Press release

Inside the Ceramic Filler Revolution: Trends, Margins & Investment Signals

Ceramic filler powder: inorganic additives used to enhance mechanical, thermal, and electrical properties in polymers, coatings, adhesives, rubber, and composites.Widely applied in automotive, electronics, construction, aerospace, and consumer goods.

Positioned as a high-performance functional filler that improves dimensional stability and wear resistance.

Market Size (2024): USD 2,453 million.

Market Size (2031): USD 3,831 million

Expected CAGR: 6.6% through 2031.

Average global price benchmark: USD 500/ton.

Strong correlation between industrial automation growth and filler adoption.

Adoption spiraling in advanced composites and heat-dissipating materials.

Global Industry Snapshot

Total Estimated Units Sold Globally (2024): 49,051 ton

Cost of Goods Sold (COGS) per unit average: USD 350/ton.

Raw materials: 65% of COGS.

Energy & utilities: 18%.

Labor & overhead: 12%.

Packaging/handling: 5%.

Factory Gross Profit per Quantity: USD 150/ton.

Factory Gross Margin: 30%.

Typical Full Machine Production Capacity per Line: 5,000 Ton/year

Downstream Industry Demand Breakdown (% of ceramic filler usage):

Polymer composites & plastics: 32%.

Coatings & paints: 22%.

Rubber & elastomers: 18%.

Construction materials: 12%.

Electronics & semiconductors: 9%.

Others (adhesives, sealants): 7%.

Latest Trends and Technological Developments

2025-Jan-15: Development of nano-engineered ceramic fillers enabling enhanced conductivity for thermal interface materials.

2025-Nov-02: Launch of bio-derived ceramic filler blends reducing carbon footprint in automotive composites.

Rise in surface functionalization tech to improve filler-matrix bonding at lower loadings.

Adoption of AI-assisted process control improving milling and powder uniformity.

Increased investment in ultra-fine particle systems for high-performance electronic applications.

Asia Regional Insights

Asia remains the largest regional market for ceramic fillers by volume and value.

China: dominant production base with high export orientation.

Japan & South Korea: focus on advanced engineered grades for electronics and automotive.

India: rapid industrialization increasing demand in construction composites and polymer sectors.

Key regional drivers:

Electrification of vehicles.

Demand for lightweight materials.

Expansion of electronics manufacturing hubs.

Growth momentum also driven by government incentives for manufacturing and export.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/5787653

Ceramic Filler Powder by Type:

Alumina Based Fillers

Silica Fillers

Titania Fillers

Others

Ceramic Filler Powder by Product Category:

Micron Sized Powders

Sub Mircon Powders

Nano Sized Powders

Ceramic Filler Powder by Market Segment:

Thermal Management Fillers

Insulation Fillers

Reinforcement Fillers

Cost Optimizing Fillers

Others

Ceramic Filler Powder by Features:

High Thermal Conductivity

Electrical Insulation

Flame Retardancy

Wear Resistance

Others

Ceramic Filler Powder by Usage:

Construction Composites

Automotive Lightweight Components

Rubber Compounding

Others

Ceramic Filler Powder by Application:

Polymer Compounds and Plastics

Coatings and Paints

Adhesives and Sealants

Others

Global Top 30 Key Companies in the Ceramic Filler Powder Market

3M Company (Minnesota, US)

Saint Gobain (Courbevoie, France)

Henkel (Dusseldorf, Germany)

Momentive (New Yotk, US)

Showa Denko Materials (Tokyo, Japan)

Imerys (Paris, France)

CeramTec (Plochingen, Germany)

H.C.Starck (Goslar, Germany)

Sumitomo Chemical (Tokyo, Japan)

Mitsubishi Chemical Group (Tokyo, Japan)

CoorsTek Inc (Colorado, US)

Kyocera (Kyoto, Japan)

Krosaki Harima (Kitakyushu, Japan)

Tosoh Corporation (Tokyo, Japan)

Murata Manufacturing (Kyoto, Japan)

Carborundum Universal Ltd (Chennai, India)

Zibo Ceramic Filler Ball Manufacturers (Zibo, China)

Changzhou Konada New Materials Technology (Changzhou, China)

BASF SE (Ludwigshafen, Germany)

Heraeus Group (Hanau, Germany)

Tokuyama Corporation (Shunan, Japan)

Solvay S.A. (Brussels, Belgium)

Albemarie Corporation (North Carolina, US)

CRC Evans (Aberdeenshire, UK)

Shin Etsu Chemical Co., Ltd (Tokyo, Japan)

Clariant AG (Muttenz, Sitzerland)

Morgan Advanced Materials plc (Windsor, UK)

NGK Insulators, Ltd (Nagoya, Japan)

Toshiba Material Co., Ltd. (Tokyo, Japan)

AlzChem Group Ag (Trostberg, Germany)

Regional Insights

Southeast Asia (ASEAN) showing above-average growth due to manufacturing shift from China.

