Press release

Gelatin Manufacturing Plant DPR 2026: Machinery Cost, Capex/Opex, ROI and Raw Materials

The global gelatin manufacturing industry is witnessing steady growth driven by the rapidly expanding food and beverage, pharmaceutical, and cosmetics sectors and increasing demand for natural protein-based ingredients with gelling, stabilizing, and thickening properties. At the heart of this expansion lies a critical functional ingredient-gelatin. As consumers worldwide seek natural, clean-label food additives and pharmaceutical manufacturers require high-quality excipients, establishing a gelatin manufacturing plant presents a strategically compelling business opportunity for entrepreneurs and specialty ingredients investors seeking to capitalize on this growing and essential market.IMARC Group's report, "Gelatin Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a plant. The gelatin manufacturing plant setup report offers insights into the process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Market Overview and Growth Potential

The global gelatin market demonstrates steady growth, valued at 477,092.61 Tons in 2025. According to IMARC Group's comprehensive market analysis, the market is projected to reach 535,904.86 Tons by 2034, exhibiting a CAGR of 1.3% from 2026-2034. This expansion is driven by rising consumption of confectioneries, dietary supplements, and health and beauty products, along with increasing demand in food and beverages, pharmaceuticals, and cosmetics sectors.

Gelatin is a natural protein resulting from hydrolysis of collagen from animal connective tissues found in bones, skin, and cartilage. The substance functions as a gelling agent, stabilizing agent, and thickening agent in various sectors including food (confectionery, desserts), pharmaceuticals (capsules, tablets), and cosmetics (creams, gels, lotions). Unique functional properties enable gelatin's use in various applications because it dissolves in hot water, creates films, and controls viscosity effectively.

The global gelatin market is primarily driven by increasing demand from food, pharmaceutical, and cosmetic sectors. Such expansions highlight robust growth potential driven by rising applications in food, pharmaceuticals, and nutraceuticals, and increasing consumer preference for high-quality specialized collagen products globally.

Request for a Sample Report: https://www.imarcgroup.com/gelatin-manufacturing-plant-project-report/requestsample

Plant Capacity and Production Scale

The proposed gelatin manufacturing facility is designed with an annual production capacity of 3,000 MT, enabling economies of scale while maintaining operational flexibility. This capacity allows manufacturers to cater to diverse market segments-from confectioneries, marshmallows, and desserts to capsules, tablets, and personal care products-ensuring steady demand and consistent revenue streams across multiple industry verticals.

Financial Viability and Profitability Analysis

The gelatin manufacturing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

• Gross Profit Margins: 30-45%

• Net Profit Margins: 15-25%

These margins are supported by stable demand across food and beverages, pharmaceuticals, and cosmetics sectors, value-added specialty ingredient positioning, and the critical nature of gelatin in numerous functional applications. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established specialty ingredients manufacturers looking to diversify their product portfolio in the protein-based functional ingredients segment.

Speak to Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=7652&flag=C

Operating Cost Structure

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a gelatin manufacturing plant is primarily driven by:

• Raw Materials: 50-60% of total OpEx

• Utilities: 20-25% of OpEx

Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Raw materials constitute the largest portion of operating costs, with animal bones/hides (ossein), acids, and alkalis being the primary input materials. Establishing long-term relationships with reliable raw material suppliers from meat processing and rendering facilities helps ensure consistent quality and supply, which is critical given that collagen-rich animal byproducts represent the most significant cost factor in gelatin manufacturing.

Buy Now: https://www.imarcgroup.com/checkout?id=7652&method=2175

Capital Investment Requirements

Setting up a gelatin manufacturing plant requires substantial capital investment across several critical categories:

Land and Site Development: Selection of an optimal location with strategic proximity to meat processing facilities, slaughterhouses, and rendering plants for reliable raw material supply. Proximity to food, pharmaceutical, and cosmetics manufacturing markets will help minimize distribution costs. The site must have robust infrastructure, including reliable transportation, utilities, and waste management systems. Compliance with local zoning laws, food safety regulations, and environmental regulations must also be ensured.

