Press release

Powder Metallurgy Market Sees Rapid Expansion Amid Automotive and EV Adoption

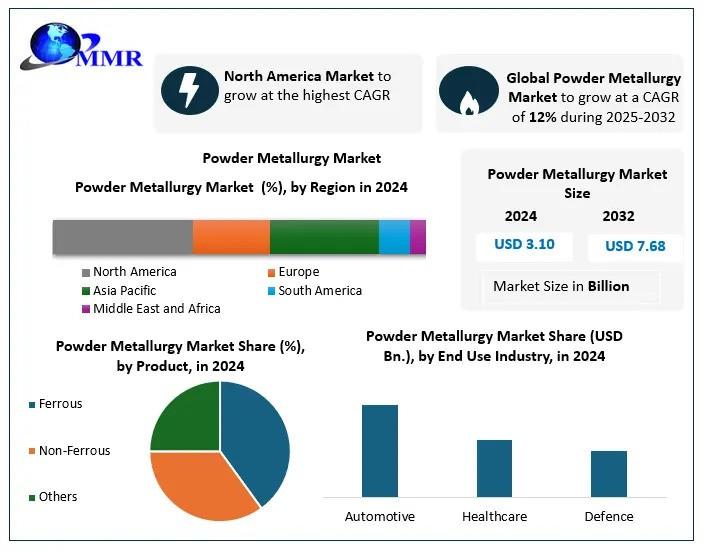

Powder Metallurgy Market size was valued at USD 3.10 Bn. in 2024, and the total Powder Metallurgy Market revenue is expected to grow at a CAGR of 12% from 2025 to 2032, reaching nearly USD 7.68 Bn.Powder Metallurgy Market Overview:

The powder metallurgy market is increasingly positioned as a critical manufacturing route for producing high-precision, near-net-shape components across automotive, industrial machinery, electrical & electronics, aerospace, and medical device applications. Powder metallurgy enables manufacturers to convert metal powders-such as iron, steel, aluminum, copper, titanium, and specialty alloys into complex geometries with minimal material wastage and superior dimensional control. This manufacturing approach supports high-volume production while ensuring consistency, repeatability, and cost efficiency, making it attractive for OEMs focused on lean manufacturing and material optimization. The powder metallurgy process ecosystem includes powder production, blending, compaction, sintering, secondary machining, and surface finishing, allowing flexibility across both structural and functional component manufacturing. Increasing adoption of advanced powder metallurgy techniques such as metal injection molding (MIM), hot isostatic pressing (HIP), and additive manufacturing-based powder sintering is expanding application potential beyond traditional automotive parts. From an industry standpoint, powder metallurgy aligns strongly with lightweighting strategies, energy efficiency goals, and sustainable manufacturing objectives, particularly as manufacturers seek alternatives to casting and forging processes that involve higher rates and energy consumption.

Download Free Sample & Check the Latest Market Analysis: https://www.maximizemarketresearch.com/request-sample/55292/

Powder Metallurgy Market Dynamics:

The powder metallurgy market dynamics are shaped by a combination of industrial demand patterns, evolving material science capabilities, and shifting manufacturing economics. On the demand side, OEMs are increasingly prioritizing component miniaturization, tight tolerance control, and design flexibility-areas where powder metallurgy processes offer a structural advantage. Supply-side dynamics are influenced by fluctuations in metal powder pricing, availability of high-purity alloy powders, and technological barriers associated with powder handling and sintering consistency. Additionally, powder metallurgy production requires capital-intensive equipment such as compaction presses, controlled-atmosphere sintering furnaces, and precision tooling, which can impact entry barriers for small manufacturers. Regulatory dynamics related to occupational safety, metal powder dust management, and emissions from sintering operations are also influencing operational strategies, especially in Europe and North America. Furthermore, end-user industries such as automotive and industrial equipment are undergoing platform consolidation, which affects long-term supplier contracts and demand visibility. Collectively, these dynamics create a market environment where scale, process automation, material innovation, and supplier reliability are decisive factors shaping competitive positioning.

Powder Metallurgy Market Key Drivers of Growth:

One of the primary drivers of growth in the powder metallurgy market is the rising demand for lightweight, high-strength components in the automotive and mobility sector, particularly for internal engine systems, transmission components, and electric vehicle platforms. Powder metallurgy enables optimized material distribution, which helps reduce component weight while maintaining mechanical integrity. Another significant growth driver is the increasing need for cost-effective mass production of complex geometries without extensive machining, supporting operational efficiency for OEMs. Industrial automation, robotics, and power tools are also driving demand for sintered components that require consistent performance under mechanical stress. Advancements in metal powder formulation-such as alloy customization, particle size optimization, and enhanced flowability-are further expanding use cases. Additionally, powder metallurgy supports sustainability goals by minimizing generation and enabling high material utilization rates, aligning with ESG-driven manufacturing strategies. Growth is also reinforced by increasing adoption of metal injection molding in medical devices, electronics connectors, and precision instruments where dimensional accuracy is critical.

