Press release

Disposable Syringe Manufacturing Plant Cost 2026: Feasibility Study and Profitability Insights

The global disposable syringe market represents a compelling investment opportunity driven by surging demand for safe and hygienic delivery of drugs, expansion in healthcare infrastructure, and growing demand for standardized, single-use medical devices. Disposable syringes are single-use medical injection devices that are presterilized, manufactured from medical plastic components comprising a graduated barrel, plunger, and needle. They are designed for the safe and controlled administration of precise fluid, vaccine, or medication dosages, guaranteeing accuracy, safety, and infection control while reducing the chance of cross-contamination.The market offers diverse product variants including insulin syringes, tuberculin syringes, hypodermic syringes, safety syringes, and auto-disable syringes, available in multiple capacities and different needle sizes to facilitate various clinical applications. These devices are compatible with automated filling systems, making them suitable for hospitals, clinics, diagnostic centers, and home healthcare applications. Their uniform design ensures consistent delivery performance across high-volume medical facilities and small healthcare practices alike.

Market Overview and Growth Potential

The global disposable syringe market demonstrates robust growth potential with strong fundamentals. The market was valued at USD 17.14 Billion in 2025 and is projected to reach USD 29.87 Billion by 2034, exhibiting a compound annual growth rate (CAGR) of 6.4% from 2026 to 2034.

This impressive growth trajectory is supported by expanding healthcare access, rising immunization coverage, and increasing demand for safe injection devices across urban and semi-urban regions. The Indian government allocated INR 99,858 crore (USD 11.50 billion) to the healthcare sector in the Union budget 2025-26, demonstrating substantial public investment in healthcare infrastructure that directly supports disposable syringe demand.

Key market drivers include the continuous growth in healthcare services where providers prioritize patient safety, regulatory compliance, and reliable single-use solutions. Additionally, ageing populations and higher incidence of chronic conditions have increased the need for regular injectable therapies. Government healthcare initiatives and improved distribution through organized procurement channels have further strengthened market penetration.

IMARC Group's report, "Disposable Syringe Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a plant. The disposable syringe manufacturing plant cost report offers insights into the process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Plant Capacity and Production Scale

The proposed disposable syringe manufacturing facility is designed with an annual production capacity ranging between 200-500 million units, enabling economies of scale while maintaining operational flexibility. This capacity range allows manufacturers to serve diverse market segments effectively, from large-scale institutional buyers to regional healthcare distributors.

The substantial production volume creates competitive advantages through:

• Optimized raw material procurement with better pricing power

• Efficient utilization of capital-intensive injection molding and sterilization equipment

• Lower per-unit production costs through economies of scale

• Enhanced market positioning to serve hospitals, clinics, pharmaceutical companies, diagnostic laboratories, vaccination centers, and the growing home healthcare sector

Financial Viability and Profitability Analysis

The disposable syringe manufacturing project demonstrates healthy profitability potential under normal operating conditions. Financial projections reveal attractive margins that make this venture particularly appealing for investors seeking stable returns in the healthcare sector.

Gross profit margins typically range between 45-55%, supported by stable demand and value-added applications. This strong gross margin reflects the essential nature of the product and the standardized pricing structure in institutional healthcare procurement.

Net profit margins are projected at 20-25%, indicating robust bottom-line performance after accounting for all operating expenses, depreciation, taxes, and other costs. These healthy margins provide cushion for market fluctuations and enable reinvestment in capacity expansion or technology upgrades.

The financial projections have been developed based on realistic assumptions related to capital investment, operating costs, production capacity utilization, pricing trends, and demand outlook. These projections provide a comprehensive view of the project's financial viability, return on investment (ROI), profitability, and long-term sustainability.

Request for a Sample Report:

https://www.imarcgroup.com/disposable-syringe-manufacturing-plant-project-report/requestsample

Operating Cost Structure

The operating cost structure of a disposable syringe manufacturing plant reveals clear cost drivers that require strategic management for optimal profitability.

Raw materials represent the largest component of operating expenses, accounting for approximately 45-55% of total OpEx. The primary raw material is medical-grade polypropylene (PP), which forms the core material for barrel and plunger components. Long-term contracts with reliable suppliers help mitigate price volatility and ensure consistent supply of materials.

Utilities account for 10-15% of operating expenses, covering electricity for injection molding machines and automated assembly lines, water requirements for plant operations, and steam for sterilization processes. Advanced monitoring systems and energy-efficient equipment can help optimize utility consumption.

Other operating expenses include packaging materials, transportation and logistics, salaries and wages for production and quality control staff, depreciation on machinery and equipment, taxes, and repair and maintenance costs. Optimizing processes and providing staff training can help control these operational costs effectively.

By the fifth year of operations, total operational costs are expected to increase substantially due to factors such as inflation, market fluctuations, and potential rises in the cost of key materials. Additional factors including supply chain disruptions, rising consumer demand, and shifts in the global economy may contribute to this increase.

