Press release

UV Silicone Coating: Unlocking New Solutions for Efficient, Eco-Friendly Coatings to Empower Industry Upgrades

In the industries coating sector, efficiency, environmental friendliness, and precision have long been core demands. Driven by technological advancements, UV silicone coating has stood out among numerous coating processes with its unique curing advantages and broad adaptability, becoming the preferred coating solution for packaging, electronics, medical, new energy, and other industries. Today, we explore the core value, application scenarios, and key considerations for selecting premium UV silicone coating solutions.I.What is UV Silicone Coating [https://www.ndccn.com/nth1700-uv-silicone-coating-machine%ef%bc%88fully-auto-product/]? What are its core advantages?

UV silicone coating refers to a process where UV-curable coatings containing silicone components are uniformly applied to substrate surfaces via professional coating equipment, then rapidly cured under UV irradiation to form a functional silicone layer (e.g., anti-adhesive, anti-slip, temperature-resistant, weather-resistant).

Compared with traditional solvent-based or thermal-curable silicone coating processes, its core advantages are prominent:

* High-Efficiency Curing for Enhanced Productivity: UV curing eliminates prolonged solvent evaporation or high-temperature baking, completing curing in seconds. It drastically shortens production cycles, suits large-scale continuous production, and markedly increasing corporate output.

* Green & Eco-Friendly, Policy-Aligned: With high solid content and almost no organic solvents, UV silicone coatings emit no VOCs (Volatile Organic Compounds) during production. This reduces environmental impact and compliance costs, fully aligning with green production requirements under the "dual carbon" policy.

* High-Quality Coating with Stable Performance: Minimal component volatilization during curing enables precise control of coating thickness (down to micron level). The cured layer boasts strong adhesion, uniformity, and excellent resistance to high/low temperatures, aging, adhesion, and wear, meeting rigorous industry demands.

* Energy-Saving & Cost-Effective: UV curing requires significantly less energy than thermal curing processes and eliminates the need for additional solvent recovery equipment. Over the long term, this effectively reduces a company's production energy consumption and equipment investment costs.

Image: https://www.ndccn.com/uploads/NTH1700-UV-Silicone-Coating-Machine2.jpg

II. Core Application Scenarios Across IndustriesThanks to its comprehensive performance, UV silicone coating has been widely adopted in key production links across industries, serving as a critical process to enhance product quality:

1.Packaging Industry: Core Process for Release Films/PapersIn self-adhesive label and tape production, it is essential for manufacturing release films/papers. The anti-adhesive layer ensures stable peel strength and no sticking during lamination and storage, facilitating smooth subsequent processing. Its eco-friendliness also makes it suitable for food-contact packaging, improving oil resistance and anti-adhesion.

2. Electronics Industry: Protection & Adaptation for Precision ComponentsIt provides surface protection for flexible printed circuits (FPCs) to form insulating layers, preventing moisture and dust erosion. It also treats electronic films (e.g., optical, thermal conductive films) to enhance smoothness and avoid scratches during cutting and assembly.

3. Medical Industry: Dual Assurance of Compliance and Safety Meetingstrict biocompatibility, eco-friendliness, and sterilization resistance requirements, it is used for surface treatment of medical catheters, dressings, and syringe plungers. The lubricious, anti-adhesive layer improves usability and safety, while solvent-free, rapid curing supports large-scale production compliance and avoids harmful solvent residues.

4. New Energy Industry: Performance Optimization for Battery ComponentsIn lithium-ion battery production, it modifies separator surfaces to enhance heat resistance, puncture strength, and ion conductivity, improving battery safety and cycle life. It also treats photovoltaic module packaging materials to boost weather resistance and UV resistance, extending service life.

II.3 Key Considerations for Selecting UV Silicone Coating Solutions

A high-quality UV silicone coating solution directly impacts product quality and efficiency. Focus on these three aspects during selection:

1.Coating-Substrate Compatibility: Select UV silicone coatings tailored to substrate properties (e.g., PET, PP, paper, metal) to ensure adequate adhesion. Determine coating formulation based on functional requirements (e.g., peel strength, temperature resistance).

2.Precision & Stability of Coating Equipment: High uniformity demands equipment with high-precision coating heads, stable transmission, and tension control to avoid substrate deviation and uneven coating. Match UV curing system power and wavelength with the coating for complete curing.

3. Supplier's Technical Service Capabilities: Professional support is critical for process optimization. Preferred suppliers offer end-to-end services, including coating selection, equipment commissioning, and process refinement, to resolve production issues and improve yield.

Image: https://www.ndccn.com/uploads/NTH1700-UV-Silicone-Coating-Machine11.jpg [https://www.ndccn.com/nth1700-uv-silicone-coating-machine%ef%bc%88fully-auto-product/]

III.UV Silicone Coating: Empower Green & Efficient Upgrades

Amid stricter environmental policies and rising quality demands, UV silicone coating [https://www.ndccn.com/nth1700-uv-silicone-coating-machine%ef%bc%88fully-auto-product/] is becoming the top choice for industrial upgrading, thanks to its efficiency, eco-friendliness, and high performance. An optimized solution enhances competitiveness, reduces energy consumption, and enables green, sustainable development across industries.

If your enterprise is seeking coating process upgrades or customized UV silicone coating [https://www.ndccn.com/nth1700-uv-silicone-coating-machine%ef%bc%88fully-auto-product/] solutions, feel free to contact us. We provide professional technical support and equipment proposals tailored to your production scenarios, partnering to unlock new possibilities in efficient, eco-friendly coatings.