Get a Customized Market View in One Click: https://www.maximizemarketresearch.com/market-report/global-powder-metallurgy-market/55292/

Powder Metallurgy Market Segment Analysis:

by Product

Ferrous

Non-ferrous

Others

by End Use

Industry Defence

Healthcare

Automotive

by Application

Electrical & Electronics

Industrial Machinery

Medical Devices

Aerospace

Powder Metallurgy Market Regional Analysis:

From a regional perspective, Asia-Pacific dominates the powder metallurgy market due to strong automotive manufacturing bases, expanding industrial machinery production, and growing investments in electric vehicle supply chains. Countries such as China, Japan, South Korea, and India benefit from vertically integrated powder production ecosystems and cost-competitive labor structures. Europe remains a technologically advanced region, driven by stringent emission regulations, lightweighting mandates, and strong demand from automotive OEMs and industrial automation companies, particularly in Germany, Italy, and France. North America shows stable growth supported by aerospace, defense, and medical device manufacturing, with increasing emphasis on high-performance alloys and additive manufacturing powders. Latin America and the Middle East & Africa represent emerging markets, where powder metallurgy adoption is gradually increasing due to infrastructure development and localized manufacturing initiatives. Regional competitiveness is strongly influenced by access to raw materials, energy costs, environmental compliance requirements, and proximity to OEM manufacturing hubs, making regional supply chain optimization a strategic priority for global powder metallurgy players.

Opportunities in the Powder Metallurgy Market:

The powder metallurgy market presents substantial opportunities driven by technological convergence and evolving end-user requirements. One major opportunity lies in the integration of powder metallurgy with additive manufacturing, enabling hybrid production models that combine design freedom with high-volume sintering efficiency. Growing electric vehicle penetration opens new avenues for powder metallurgy in soft magnetic components, thermal management parts, and lightweight structural assemblies. The medical and dental sectors offer high-margin opportunities, particularly for titanium-based powders used in implants and surgical instruments. Additionally, industrial sustainability initiatives are creating demand for manufacturing processes that reduce energy consumption and material waste, positioning powder metallurgy as a preferred alternative to traditional subtractive methods. Opportunities also exist in localized powder production to mitigate supply chain risks and reduce dependency on imported metal powders. For suppliers, offering customized powder blends, application-specific sintering solutions, and value-added secondary operations can unlock long-term OEM partnerships and recurring revenue streams.

Download Free Sample & Check the Latest Market Analysis: https://www.maximizemarketresearch.com/request-sample/55292/

Powder Metallurgy Market Future Outlook:

The future outlook for the powder metallurgy market remains structurally positive as manufacturing industries continue to prioritize efficiency, precision, and sustainability. Technological advancements in powder atomization, sintering atmospheres, and process automation are expected to improve yield consistency and reduce defect rates. The market is likely to see greater adoption of digital quality monitoring, AI-driven process optimization, and closed-loop production systems. Demand growth is anticipated from electric mobility, renewable energy equipment, and advanced industrial machinery, where material performance and weight optimization are critical. At the same time, competitive intensity will increase as global players expand capacity and regional manufacturers invest in advanced sintering technologies. The future market landscape will favor companies that can combine material science expertise with scalable production capabilities and strong OEM relationships. Strategic collaborations between powder producers, equipment manufacturers, and end-use industries will play a pivotal role in shaping long-term market evolution.

Some of the most prominent and loved players in the Powder Metallurgy Market from

all over the world are:

North America

1. Carpenter Technology Corporation - United States

2. Rio Tinto Metal Powders - Canada

3. Allegheny Technologies Incorporated (ATI) - United States

4. Molyworks Materials Corporation - United States

Europe

1. Sandvik AB - Sweden

2. Hoganas AB - Sweden

3. POLEMA JSC - Russia

4. Carl Schlenk AG - Germany

5. GKN Plc - United Kingdom

6. Miba AG - Austria

APAC

1. Advanced Technology & Materials Co., Ltd. (AT&M) - China

2. JSC Polema - Russia

3. Hitachi Chemical Co., Ltd - Japan

4. Sumitomo Electric Industries, Ltd - Japan

5. POLEMA JSC - Russia

What are the major key trends in the Powder Metallurgy Market:

Several key trends are reshaping the powder metallurgy market, starting with the increasing shift toward high-performance and specialty alloy powders tailored for specific mechanical and thermal properties. Metal injection molding is gaining traction as a preferred manufacturing method for small, complex components across electronics, medical, and defense applications. Another notable trend is the growing use of powder metallurgy in electric powertrain components, particularly soft magnetic materials for motors and inductive systems. Sustainability-driven trends include the adoption of recycled metal powders and energy-efficient sintering processes. Digitalization is also emerging as a core trend, with manufacturers deploying smart furnaces, real-time process analytics, and predictive maintenance tools to enhance productivity. Additionally, regionalization of powder supply chains is becoming more prominent as manufacturers seek resilience against geopolitical and logistics disruptions. These trends collectively indicate a transition of powder metallurgy from a cost-focused manufacturing alternative to a strategically critical production technology.