Indonesia:

Growing usage in automotive parts and building materials.

Increased industrialization and infrastructure investments.

Vietnam and Thailand:

Emerging as fill production + export hubs.

Supports regional electronics and consumer goods industries.

ASEAN demand largely from plastics, rubber, and construction sectors.

Industry Challenges

Volatility in raw material prices (alumina, silica, kaolin).

Energy cost fluctuations impacting COGS.

Quality control complexity in ultra-fine and nano grades.

Environmental compliance and emissions standards.

Supply chain risks with geopolitical trade barriers.

Strategic Insights

Vertical integration of mining and filler processing improves margins.

Partnerships with automotive and electronics OEMs secure long-term offtake.

Investment in R&D for lighter, higher-performance fillers.

Expansion of production facilities near end-use clusters (SE Asia).

Adoption of digital supply chain systems to mitigate disruption risks.

Product Models

Ceramic filler powders are engineered inorganic particulate materials added to polymers, coatings, adhesives, and composites to improve mechanical strength, thermal stability, electrical insulation, and dimensional control.

Alumina-Based Fillers are ceramic powders known for high hardness, excellent thermal resistance, and good electrical insulation, making them ideal for high-performance composites, coatings, and thermal management applications in electronics and engineering plastics. Notable products include:

3M Alumina Ceramic Filler HC-500 3M Company (High): Premium high-purity alumina powder with superior thermal stability, used by OEMs for advanced polymers and high-temp composites; ~$1530/kg.

Momentive Alumina Nanopowder MN-A2 Momentive (Middle): Submicron alumina for thermal interface materials in power electronics; ~$815/kg.

Showa Denko A-Fine Al2O3 - Showa Denko Materials (Middle): Balanced purity alumina for coating and structural resin applications; ~$6-12/kg.

H.C. Starck Alumina Micro-Powder - H.C.Starck (Low): Cost-effective alumina offering basic thermal/electrical performance; ~$2-5/kg.

Sumitomo Chem Alumina Filler SC-A1 Sumitomo Chemical (Low): General use alumina for adhesives and sealants; ~$2.54.5/kg.

Silica Fillers provide low thermal expansion, good chemical stability, and insulating properties. Notable products include:

Showa Denko Fused SiO2 SD-300 - Showa Denko Materials (Middle): Mid-range fused silica for coatings; ~$7-13/kg.

Mitsubishi Chem Silica Blend MB-Si5 - Mitsubishi Chemical Group (Low): Entry silica for plastics and elastomers; ~$2-4/kg.

HP High-Purity Fused Silica Filler - Jiangsu Shengtian New Material Co., Ltd.: A high-purity silica powder for advanced ceramics & electronic packaging; ideal for high performance applications. (High segment; ~US$10001500/ton)

Fused Silica for Resin Filler Lianyungang Chemsize: Silica powder for resin and polymer filler applications, balancing performance and cost. (Mid segment; ~US$500750/ton)

Superior Fused Silica Flour for Thermal Ceramic Chemsize Intl: Thermal-grade silica for insulating ceramics and refractory mixes. (Mid segment; ~US$600900/ton)

Titania Fillers add refractive index control, UV resistance, and enhanced mechanical strength. They are used in coatings, pigments, high-temperature composites, and specialized ceramic applications. Notable products include:

Titanium Dioxide R-996 High-Quality Powder Jar Hing Products: Premium TiO2 for advanced ceramics & coatings with excellent brightness. (High segment; ~US$2000-2100/ton)

R-996 Titanium Dioxide Rutile Powder - Qingdao Tianyi Titanium Industry Co., Ltd.: High-brightness TiO2 rutile filler with excellent dispersibility for coatings and plastics. (High segment; ~US$1,900-2,200/ton)

Nano TiO2 Powder (high-purity) - SAT NANO: Nano particulate titanium dioxide with strong optical and photocatalytic properties, used in advanced material applications. (High segment; ~US$2,000-2,500/ton)

Tinox A-2380 Uncoated Titanium Dioxide Anatase - TINOX: Universal anatase TiO2 filler suited for rubber, paper, and masterbatch. (High segment; ~US$1,800-2,200/ton)

Titanium Dioxide R-213 White Powder - BioTio: Industrial TiO2 rutile powder with good hiding power and compatibility in coatings, paper and plastics. (Mid segment; ~US$1,0001,500/ton)

Investor Takeaways

Ceramic filler market poised for multi-year growth driven by composites demand.

Stable price and margin structure (30% gross margin).

High utilization of production capacity in key Asian hubs.

