several leading manufacturers with extensive production capacities and diverse application portfolios.

• Shaw Industries

• Tarkett

• Mohawk Industries

• Gerflor

• Armstrong Flooring

These companies serve end-use sectors spanning residential, commercial, healthcare, retail, and hospitality markets, with product portfolios covering sheets, tiles, planks, and hybrid resilient flooring solutions.

Buy Now: https://www.imarcgroup.com/checkout?id=7336&method=2175

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Vinyl Flooring Manufacturing Plant DPR - 2026: Investment Cost, Market Growth and Machinery here

News-ID: 4393762 • Views: …

More Releases from IMARC Group

Lithium Iron Phosphate (LiFePO4) Battery Manufacturing Plant Cost: Feasibility S …

The global lithium iron phosphate (LiFePO4) battery manufacturing industry represents a critical technological frontier supporting the worldwide transition toward sustainable energy storage and electric mobility solutions. Lithium iron phosphate (LiFePO4) batteries are a type of lithium-ion battery that uses lithium iron phosphate as the cathode material. They are known for their high energy density, thermal stability, and safety characteristics. Unlike traditional lithium-ion batteries, LiFePO4 batteries offer excellent thermal and chemical…

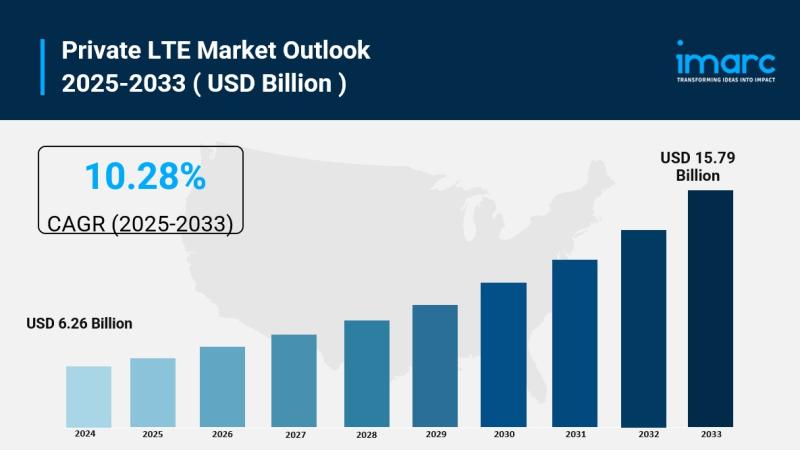

Private LTE Market is Expected to Reach USD 15.79 Billion by 2033 | At CAGR 10.2 …

Private LTE Market Overview:

The global Private LTE Market was valued at USD 6.26 Billion in 2024 and is forecast to reach USD 15.79 Billion by 2033, growing at a CAGR of 10.28% during 2025-2033. This growth is driven by rising demand for secure and reliable wireless connectivity in industrial sectors, increasing adoption of IoT and Industry 4.0 technologies, availability of shared spectrum solutions, and expanding requirements for mission-critical communications across…

Biopesticide Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Pr …

Biopesticides represent one of the fastest-growing segments in the global agricultural inputs market. As crop protection solutions sourced from natural origins - including beneficial microorganisms, plant extracts, insects, and select minerals - biopesticides manage pests, weeds, and plant diseases through biological processes rather than synthetic chemicals. Their key types include microbial biopesticides, botanical formulations, biochemical agents, and pheromone-based products.

With rising awareness about sustainable agriculture, tightening restrictions on chemical pesticides, and…