Capital Investment Requirements

Establishing a disposable syringe manufacturing plant requires substantial capital investment across multiple categories:

Machinery Costs: Equipment represents the largest portion of total capital expenditure. Essential machinery includes:

• Plastic injection molding machines for barrel and plunger manufacturing

• Needle manufacturing and assembly units

• Sterilization systems to ensure product safety

• Automated inspection equipment for quality control

• Packaging and sealing machines

• Quality control laboratories with analytical instruments

All machinery must comply with industry standards for safety, efficiency, and reliability. The scale of production and automation level will determine the total cost of machinery.

Land and Site Development: The cost of land acquisition and site development, including charges for land registration, boundary development, and other related expenses, forms a substantial part of the overall investment. The location must offer easy access to key raw materials, particularly medical-grade PP. Proximity to target markets helps minimize distribution costs.

Civil Works: Construction costs include facility buildings designed to accommodate production lines, quality control areas, raw material storage, finished goods warehousing, and administrative offices. The site must have robust infrastructure including reliable transportation, utilities, and waste management systems.

Other Capital Costs: Additional investments include utilities setup, safety systems, environmental compliance equipment, initial working capital, and contingency reserves.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=8558&flag=C

Major Applications and Market Segments

Disposable syringes serve critical functions across multiple healthcare and industrial segments:

Healthcare and Medical Industry: Syringes are used during drug administration where accuracy of dosage, sterilization, and patient safety are paramount. The devices ensure safe administration of injectable drugs, vaccines, and biologics without the possibility of contaminant introduction.

Hospitals and Clinical Facilities: These institutions rely on disposable syringes for ease of use, infection control, and procedural efficiency in both inpatient and outpatient environments. Emergency and critical care services benefit from the accessibility, disposal ease, and reliability of disposable syringes.

Pharmaceutical and Biotech Industry: This sector depends on standardized injection devices for clinical trials, drug manufacturing, and distribution of injectable medications requiring precise dosing and sterility assurance.

Diagnostic and Laboratory Services: Proper fluid transfer and sample handling in diagnostic settings are made possible by the standardized use of syringes, supporting accurate test results.

Home Healthcare and Personal Use: Disposable syringes enable patients to accurately administer drugs to themselves using simple and safe medical devices, supporting the growing trend toward home-based care and chronic disease management.

Why Invest in Disposable Syringe Manufacturing?

Several strategic factors make disposable syringe manufacturing an attractive investment opportunity:

Public Health and Immunization Programs: Large-scale immunization programs require massive quantities of syringes where safety, sterility, and compliance with one-use standards are critical. Government vaccination initiatives create sustained demand.

Regulatory Compliance: Healthcare professionals are increasingly adopting safety-engineered and auto-disable syringes to reduce needle-stick injuries and infection risks. This regulatory push creates opportunities for manufacturers offering advanced product variants.

Technology Advantages: Innovations including low-dead-space designs and eco-conscious materials are supporting sustained market growth. Recent developments such as the EcoSafe safety syringe platform (launched October 2025) demonstrate ongoing product evolution that creates differentiation opportunities.

Market Standardization: The retail and medical supply sector enables distribution of injection devices that are both affordable and regulatory compliant, supporting consistent market demand through established procurement channels.

Localization Benefits: Establishing domestic manufacturing capabilities reduces import dependency, shortens supply chains, and enables faster response to regional healthcare needs. The introduction of Indonesia's first halal-certified syringe (July 2025) illustrates how localized production can serve specific market requirements.

Sustainable Entry Barriers: The need for specialized equipment, sterile production environments, regulatory approvals, and quality certifications creates barriers to entry that protect established manufacturers from excessive competition.

Buy Now: https://www.imarcgroup.com/checkout?id=8558&method=2175

Industry Leadership

The global disposable syringe industry is served by several established manufacturers with extensive production capacities and diverse application portfolios. Leading companies in this space include:

• Hindustan Syringes & Medical Devices Ltd

• NIPRO

• B.Braun SE

• BD

• Cardinal Health

These industry leaders serve critical end-use sectors including hospitals and clinics, pharmaceutical and biotechnology companies, diagnostic laboratories, vaccination centers, and the home healthcare sector. Their market presence demonstrates the viability and scale potential of disposable syringe manufacturing operations.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Services:

• Plant Setup

• Factoring Auditing

• Regulatory Approvals, and Licensing

• Company Incorporation

• Incubation Services

• Recruitment Services

• Marketing and Sales

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Disposable Syringe Manufacturing Plant Cost 2026: Feasibility Study and Profitability Insights here

News-ID: 4378645 • Views: …

More Releases from IMARC Group

Green Hydrogen Prices 2026: Trend Analysis, Fluctuations & Forecast

Global Green Hydrogen Prices have been closely monitored as the sector grows rapidly with the energy transition. The Green Hydrogen Price Index reflects evolving costs influenced by renewable energy availability, electrolyzer efficiency, and regional market demand. Rising adoption in industrial, transportation, and clean energy applications has intensified interest in price trends, historical data, and future forecasts, making reliable pricing intelligence essential for investors, producers, and buyers worldwide.