Technological advancements create premium product tiers with higher margins.

ASEAN markets, including Indonesia, represent rapidly expanding demand pockets.

Investor Analysis

This report provides investors with clear quantitative and qualitative insight into the Ceramic Filler Powder industrys size, growth trajectory, cost structure, and regional dynamics especially in Asia and Southeast Asia. Understanding price benchmarks, cost breakdowns, capacity metrics, and industry trends enables better capital allocation, risk assessment, and identification of growth levers. By highlighting technological evolution and downstream demand distribution, investors can spot opportunities in high-growth segments and geographies, ultimately aiding portfolio strategy and competitive positioning.

Request for Pre-Order Enquiry On This Report

https://www.qyresearch.com/customize/5787653

5 Reasons to Buy This Report

Comprehensive quantification of market size and growth through 2031.

Detailed cost structure and margin analysis per unit.

Regional focus on Asia & ASEAN with Indonesia data insights.

Coverage of latest technological trends shaping industry direction.

Strategic guidance and investor-centric takeaways.

5 Key Questions Answered

What is the current size and forecast of the global ceramic filler powder market?

How are costs and margins structured in global production?

Which regions and countries show the fastest growth?

What technological advancements are disrupting the market?

Who are the leading industry players and what are their competitive strengths?

Chapter Outline

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Related Report Recommendation

Global Ceramic Filler Powder Market Research Report 2026

https://www.qyresearch.com/reports/5787653/ceramic-filler-powder

Global Ceramic Filler Powder Sales Market Report, Competitive Analysis and Regional Opportunities 2026-2032

https://www.qyresearch.com/reports/5787651/ceramic-filler-powder

Ceramic Filler Powder- Global Market Share and Ranking, Overall Sales and Demand Forecast 2026-2032

https://www.qyresearch.com/reports/5787652/ceramic-filler-powder

Global Ceramic Filler Powder Market Outlook, InDepth Analysis & Forecast to 2032

https://www.qyresearch.com/reports/5787655/ceramic-filler-powder

Global Ceramic Filler Market Research Report 2025

https://www.qyresearch.com/reports/4157095/ceramic-filler

Global Prosthetic Ceramic Fillers Market Research Report 2025

https://www.qyresearch.com/reports/4262873/prosthetic-ceramic-fillers

Global Thermally Conductive Ceramic Filler Market Research Report 2025

https://www.qyresearch.com/reports/3491841/thermally-conductive-ceramic-filler

Global Ceramic Powder Market Research Report 2026

https://www.qyresearch.com/reports/5573381/ceramic-powder

Global Special Ceramic Powder Market Research Report 2026

https://www.qyresearch.com/reports/5848367/special-ceramic-powder

Global Zirconia Ceramic Powder Market Research Report 2026

https://www.qyresearch.com/reports/5866944/zirconia-ceramic-powder

Contact Information:

Tel: +1 626 2952 442 (US) ; +86-1082945717 (China)

+62 896 3769 3166 (Whatsapp)

Email: willyanto@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Inside the Ceramic Filler Revolution: Trends, Margins & Investment Signals here

News-ID: 4377359 • Views: …

More Releases from QY Research

Top 30 Indonesian Light Bulbs Public Companies Q3 2025 Revenue & Performance

1) Overall companies performance (Q3 2025 snapshot)

Signify (Euronext: LIGHT) global lighting leader with presence in Indonesia (Philips brand).

PT Maspion Holdings Corporation Tbk Conglomerate with electronics/LED potential.

PT Sat Nusapersada Tbk Electronics/assembly supplier.

PT Supreme Cable Manufacturing & Commerce Tbk Electrical cable maker (components).

PT KMI Wire and Cable Tbk Wire and cable supplier.

PT Voksel Electric Tbk Cable/electrical parts.

PT Erajaya Swasembada Tbk…

The Future of Sustainable Barrier Packaging: Trends, Players, and Market Forecas …

High Barrier PCR Packaging Film refers to multilayer flexible films incorporating Post-Consumer Recycled (PCR) polymers engineered with high barrier properties against oxygen, moisture, light, and contaminants. These films are increasingly used in food, pharmaceutical, personal care, and select non-food packaging due to sustainability mandates and extended shelf-life requirements.

Combines recycled resin integration with high barrier protection for packaging demanding long shelf life and integrity.