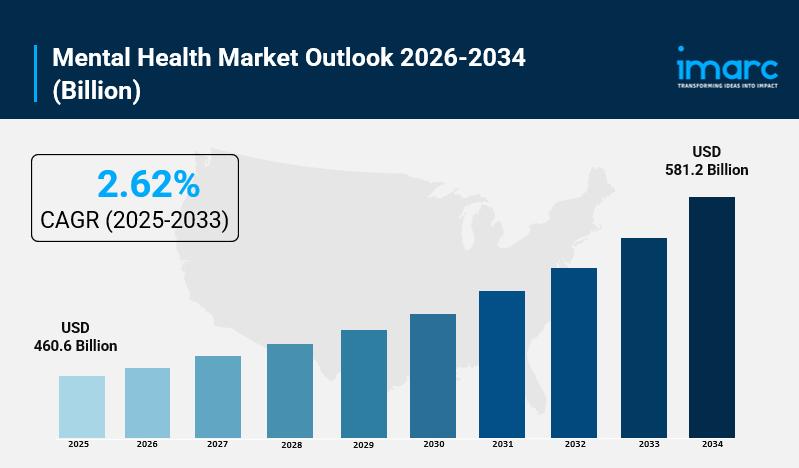

Mental Health Market Size, Share, Industry Trends, Growth Factors and Forecast 2 …

IMARC Group, a leading market research company, has recently released a report titled "Mental Health Market Size, Share, Trends, and Forecast by Disorder, Service, Age Group, and Region 2026-2034." The study provides a detailed analysis of the industry, including the global mental health market size, trends, share and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Mental Health Market Highlights:

• Mental Health…

More Releases for Vinyl

Market Overview - Transparent Vinyl

QY Research has recently published a comprehensive market study on Transparent Vinyl, a widely used flexible plastic material based primarily on plasticized polyvinyl chloride (PVC). Transparent vinyl combines optical clarity, flexibility, durability, and cost efficiency, making it a core material for packaging, medical products, protective films, signage, stationery, and consumer goods.

The market is transitioning from conventional high-plasticizer formulations toward low-toxicity, phthalate-free, and specialty transparent vinyl grades optimized for medical safety,…

Vinyl Cyclohexane Market

"Vinyl Cyclohexane Market" in terms of revenue was estimated to be worth $64.7 Mn in 2023 and is poised to reach $109.8 Mn by 2031, growing at a CAGR of 7.05% from 2023 to 2031 according to a new report by InsightAce Analytic.

Get Free Access to Demo Report, Excel Pivot and ToC: https://www.insightaceanalytic.com/request-sample/1539

Latest Drivers Restraint and Opportunities Market Snapshot:

Key factors influencing the global Vinyl Cyclohexane market are:

• Increasing Demand in…

Vinyl Flooring and Vinyl Tiles Market 2025: Big Things are Happening

Global Vinyl Flooring and Vinyl Tiles Sales Market Detailed Trend Analysis & Forecast is the latest research study released by HTF MI evaluating the market risk side analysis, highlighting opportunities, and leveraging strategic and tactical decision-making support. The report provides information on market trends and development, growth drivers, technologies, and the changing investment structure of the Global Vinyl Flooring and Vinyl Tiles Market. Some of the key players profiled in…

Vinyl Flooring and Vinyl Tiles Market to See Booming Business Sentiments

The latest research study released by AMA on the Vinyl Flooring and Vinyl Tiles Market offers over 181+ pages of analysis on business strategies employed by key and emerging industry players. It provides insights into current market developments, landscape, technologies, drivers, opportunities, market outlook, and status. The market study is segmented by key regions driving market growth. The Vinyl Flooring and Vinyl Tiles study combines qualitative and quantitative market data,…

Vinyl Flooring Market By Product (Luxury Vinyl Tile And Vinyl Sheets & Vinyl Com …

Vinyl flooring, also known as resilient flooring, is a finished flooring material primarily used in construction application related to commercial and industrial applications. It is made from a combination of natural and synthetic polymer materials such as polyvinyl chloride and plasticizers. Vinyl flooring is available in the form of sheet, tile, and plank, specially designed for residential and commercial use. Low cost, durability, …

Global Vinyl Chloride Monomer (VCM) Market 2018 - LG Chem, Tokuyama, Qatar Vinyl

Apex Market Research, recently published a detailed market research study focused on the "Vinyl Chloride Monomer (VCM) Market" across the global, regional and country level. The report provides 360° analysis of "Vinyl Chloride Monomer (VCM) Market" from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global Vinyl Chloride Monomer (VCM) industry, and estimates the…