Trending Reports:

Global Ovarian Cancer Drugs Market https://www.linkedin.com/pulse/ovarian-cancer-drugs-industry-2026-growth-drivers-market-rajput-89x1c

Power Plant Control System Market https://www.linkedin.com/pulse/power-plant-control-system-market-hit-1168-billion-2032-nnlic

Video Analytics Market https://www.linkedin.com/pulse/video-analytics-market-size-revenue-forecast-2024-2030-40bn-oph2c

MAXIMIZE MARKET RESEARCH PVT. LTD.

2nd Floor, Navale IT park Phase 3,

Pune Banglore Highway, Narhe

Pune, Maharashtra 411041, India.

+91 9607365656

sales@maximizemarketresearch.com

Maximize Market Research is one of the fastest-growing market research and business consulting firms serving clients globally. Our revenue impact and focused growth-driven research initiatives make us a proud partner of majority of the Fortune 500 companies. We have a diversified portfolio and serve a variety of industries such as IT & telecom, chemical, food & beverage, aerospace & defense, healthcare and others.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Powder Metallurgy Market Sees Rapid Expansion Amid Automotive and EV Adoption here

News-ID: 4380196 • Views: …

More Releases from MAXIMIZE MARKET RESEARCH PVT. LTD.

Ready-to-Drink Beverages Market Size to Reach USD 1,227.81 Billion by 2032

Ready-to-Drink Beverages Market is poised for substantial growth over the forecast period, driven by changing consumer lifestyles, rising disposable income, expanding urbanization, and increasing demand for convenient beverage solutions. According to recent industry analysis, the global Ready-to-Drink Beverages Market was valued at USD 766.69 Billion in 2024 and is projected to grow at a compound annual growth rate (CAGR) of 6.22% from 2025 to 2032, reaching nearly USD 1,227.81 Billion…

Second hand Product Market Set to Surpass USD 1451.34 Billion by 2032, Expanding …

Second hand Product Market was valued at USD 594.45 Billion in 2025 and is projected to grow at a robust CAGR of 13.6% from 2025 to 2032, reaching nearly USD 1451.34 Billion by 2032. The rapid expansion of resale ecosystems, increasing consumer preference for cost-effective purchasing, and rising sustainability awareness are significantly driving the growth of the Second hand Product Market globally.

Market Overview

The Second hand Product Market is undergoing a…

Tungsten Market to Reach USD 10.99 Billion by 2032, Driven by Expanding Aerospac …

The Global Tungsten Market is poised for significant expansion over the coming years, with the market size valued at USD 6.41 Billion in 2025 and projected to grow at a CAGR of 8% from 2025 to 2032, reaching nearly USD 10.99 Billion by 2032. Rising industrial demand, technological advancements in material science, and increasing applications in high-performance sectors are collectively driving this steady growth trajectory.

Tungsten, recognized for its exceptional hardness,…

System-on-Chip (SoC) Market to Reach USD 391.61 Billion by 2032, Driven by 5G, A …

The global System-on-Chip (SoC) Market is poised for significant growth over the forecast period, reflecting the rapid evolution of semiconductor technologies and increasing demand for high-performance, energy-efficient electronic devices. Valued at USD 228.06 Billion in 2025, the market is projected to grow at a CAGR of 8.03% from 2025 to 2032, reaching nearly USD 391.61 Billion by 2032.

♦ Request a Free Sample Copy or View Report Summary:https://www.maximizemarketresearch.com/request-sample/33954/

System-on-Chip (SoC) Market Overview

A…

More Releases for Powder

Polyolefin Powder Market, By Type (Polyethylene Powder, Polypropylene Powder),Tr …

Data Bridge Market Research analyses the polyolefin powder market will exhibit a CAGR of 6.00% for the forecast period of 2022-2029 and is expected to reach the USD 11.79 billion by 2029.

View Detailed Report: https://www.databridgemarketresearch.com/reports/global-polyolefin-powder-market

Polyolefin is a polymer made from the simple monomer olefin, and its powder is made up of crystalline polyolefin made from olefins. Paper coating, ink and paint formulation, and injection moulding are just a few of the applications…

Nano Ceramic Powder Market: Information by Type (Oxide Powder, Carbide Powder, B …

Nano Ceramic powder is nanoparticles which are inorganic solids made up of oxides, ceramics, carbonates, and carbides. The Nano-Ceramic powder has a growing market as they are very useful due to its very small size.

Nano Ceramic powder is strong and the strength of these powder is similar to steel. They exhibit strength at high temperatures. They are more resistant to chemical situations than other metals. There is some ceramic powder…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Global Egg Powder Market Status, Industry Player (Egg Powder, Egg Yolk Powder, E …

An up-to-date research report has been disclosed by Market Research Hub highlighting the title “Global Egg Powder Market Increasing Consumption of Whole Egg Powder to be Observed in the Coming Years” which provides an outlook for current market value as well as the expected growth of Egg Powder during 2018-2025. The report studies the casing heads market worldwide, especially in North America, China, Europe, Southeast Asia, Japan and India, with…