Machinery and Equipment: The largest portion of capital expenditure (CapEx) covers specialized production equipment essential for manufacturing. Key machinery includes:

• Extraction tanks and hydrolysis reactors for controlled acid or alkali treatment of raw collagen materials to break down protein structures

• Filtration systems and clarification equipment for removing impurities, fats, and undissolved proteins from crude gelatin solution

• Concentration units and evaporators for increasing gelatin concentration through moisture removal and achieving desired bloom strength

• Drying equipment including vacuum dryers or belt dryers for controlled moisture removal while maintaining gelatin quality and functionality

• Powder blenders and grinding mills for producing uniform gelatin powder with controlled particle size distribution for various applications

• Packaging machines for automated filling, sealing, and labeling of finished gelatin products in food-grade or pharmaceutical-grade containers

• Quality control laboratory equipment including bloom strength testers, viscosity analyzers, and microbiological testing instruments

• Effluent treatment systems for managing organic waste, process water, and byproducts to ensure environmental compliance and responsible disposal

Civil Works: Building construction, factory layout optimization, and infrastructure development designed to enhance workflow efficiency, ensure strict hygiene standards, and maintain the highest quality control throughout the production process. The layout should be optimized with separate areas for raw material storage and pre-treatment, extraction and hydrolysis zone, filtration section, concentration unit, drying area, powder processing section, quality control laboratory, finished goods warehouse, utility block, effluent treatment facility, and administrative block.

Other Capital Costs: Pre-operative expenses, machinery installation costs, food safety and pharmaceutical regulatory compliance certifications including HACCP and GMP, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Major Applications and Market Segments

Gelatin products find extensive applications across diverse market segments, demonstrating their versatility and critical importance:

Food and Beverages: Used in confectioneries, marshmallows, gummy candies, desserts, and dairy products where gelatin provides texture, mouthfeel, gelling properties, and stabilization for consistent product quality.

Pharmaceuticals: Utilized in hard and soft capsules, tablets, wound dressings, and medical implants where gelatin serves as an excipient, binder, and biocompatible material meeting stringent pharmaceutical standards.

Skin Care and Cosmetics: Employed in creams, gels, facial masks, and anti-aging formulations where gelatin's film-forming and moisturizing properties contribute to product performance and consumer satisfaction.

Why Invest in Gelatin Manufacturing?

Several compelling factors make gelatin manufacturing an attractive investment opportunity:

Essential Ingredient for Multiple Sectors: Gelatin functions as a vital component satisfying food, pharmaceutical, and cosmetic needs through its functional and textural properties, making it indispensable across industries.

Moderate Entry Barriers: Manufacturers who possess both technological expertise and quality control standards can achieve market advantage through their capacity to deliver products with dependable performance and product integrity.

Growing Market Demand: Consumer understanding of protein-rich foods, dietary supplements, and cosmetic products has increased, resulting in continuous product demand and expanding market opportunities globally.

Policy Support and Local Sourcing: Government programs supporting food processing and pharmaceutical manufacturing create opportunities for businesses to produce goods within their own communities with policy incentives.

Natural and Clean-Label Positioning: Growing consumer preference for natural, recognizable ingredients positions gelatin favorably against synthetic alternatives in food and cosmetic formulations.

Pharmaceutical Growth: Expanding pharmaceutical manufacturing, particularly in capsule production and drug delivery systems, drives sustained gelatin demand as an essential pharmaceutical excipient.

Value-Added Byproduct Utilization: Gelatin production utilizes animal byproducts from meat processing, creating value from materials that would otherwise require disposal, supporting circular economy principles.