Green Hydrogen Current Price…

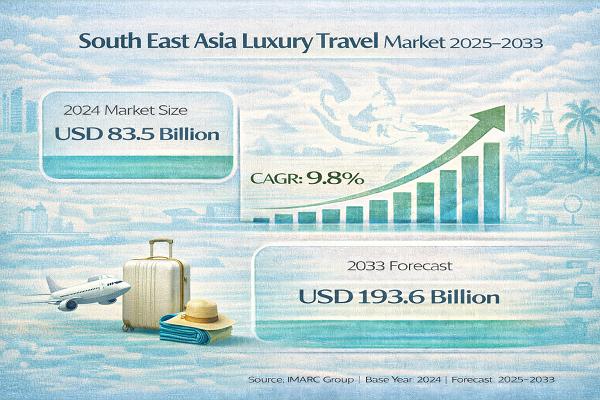

Southeast Asia Luxury Travel Market to Reach USD 193.6 Billion by 2033, Growing …

South East Asia Luxury Travel Market : Report Introduction

According to IMARC Group's report titled "South East Asia Luxury Travel Market Research Report and Industry Forecast" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Note : We are in the process of updating our reports to cover the 2026-2034 forecast period. For the most recent data, insights, and industry updates, please click on…

Drug Manufacturing Plant Cost 2026: Detailed Project Report and Raw Material Req …

The Drug Manufacturing Plant Project Report 2026 provides a detailed market and feasibility analysis for establishing a modern pharmaceutical drug manufacturing facility. A "drug" refers to a chemical or biological substance used to diagnose, treat, cure, prevent, or manage diseases and health conditions. Drugs encompass a broad range of forms - including tablets, injections, creams, and inhalers - and must undergo rigorous testing and regulation to ensure safety and effectiveness.…

Global Dental Cement Market Size projected to Reach USD 1,212.8 Million by 2033 …

Market Overview

The global dental cement market size was valued at USD 664.6 Million in 2024 and is projected to reach USD 1,212.8 Million by 2033, growing at a CAGR of 6.9% during the forecast period 2025-2033. The market expansion is driven by the rising prevalence of dental disorders, advancements in cement technology enhancing product quality, and the increasing popularity of cosmetic dentistry. These factors collectively boost the demand for effective…

More Releases for Disposable

Disposable Medical Sensors Market: Advancing Patient Monitoring with Cutting-Edg …

"In recent years, the global Disposable Medical Sensors Market has witnessed a dynamic shift, influenced by changing consumer preferences, technological advancements, and a growing emphasis on sustainability. The Research report on Disposable Medical Sensors Market presents a complete judgment of the market through strategic insights on future trends, growth factors, supplier landscape, demand landscape, Y-o-Y growth rate, CAGR, pricing analysis. It also provides and a lot of business…

Disposable Incontinence Products Market: "Disposable Incontinence Products to Re …

Disposable Incontinence Products Market Scope:

Key Insights : Disposable Incontinence Products Market size was valued at USD 12.4 billion in 2022 and is poised to grow from USD 13.33 billion in 2023 to USD 23.77 billion by 2031, growing at a CAGR of 7.50% during the forecast period (2024-2031).

Access the full 2024 Market report for a comprehensive understanding @https://www.skyquestt.com/report/disposable-incontinence-products-market

In-Depth Exploration of the global Disposable Incontinence Products Market: This report…

Disposable Medical Stopcock Market Streamlining Healthcare: The Advantages of Di …

Disposable Medical Stopcock Market worth $1.51 Bn by 2031 - Exclusive Report by InsightAce Analytic Pvt. Ltd.

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global Disposable Medical Stopcock Market by Type (4-Way Stopcock, 3-Way Stopcock, 2-Way Stopcock, And Others) By Application (Hospitals, Clinics, Others), Trends, Industry Competition Analysis, Revenue and Forecast To 2031."

According to the latest research by InsightAce Analytic, the Global Disposable Medical…

Know Everything About Disposable Blood Bag: Importance of Disposable Blood Bag

Systems for collecting, storing, transporting, and transfusing human blood and products obtained from it are available as disposable biomedical goods called blood bag systems. Hospitals, blood banks, government initiatives, and NGOs all use disposable blood bags to store blood donations that have been received.

To reduce the importation of blood components from Western nations, government-funded programs in some Asian countries are concentrating on developing blood separation technology. The need for blood…

Disposable Toothbrush Market

Disposable toothbrush

Disposable toothbrush is usually smaller in size, cheaper, and used only once before it is discarded. Usually, it comes in pre-pasted form with the toothpaste already on the toothbrush in smaller quantities. All one need is water to activate the paste and start using it.

This type of toothbrush is perfect for traveling, camping, military, airlines, and hospitality. The disposable toothbrush is also good for those who have braces. Choosing…

Disposable Nitrile Gloves Market analysis report- with Leading players, Applicat …

Disposable Nitrile Gloves Market

The Disposable Nitrile Gloves Market is defined by the presence of some of the leading competitors operating in the market, including the well-established players and new entrants, and the suppliers, vendors, and distributors. The report also analyzes the development proposals and the feasibility of new investments. The Disposable Nitrile Gloves Market report has been collated in order to provide guidance and direction to the companies and individuals interested…