Press release

Drug Manufacturing Plant Cost 2026: Detailed Project Report and Raw Material Requirements

The Drug Manufacturing Plant Project Report 2026 provides a detailed market and feasibility analysis for establishing a modern pharmaceutical drug manufacturing facility. A "drug" refers to a chemical or biological substance used to diagnose, treat, cure, prevent, or manage diseases and health conditions. Drugs encompass a broad range of forms - including tablets, injections, creams, and inhalers - and must undergo rigorous testing and regulation to ensure safety and effectiveness.Increasing healthcare needs, rising incidences of chronic diseases, and rapid advancements in biotechnology and biopharmaceuticals are driving demand in the drug manufacturing sector. This trajectory is rooted in global healthcare expansion, where both developed and emerging economies are investing in self-sufficiency and local production capacities. The drug manufacturing industry's relevance continues to rise as populations age and healthcare access expands globally.

This report serves as a critical resource for investors and entrepreneurs who seek a data-backed, actionable roadmap to establish a pharmaceutical manufacturing operation - detailing everything from production processes and capacity planning to financial projections and operating costs.

Market Overview and Growth Potential

The global drug industry is expanding steadily, propelled by technological innovation, enhanced healthcare access, and the sustained rise in chronic diseases such as diabetes and heart disease. The report emphasizes key dynamics that bolster industry growth, including:

• Rising Global Healthcare Demand: An aging population and increased longevity are creating greater demand for therapeutic drugs and treatment solutions.

• Biotechnology Advancements: Novel drug delivery systems, biologics, and personalized medicines are opening new market segments and increasing production value.

• Expanding Manufacturing Hubs: Regions such as Asia-Pacific - particularly India and China - are emerging as significant manufacturing hubs due to competitive infrastructure and lower production costs.

While the report does not disclose overall market valuation figures in the public summary, its qualitative insights point to sustained long-term demand growth, backed by demographic trends and relentless healthcare requirements across populations.

IMARC Group's report, "Drug Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," offers a comprehensive guide for establishing a plant. The drug manufacturing plant cost report offers insights into the process, financials, capital investment, expenses, ROI, and more for informed business decisions.

Plant Capacity and Production Scale

According to the feasibility report, the proposed drug manufacturing facility is designed with an annual production capacity of approximately 500 million tablets. This scale allows for economies of scale - reducing per-unit production costs - while maintaining operational flexibility to adapt to market demand fluctuations.

The report outlines unit operations involved in drug production, including formulation, blending, granulation, tablet compression, coating, filling, and packaging. These stages form a comprehensive production ecosystem capable of supporting diversified pharmaceutical product lines.

Financial Viability and Profitability Analysis

The drug manufacturing project demonstrates strong profitability potential with robust margin projections:

• Gross Profit Margins: Typically 55-65%

• Net Profit Margins: Approximately 25-35%

These profit ranges reflect stable demand conditions and the value-added nature of pharmaceutical products, positioning drug manufacturing as financially compelling for investors.

The report provides comprehensive financial projections, including income and expenditure forecasts, ROI (Return on Investment), and Net Present Value (NPV) assessments. These projections are built on realistic assumptions related to capital investments, operating costs, pricing trends, and production utilization.

Request for a Sample Report: https://www.imarcgroup.com/drug-manufacturing-plant-project-report/requestsample

Operating Cost Structure

The operating expense (OpEx) breakdown highlights the primary cost drivers in a drug manufacturing operation:

• Raw Materials: Approximately 40-50% of total OpEx (predominantly APIs - Active Pharmaceutical Ingredients)

• Utilities: Around 20-25% of OpEx (including power, water, steam)

Other expenses such as transportation, packaging, salaries, depreciation, taxes, and maintenance are recognized as part of OpEx, though exact percentages for these costs are only available in the full report. Strategic sourcing of APIs, efficient utility management, and packing optimization are essential to controlling costs in operation.

Capital Investment Requirements

The drug manufacturing project involves significant capital investments across multiple categories. While detailed numbers are provided only in the full report, the public summary outlines the critical investment areas:

Land and Site Development:

• Land acquisition - location selection based on access to raw materials and utilities.

• Site preparation including roads, drainage and zoning compliance.

Civil Works:

• Construction of production facilities, quality control labs, storage areas, and administrative buildings.

