Press release

Global Aerospace 3D Printing Market Analysis 2025-2035: Trends, Drivers, Opportunities, and Regional Insights

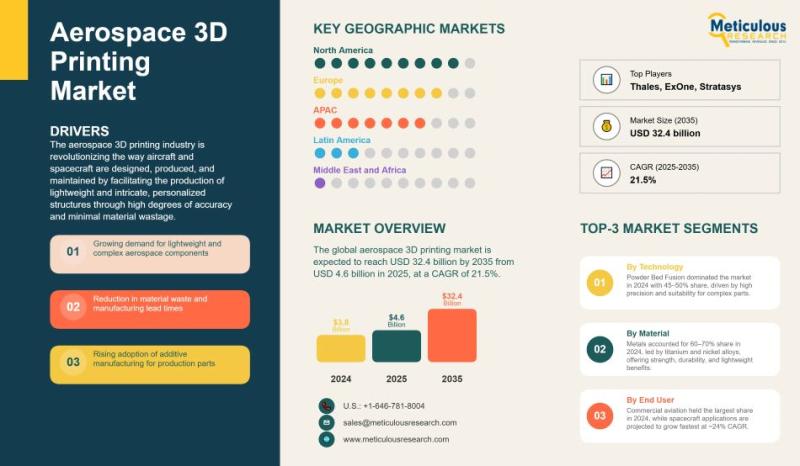

Aerospace 3D printing is reshaping aircraft and spacecraft manufacturing with lightweight, complex, and efficient components.

Download Sample Report Here: https://www.meticulousresearch.com/download-sample-report/cp_id=6244

Why 3D Printing Fits Naturally into Aerospace Manufacturing

Traditional machining removes material. Additive manufacturing builds only what is required. This simple difference has massive implications in aerospace, where weight, precision, and material efficiency are critical. Engineers are now able to design parts that were previously impossible to produce. Complex internal channels, lattice structures, and integrated components can be manufactured as a single unit rather than assembling multiple pieces. This reduces failure points, improves durability, and cuts down material waste significantly. Applications range from structural brackets and turbine components to cabin parts and satellite structures, covering both prototyping and end-use parts.

Market Structure: Collaboration Between Aerospace and Additive Specialists

The competitive landscape shows a blend of aerospace manufacturers, advanced production firms, and additive manufacturing experts. Instead of working in isolation, these players are forming partnerships and integrating additive manufacturing directly into assembly and production environments. The focus is no longer limited to prototypes. The shift is clearly toward serial production and operational use.

Driver: Pressure to Improve Fuel Efficiency and Reduce Emissions

Aircraft manufacturers are under constant pressure to reduce weight to improve fuel efficiency and meet environmental regulations. Additive manufacturing directly addresses this by enabling lightweight designs using titanium alloys and composites without compromising strength. Every kilogram reduced translates into fuel savings and lower emissions over an aircraft's lifetime.

Driver: Cost Reduction Through Part Consolidation

One of the most practical advantages of 3D printing is part consolidation. Multiple components can be merged into a single printed unit. This reduces assembly time, lowers inventory requirements, and minimizes maintenance issues. Fewer parts mean fewer failures and lower long-term operational costs.

Browse in Depth: https://www.meticulousresearch.com/product/aerospace-3d-printing-market-6244

Driver: Faster Prototyping and Shorter Development Cycles

Aerospace development cycles are traditionally long. Additive manufacturing shortens this timeline significantly. Design validation, testing, and modification can happen faster, enabling quicker movement from concept to production. This speed is becoming crucial in both aviation and space programs.

Restraint: Certification Still Slows Adoption

Despite the advantages, certification remains a major bottleneck. Aerospace components must pass strict testing for fatigue resistance, structural integrity, and long-term performance under extreme conditions. The certification process is expensive and time-consuming, limiting rapid large-scale adoption for critical flight parts.

Supply Chain Resilience and On-Demand Manufacturing

One of the less discussed but highly impactful benefits of aerospace 3D printing is supply chain flexibility. Spare parts can be printed locally during maintenance operations, avoiding long lead times and reducing dependency on centralized suppliers. This is particularly valuable in MRO operations and military aviation.

Opportunity: Expanding Space Programs

Space exploration is creating new demand for lightweight, high-performance parts. Additive manufacturing is well suited for rocket engines, propulsion systems, and satellite components. The potential for in-orbit manufacturing in the future adds another layer of opportunity.

Trend: Hybrid Manufacturing Becoming Standard Practice

Manufacturers are increasingly combining additive and subtractive methods. Parts are 3D printed for complexity and then finished using precision machining. This hybrid approach ensures both design flexibility and accuracy.