Manufacturing Process Excellence

The gelatin manufacturing process involves several precision-controlled stages:

• Extraction: Animal bones, hides, and connective tissues are cleaned, degreased, and treated with acid or alkali solutions to break down collagen structures and remove non-collagen proteins

• Filtration: Crude gelatin solution undergoes multiple filtration stages using filter presses and membrane systems to remove particulates, fats, and impurities

• Hydrolysis: Filtered gelatin solution is subjected to controlled hydrolysis under specific temperature and pH conditions to achieve desired molecular weight and functional properties

• Concentration: Hydrolyzed gelatin solution is concentrated through evaporation to increase gelatin content and reduce moisture for subsequent processing stages

• Drying: Concentrated gelatin is dried using vacuum or belt dryers under controlled temperature to achieve target moisture content while preserving gel strength and functionality

• Powder Processing: Dried gelatin is ground, blended, and sieved to produce uniform powder with specified particle size distribution meeting customer requirements

• Quality Control and Packaging: Finished gelatin undergoes comprehensive testing for bloom strength, viscosity, pH, moisture, and microbiological safety before packaging in food-grade or pharmaceutical-grade containers for distribution

Industry Leadership

The global gelatin industry is led by established specialty ingredients companies with extensive production capabilities and diverse application portfolios. Key industry players include:

• Gelita AG

• Darling Ingredients Inc.

• Nitta Gelatin, Inc.

• Tessenderlo Group

• Weishardt

• Trobas Gelatine B.V.

• Lapi Gelatine S.p.a.

• Juncà Gelatines SL

• Italgel S.r.l

• Sterling Biotech Ltd.

• Gelnex

These companies serve diverse end-use sectors including food and beverages, pharmaceuticals, cosmetics, photography and imaging, technical and industrial uses, and biotechnology and research, demonstrating the broad market applicability of gelatin products.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Gelatin Manufacturing Plant DPR 2026: Machinery Cost, Capex/Opex, ROI and Raw Materials here

News-ID: 4379685 • Views: …

More Releases from IMARC Group

Australia Mining Equipment Market Projected to Reach USD 2.3 Billion by 2034

Market Overview

The Australia Mining Equipment Market reached a size of USD 1.5 Billion in 2025 and is forecasted to grow to USD 2.3 Billion by 2034. The market is projected to expand at a compound annual growth rate (CAGR) of 5.15% during the forecast period of 2026-2034. Growth drivers include increasing adoption of sustainable mining methods, emphasis on worker health and safety, and rising use of automated and remote-controlled mining…

Brazil Asset Management Market 2025 - Top Regions, Latest Technology, Investment …

The Brazil asset management market size reached USD 13,507.68 Million in 2024 and is projected to surge to USD 221,922.77 Million by 2033. The market is expected to grow at a CAGR of 36.48% during the forecast period from 2025 to 2033. The growth is driven by rapid digital transformation, technological innovation, and increasing adoption of environmental, social, and governance (ESG) principles. These factors have expanded product offerings and operational…

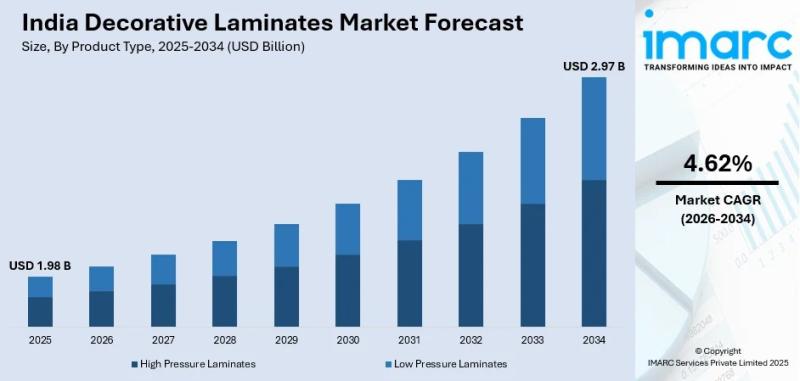

India Decorative Laminates Market to Reach USD 3.6 Billion by 2033, Growing at 6 …