Machinery and Equipment:

Essential production machinery includes:

• Bioreactors or chemical synthesis reactors

• Filtration and purification systems

• Drying units

• Granulators and tablet presses

• Capsule fillers

• Coating machines

• Automated packaging and labeling lines

These capital elements form the backbone of an efficient and compliant drug production plant.

Major Applications and Market Segments

Drug manufacturing serves several critical applications:

• Active Pharmaceutical Ingredient (API) Production - custom reactors and processing systems for biological and chemical APIs.

• Formulation & Compounding - mixing, granulation, and blending of solid, liquid, and semi-solid dosage forms.

• Sterile Manufacturing - aseptic filling lines and controlled environments for injectable drugs.

• Packaging & Labeling - blister packaging, vial filling, serialization, and tamper-evident systems.

These segments address diverse pharmaceutical requirements across healthcare systems.

End-use industries include hospitals, clinics, pharmacies, biotech firms, and broader healthcare supply channels that depend on a steady supply of quality medications.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=22211&flag=C

Why Invest in Drug Manufacturing?

The drug manufacturing industry exhibits several compelling investment drivers:

• Growing Healthcare Demand: Chronic disease prevalence and aging populations sustain long-term drug demand.

• Technological Advancements: Biologics and innovative drug delivery systems feed new market opportunities.

• Government Support: Many governments invest in healthcare infrastructure, support local production, and encourage self-sufficiency in pharmaceuticals.

• Regulatory Standards: Good Manufacturing Practices (GMP) ensure quality and sustainability across drug production processes.

These factors enhance the strategic importance of drug manufacturing as both a growth-oriented and socially impactful investment.

Industry Leadership

The report identifies major multinational pharmaceutical manufacturers serving healthcare, hospitals, clinics, pharmacies, and biotechnology sectors. Key examples include:

• Pfizer Inc.

• Johnson & Johnson

• Novartis AG

• Bristol-Myers Squibb

• GSK (GlaxoSmithKline)

These industry leaders exemplify diverse production portfolios and global market reach.

Buy Now: https://www.imarcgroup.com/checkout?id=22211&method=2175

Conclusion

Establishing a drug manufacturing plant in 2026 presents a strong investment opportunity underpinned by enduring healthcare demand, favorable profit margins, and broad application segments.

Strategic planning across capital investments, facility development, quality systems, and operational cost control - all detailed in the full feasibility report - can help prospective investors convert vision into a sustainable and profitable manufacturing enterprise.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Services:

• Plant Setup

• Factoring Auditing

• Regulatory Approvals, and Licensing

• Company Incorporation

• Incubation Services

• Recruitment Services

• Marketing and Sales

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Drug Manufacturing Plant Cost 2026: Detailed Project Report and Raw Material Requirements here

News-ID: 4378597 • Views: …

More Releases from IMARC Group

Global Dental Cement Market Size projected to Reach USD 1,212.8 Million by 2033 …

Market Overview

The global dental cement market size was valued at USD 664.6 Million in 2024 and is projected to reach USD 1,212.8 Million by 2033, growing at a CAGR of 6.9% during the forecast period 2025-2033. The market expansion is driven by the rising prevalence of dental disorders, advancements in cement technology enhancing product quality, and the increasing popularity of cosmetic dentistry. These factors collectively boost the demand for effective…

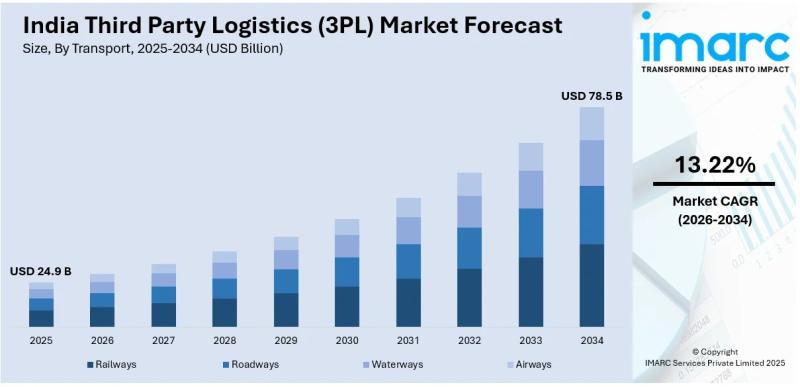

India Third Party Logistics (3PL) Market Forecast 2026-2034: Growth & Supply Cha …