Challenge: Scaling for Large Structural Parts

While small and medium components are widely produced, printing large primary structures remains a technical challenge. However, improvements in printer size and speed are gradually addressing this limitation.

Regional Perspective: North America Leads

A mature aerospace ecosystem, strong R&D infrastructure, and defense investments have positioned North America as the leading market for aerospace 3D printing adoption across both commercial and military segments.

Asia-Pacific: Fastest Growing Adoption Zone

Asia-Pacific is witnessing rapid growth due to rising air travel, defense budgets, and government-backed digital manufacturing programs. Countries are investing in additive manufacturing to reduce import dependence and strengthen domestic aerospace capabilities.

Middle East: Emerging Focus on Aerospace Additive Manufacturing

The Middle East is increasingly applying 3D printing in certified aircraft cabin components and maintenance applications, improving turnaround time while maintaining aviation safety standards.

Technology Insight: Powder Bed Fusion Dominates

Powder Bed Fusion accounts for nearly half of the market due to its ability to produce aerospace-grade parts with high mechanical strength and fine surface finish. Multi-laser systems are improving production speed, making serial production more feasible.

Material Insight: Metals Hold the Majority Share

Metal materials, particularly titanium and nickel-based superalloys, dominate because aerospace applications require high strength-to-weight ratios and temperature resistance. Aluminum alloys are also gaining popularity due to cost and performance improvements. Powder recycling initiatives are further reducing material costs, improving economic feasibility.

Platform Insight: Aircraft Segment Leads, Spacecraft Growing Fastest

Aircraft applications represent the largest share due to demand from commercial and military aviation. However, spacecraft applications are growing at the fastest pace due to heavy reliance on additive manufacturing for engine and propulsion parts.

Buy the Complete Report with an Impressive Discount: https://www.meticulousresearch.com/view-pricing/1561

Outlook: Additive Manufacturing Becoming Core to Aerospace Production

Aerospace 3D printing is no longer a supplementary technology. It is becoming central to how aircraft and spacecraft are designed, built, and maintained. As certification processes mature and material capabilities expand, adoption is expected to accelerate further through 2035.

Key Questions Answered in the Report:

What is the projected market size in 2035, and what CAGR does this represent?

How much is the market expected to grow from 2025 to 2035?

Which technology leads the aerospace 3D printing market in terms of revenue share, and why?

Name some aerospace components that are being manufactured using 3D printing.

How does additive manufacturing contribute to fuel efficiency and emissions reduction in aircraft?

What role does additive manufacturing play in prototyping and product development?

What are the primary drivers for the adoption of aerospace 3D printing?

What are the main restraints or challenges facing the market?

Which region holds the largest share of the aerospace 3D printing market, and what factors contribute to its leadership?

Why is the Asia-Pacific region experiencing rapid growth in aerospace 3D printing?

Related Reports:

AI in Defense & Aerospace Market: https://www.meticulousresearch.com/product/ai-in-defense-and-aerospace-market-6379

Space-Based Synthetic Aperture Radar (SAR) Data & Services Market: https://www.meticulousresearch.com/product/global-space-based-synthetic-aperture-radar-data-and-services-market-6366

About Us:

We are a trusted research partner for leading businesses worldwide, empowering Fortune 500 organizations and emerging enterprises with actionable market intelligence tailored to drive revenue transformation and strategic growth. Our insights reveal forward-looking revenue opportunities, providing our clients with a competitive edge through a diverse suite of research solutions-syndicated reports, custom research, and direct analyst engagement.

Each year, we conduct over 300 syndicated studies and manage 60+ consulting engagements across eight key industry sectors and 20+ geographic markets. With a focus on solving the complex challenges facing global business leaders, our research enables informed decision-making that propels sustainable growth and operational excellence. We are dedicated to delivering high-impact solutions that transform business performance and fuel innovation in the competitive global marketplace.

Contact Us:

Meticulous Market Research Pvt. Ltd.

1267 Willis St, Ste 200 Redding,

California, 96001, U.S.

Email- sales@meticulousresearch.com

USA: +1-646-781-8004

Europe: +44-203-868-8738

APAC: +91 744-7780008

Visit Our Website: https://www.meticulousresearch.com/

For Latest Update Follow Us:

LinkedIn- https://www.linkedin.com/company/meticulous-research

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Aerospace 3D Printing Market Analysis 2025-2035: Trends, Drivers, Opportunities, and Regional Insights here

News-ID: 4374461 • Views: …

More Releases from Meticulous Research®

Autonomous AI and Autonomous Agents Market to Reach USD 477.8 Billion by 2035

The global autonomous AI and autonomous agents market is witnessing exceptional growth as organizations increasingly deploy intelligent automation to improve efficiency, decision-making, and real-time responsiveness across industries. Valued at USD 7.91 billion in 2024, the market is estimated to reach USD 11.5 billion in 2025 and is projected to surge to USD 477.8 billion by 2035, growing at a remarkable CAGR of 45.2% during the forecast period.