Source: IMARC Group | Category: Construction & Manufacturing | Author Name: Gaurav

Report Introduction

According to IMARC Group's latest report titled "India Decorative Laminates Market Size, Share, Trends and Forecast by Product, Application, Texture, Pricing, Sector, and Region, 2025-2033", the market is witnessing substantial growth due to the booming real estate sector, rising disposable incomes, and the increasing preference for aesthetically appealing, durable, and low-maintenance surface solutions. The study offers a profound…

Australia Insulation Materials Market is Expected to Reach USD 4.01 Billion by 2 …

Market Overview

The Australia Insulation Materials Market was valued at USD 2.22 Billion in 2025 and is forecasted to reach USD 4.01 Billion by 2034. The market is expanding due to increased construction activity and a focus on energy efficiency across residential, commercial, and industrial sectors. Demand is driven by sustainable building practices, innovations in thermal and acoustic insulation, and supportive government incentives. Key market segments include polyurethane foam, which holds…

More Releases for Gelatin

Gelatin Market Set To boom | Market Trends, Expansion & Leading Companies |Gelit …

Market Size and Growth

The Global Gelatin Market size reached USD 2.6 billion in 2022 and is projected to witness lucrative growth by reaching up to USD 4.4 billion by 2030.

DataM Intelligence has released its latest research, "Gelatin Market Size 2025," providing a detailed overview of the industry. The report offers a deep dive into key market drivers, regional growth, and the competitive landscape, equipping businesses with the insights needed to…

Bovine Gelatin Market Insights: Current Status and Future Directions 2024 - 2031 …

Market Overview:

The bovine gelatin market is estimated to be valued at USD 1.40 Bn in 2024 and is expected to reach USD 2.23 Bn by 2031, exhibiting a compound annual growth rate (CAGR) of 6.9% from 2024 to 2031.

Market Dynamics:

The bovine gelatin market is expected to witness significant growth over the forecast period owing to the increasing demand from food and beverage industry. Gelatin is widely used in various food…

Medicinal Gelatin Market | El Nasr Gelatin, Ewald Gelatine, Gelita, Great Lakes …

The global medicinal gelatin market report is a comprehensive report that provides a detailed analysis of the current status and future trends of the medicinal gelatin market worldwide. This report provides valuable information to industry stakeholders by offering an in-depth perspective on market dynamics, competitive landscape, growth opportunities, and key challenges faced by industry participants.

From the perspective of market dynamics, this report explores the factors driving the growth of the…

Edible Gelatin Market | El Nasr Gelatin, Ewald Gelatine, Gelita, Great Lakes Gel …

The global edible gelatin market report is a comprehensive report that provides a detailed analysis of the current status and future trends of the edible gelatin market worldwide. This report provides valuable information to industry stakeholders by offering an in-depth perspective on market dynamics, competitive landscape, growth opportunities, and key challenges faced by industry participants.

From the perspective of market dynamics, this report explores the factors driving the growth of the…

Empty Capsules by Gelatin, Non-gelatin

Empty capsules are vital in the pharmaceutical, nutraceutical, and dietary_ supplement_ industries, providing a convenient and precise method for administering a variety of substances. They come in two primary forms: gelatin and non-gelatin, each tailored to meet specific requirements and preferences.

Download Free Sample PDF @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=319046

Gelatin capsules, often derived from animal sources like bovine or porcine collagen, have been a staple in the pharmaceutical industry for decades. They are known…

Gelatin Market Top Key Players, Industry Analysis And Forecast By 2027 | Xiamen …

The Gelatin market analysis includes market size, upstream situation, market segmentation, price & cost, and industry environment. In addition, the report outlines the factors driving industry growth and the description of market channels. The report begins with an overview of the industry chain structure and describes the upstream. Besides, the report analyses market size and forecast in different geographies, types, and end-use segments, in addition, the report introduces the Gelatin…