According to IMARC Group's report titled "India Third Party Logistics (3PL) Market Size, Share, Trends and Forecast by Transport, Service Type, End Use, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

India Third Party Logistics (3PL) Market Outlook

India third party logistics (3PL) market size reached USD 24.9 Billion in 2025 and is expected to reach USD 78.5 Billion by…

Global Specialty Paper Market Edition 2025: Industry Size to Reach 48.7 Billion …

Market Overview

The global specialty paper market size reached 36.7 Billion Metric Tons in 2024 and is projected to reach 48.7 Billion Metric Tons by 2033, growing at a CAGR of 3.17% during the forecast period 2025-2033. Market growth is driven by rising demand for eco-friendly, sustainable packaging solutions, especially in food, beverage, personal care, and retail sectors. Innovations in printing and packaging technologies and increased adoption in e-commerce further support…

Global Satellite Communication (SATCOM) Market Report 2025: Size Projected USD 1 …

Market Overview

The global Satellite Communication (SATCOM) Market was valued at USD 92.15 Billion in 2024 and is expected to reach USD 184.7 Billion by 2033. The market is projected to grow at a CAGR of 7.63% during the forecast period 2025-2033. Growth is driven by rising demand for internet in remote areas, military communications, broadcasting services, and satellite technology for disaster management.

Study Assumption Years

• Base Year: 2024

• Historical Year/Period: 2019-2024

• Forecast Year/Period: 2025-2033

Satellite…

More Releases for Manufacturing

Manufacturing the Future: Exploring the In-Space Manufacturing Market

Rapid improvements in space technology have created new opportunities for in-space production, transforming the space sector. The in-space manufacturing sector is expanding rapidly as space agencies and private companies investigate ways to manufacture products and structures in space. According to MarketsandMarkets' thorough market research analysis, the worldwide in-space manufacturing market is predicted to expand significantly in the next years. In this blog article, we will evaluate the recent trends and…

Global Miscellaneous Market by Types (Gasket, Packing, and Sealing Device Manufa …

The global Miscellaneous market was valued at xx million in 2020 and is projected to reach US$ xx million by 2027, at a CAGR of xx% during the forecast period.

Global Miscellaneous Market overview

Miscellaneous Market research report offers great insights into the market and consumer data and their interpretation through various figures and graphs.

Miscellaneous markets have experienced significant growth in recent years. The main reason for this is the increasing…

Smart Factory Transforming from “Manufacturing” to “Intelligent Manufactur …

The concept of “Industry 4.0” was officially announced by the German government in 2013 at the Hannover Messe. Since then, its influence has taken the world by storm. From steam mechanization to power automation to data informatization, the Industry 4.0, driven by “intelligentization”, will completely subvert the expectations, changing perceptions of productivity and production relations in the traditional manufacturing industry by way of qualitative change – an immortal monument, perhaps,…

Additive & Conventional Manufacturing – Hybrid Manufacturing Techniques From C …

Croft Filters, based in Warrington, England, have been supplying custom filtration and separation solutions for over 31 years. Over this time, Croft has developed a reputation for their quality, bespoke service through manufacturing a variety of products for specific requirements. These products have included Filtration Cones, Baskets & Screens, Disc Filters and Filtration Housings amongst others, and they are made with Wire Mesh, Wedge Wire and Perforated Plate, depending on…

Digital Meter Market 2017 - Al-Jon Manufacturing, Environmental Manufacturing, H …

The Global Digital Meter Market 2017 Industry Research Report focused on global and regional market, major manufacturers, as well as the current state of the Digital Meter industry. First, "Global Digital Meter Industry 2017" report analyzed the basic scope of this industry like definition, specification, classification, application, industry policy, news analysis and Digital Meter industry chain structure.

Major Companies Covered in this report:-

Al-Jon Manufacturing

Heitman Laboratories

Kws Manufacturing Company

Kmb Systems

Obvius Holdingd Llc

Lubecorp Manufacturing

Quadlogic…

Competitive Segmentation of Global Mixed-mode Manufacturing Market 2016 Industry …

The market research report titled Mixed-mode Manufacturing Market Research Report 2016 provides a detailed overview of the global Mixed-mode Manufacturing market, in terms of crucial market factors such as the demand drivers, challenges, market segments, key companies, and the recent market trends. The quantitative and the qualitative information presented in this research study is based on primary and secondary sources of information. Moreover, much of the information contained in this…