Autonomous AI systems and…

AI-Generated Fashion Market to Reach USD 75.9 Billion by 2035

The global AI-generated fashion market is experiencing explosive growth as fashion brands, designers, and digital creators increasingly adopt generative artificial intelligence (AI) to accelerate design, enhance personalization, and reduce production waste. Valued at USD 2.14 billion in 2024, the market is estimated to reach USD 2.91 billion in 2025 and is projected to surge to USD 75.9 billion by 2035, registering a robust CAGR of 38.6% during the forecast period.

AI-generated…

AI in BFSI Market to Reach USD 193.51 Billion by 2035

The global Artificial Intelligence (AI) in BFSI market was valued at USD 26.5 billion in 2024 and is expected to rise to USD 31.58 billion in 2025, growing at a rate of 19.2%. The market is projected to reach USD 193.51 billion by 2035, registering a strong compound annual growth rate (CAGR) of 19.8% during the forecast period from 2025 to 2035.

Artificial intelligence is rapidly transforming the banking, financial services,…

Global Printed Circuit Board Assembly (PCBA) Market Forecast 2025-2035: Trends, …

The global Printed Circuit Board Assembly (PCBA) market is experiencing steady growth, driven by the rising demand for advanced electronics across various sectors. Valued at around USD 86.5 billion in 2024, the market is expected to reach USD 90.91 billion in 2025 and expand further to approximately USD 147.4 billion by 2035. This represents a compound annual growth rate (CAGR) of 4.9% over the forecast period of 2025-2035. Several factors…

More Releases for Aerospace

Aerospace Wiring Harness Market will reach $4.1 billion by 2032: Amphenol Aerosp …

The Latest published market study on Global Aerospace Wiring Harness Market provides an overview of the current market dynamics in the Aerospace Wiring Harness space, as well as what our survey respondents- all outsourcing decision-makers- predict the market will look like in 2032. The study breaks the market by revenue and volume (wherever applicable) and price history to estimate the size and trend analysis and identify gaps and opportunities. Some…

Aerospace Composites Market Future Growth Insight And Competitive Outlook 2025 | …

The Global Aerospace Composites Market is expected to reach USD 57.04 billion by 2025, from USD 26.90 billion in 2017, growing at a CAGR of 9.4% during the forecast period of 2018 to 2025. The upcoming market report contains data for historic years 2015 & 2016, the base year of calculation is 2017 and the forecast period is 2018 to 2025.Global Aerospace Composites Market, By Fibre Type (Carbon, Glass, Ceramic),…

Aerospace Evacuation Market 2025 By Top Key Players UTC Aerospace Systems, Zodia …

Asia Pacific will witness a significant growth rate in the aerospace evacuation market place over the forecast timeframe. This is attributed to the increasing air travel coupled with investments in aviation industry across the region. International Air Transport Association (IATA) estimates that the region will have around 3.5 billion passengers by 2036.

Europe aircraft evacuation market holds substantial share with the expansion of airlines. In August 2018, Wizz Air announced expansion…

Aircraft Evacuation Market 2025 | UTC Aerospace Systems, GKN Aerospace, Zodiac A …

Asia Pacific aircraft evacuation market share will witness a significant growth owing to increasing demand for air travel. Further, as per IATA, the region is witnessing an annual increase of around 5.5% passenger traffic. Continuous investments by industry players for setting up of manufacturing facilities are further supporting the regional growth till 2025.

Europe aircraft evacuation market holds substantial share with the expansion of airlines. In August 2018, Wizz Air announced…

Aerospace Lavatory System Market Outlook to 2027 - Percival Aviation, Zodiac Aer …

The Aerospace Lavatory System Market research report analyzes factors affecting market from both demand and supply side and further evaluates market dynamics affecting the market during the forecast period i.e., drivers, restraints, opportunities, and future trend. The report also provides exhaustive Poter's five forces analysis.

Factors responsible to drive the growth of aerospace lavatory system is increase in the number of passengers has raised the demand for more commercial aircraft equipped…

Aerospace Control Surface Market - Spirit AeroSystems, Aernnova Aerospace, GKN A …

North America aerospace control surface market size is expected to lead owing to presence of key manufacturers in the region. Europe led by Germany, France, UK and Russia is estimated to witness significant growth in aerospace control surface market during the forecast timeframe. Advancement in technology with implementation of light weight composites allowing improved efficiency of aircraft will support the overall industry demand.

Aerospace control surface market can be segmented based…