Essential in markets transitioning toward circular…

Smart At-Home Beauty: Market Drivers, Unit Economics, and Top Players

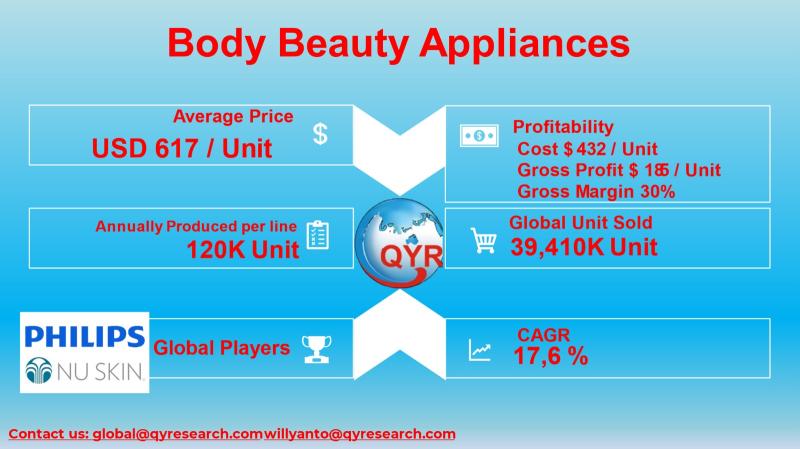

Body Beauty Appliances refers to consumer and professional devices designed for body hair removal, contouring, skin tightening, massage, cellulite reduction, and other body aesthetic/routine applications using technology such as LED, RF, laser, ultrasound, micro-current.

The industry integrates personal care, wellness, and beauty tech, bridging cosmetic enhancement with at-home convenience.

Global market drivers include increasing self-care routines, rising disposable incomes, digital/social commerce growth, and demand for non-invasive solutions.

Social media and influencer culture are…

Market Overview - Silicone Ablative Material

QY Research has recently published a comprehensive market study on Silicone Ablative Material, a class of high-performance thermal protection materials designed to withstand extreme heat flux, aerodynamic shear, and oxidative environments through controlled surface ablation. Silicone ablative materials are critical for aerospace and defense applications, including rocket motor insulation, re-entry heat shields, hypersonic vehicles, and solid rocket nozzles, where sacrificial thermal protection ensures structural integrity.

The market is transitioning from legacy…

More Releases for Filler

Thermoplastic Filler Market Size Analysis by Application, Type, and Region: Fore …

USA, New Jersey- According to Market Research Intellect, the global Thermoplastic Filler market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The Thermoplastic Filler Market is experiencing steady growth, driven by increasing demand across industries such as automotive, construction, and packaging. These fillers are widely used…

FITI Announces October Botox & Filler Training

Miami, FL - Florida International Training Institute (FITI) [https://fitischools.edu/fiti-health-and-aesthetics/] is thrilled to announce its upcoming aesthetic education courses for October 2024, offering specialized training in Botox injections and dermal fillers. These highly anticipated sessions provide healthcare professionals with hands-on experience in advanced techniques, ensuring they stay ahead in the cosmetic medicine field.

October 2024 Course Schedule:

*

Friday, Oct 18, 2024, 8:00 AM - Beginner Botox Training. Sold Out.

*

Saturday, Oct 19,…

October Filler & Botox Training for Physicians

Miami, FL - Florida International Training Institute (FITI) is excited to announce our next Advanced Filler & Botox Training for Licensed Physicians [https://training.fitihealthaesthetic.com/] on October 18, 2024. Following the success of our sold-out September session, this highly sought-after continuing education course offers a unique opportunity for medical professionals to enhance their expertise in the rapidly growing field of cosmetic medicine.

About the Course

This advanced training program is designed exclusively for licensed…

Two-Dosage Filler Liquid Thermal Gap Filler market: Promising Regions for Compan …

"The Two-Dosage Filler Liquid Thermal Gap Filler global market is thoroughly researched in this report, noting important aspects like market competition, global and regional growth, market segmentation and market structure. The report author analysts have estimated the size of the global market in terms of value and volume using the latest research tools and techniques. The report also includes estimates for market share, revenue, production, consumption, gross profit margin, CAGR,…

AMA Beffi Dew Filler | JNL

JNL Co., Ltd. is a beauty device manufacturer that specializes in medical beauty devices, fillers, and functional cosmetics. Representing the level of the industry in Korea, JNL's excellence in beauty device technology is widely promoted across the world through the export of beauty devices, exporting its superb products with Cosmeceutical, Beffi Dew AMA Filler, and Home Care Devices.

JNL AMA Beffi Dew Filler

Beffi Dew Filler is an injection with hyaluronic acid…

Beffi Dew Filler Beauty, Star AMA FILLER Bringing You Natural Beauty | JNL

JNL Co., Ltd. is a beauty device manufacturer that specializes in medical beauty devices, fillers, and functional cosmetics. JNL is exporting its superb products with Beffi Dew AMA Filler and home care devices to over 61 countries worldwide.

Beffi Dew Beauty AMA Filler

This is not only a product of a popular line within the Beffi Dew Filler Product Line, but also this is a product with high viscosity that has…