Image: https://www.ndccn.com/uploads/NTH1700-UV-Silicone-Coating-Machine1.jpg [https://www.ndccn.com/nth1700-uv-silicone-coating-machine%ef%bc%88fully-auto-product/]

Media Contact

Company Name: NDC ENGINEERING & MANUFACTURING(FUJIAN)CO.,LTD

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=uv-silicone-coating-unlocking-new-solutions-for-efficient-ecofriendly-coatings-to-empower-industry-upgrades]

Country: China

Website: https://www.ndccn.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release UV Silicone Coating: Unlocking New Solutions for Efficient, Eco-Friendly Coatings to Empower Industry Upgrades here

News-ID: 4373568 • Views: …

More Releases from ABNewswire

Top Trends in Custom Sports Hats for 2026: Sustainability, Style, and Smart Desi …

Customized Sports Hats [https://www.crayheadwear.com/sports-hats/] are no longer just accessories - they have become symbols of identity, culture and innovation. By 2026, the market will be shaped by sustainability, bold designs, technological advancements and versatility. Here are the things that brands, designers and consumers need to know.

1. Sustainable Materials Are Standard

Eco-friendly fabrics like recycled polyester and organic cotton are very popular, and their usage is on the rise in the sports…

Glimpse of 2024 Goddess Day: Pink Gift Bags, Soft Roses, and Office Sweetness

Image: https://ecdn6-nc.globalso.com/upload/p/4165/image_other/2025-12/pink-gift-bags-soft-roses-and-office-sweetness-2.jpg

Image: https://ecdn6-nc.globalso.com/upload/p/4165/image_other/2025-12/pink-gift-bags-soft-roses-and-office-sweetness.jpg

Flipping through 2024's Goddess Day snaps: blush-pink gift bags stacked neat, rose blooms peeking through cellophane. A colleague's bun tied high, fingers fumbling with satin ribbons-smile curving as she tucks a flower into the box.

Rustle of tissue paper: someone passes a bag, another pauses to sniff the rose's faint scent. Work fatigue? Melted the second those pastel packages hit the desk.

Media Contact

Company Name: FUZHOU PHOENIX HOME CO., LTD.

Email:Send…

What Is a Diesel Generator Set? Specifications and Industry Applications

A diesel generator set [https://www.jsstpower.com/diesel-generator-set/], often called a diesel genset, is a power generation system that converts diesel fuel into electrical energy. It is widely used to provide backup power, primary power, or emergency electricity in locations where grid power is unreliable, unavailable, or insufficient. Diesel generator sets are commonly found in hospitals, factories, construction sites, data centers, farms, commercial buildings, and remote or off-grid areas.

Image: https://ecdn6.globalso.com/upload/p/4472/image_other/2026-01/13-1.png

Because of their reliability,…

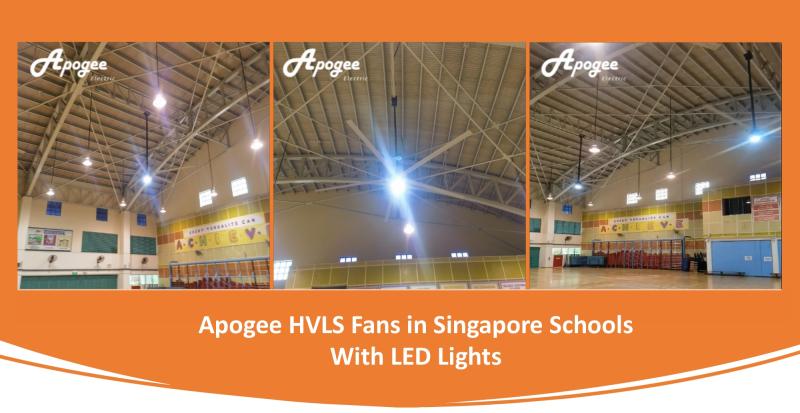

Large Commercial Ceiling HVLS Fan Industrial Cooling Fans for Singapore Basketba …

Large Commercial Ceiling HVLS Fan [https://www.apogeefans.com/dm-series-direct-drive-with-permanent-magnet-bldc-motor-product/]Industrial Cooling Fans for Singapore Basketball Court

Image: https://cdn.globalso.com/apogeefans/basketball.jpg

* 7.3m Diameter

* 14989m/min Air Flow

* 60 rpm Max. Speed

* 1200 Coverage Area

* 1.25kw/h Input Power

Commercial HVLS Fan [https://www.apogeefans.com/dm-series-direct-drive-with-permanent-magnet-bldc-motor-product/] CDM series is designed for commercial use, direct drived by IE4 PMSM Motor, very quiet 38dB and maintenance free. Suitable use for business hall, public place, schools, bars ...

PMSM Motor and drive is core technology of Apogee, we got…

More Releases for Coating

Medical Grade Coating Market: How Nanotechnology Is Advancing Coating Solutions

► Medical Grade Coating Market Poised for Significant Growth, Projected to Reach USD 22.01 Billion by 2032

The global medical grade coating market, valued at USD 13.40 billion in 2024, is anticipated to experience robust growth, reaching approximately USD 22.01 billion by 2032. This represents a compound annual growth rate (CAGR) of 6.4% during the forecast period.

Curious to peek inside? Grab your sample copy of this report now:https://www.maximizemarketresearch.com/request-sample/100541/

► Market…

Powder Coating Market - Advanced Coating Solutions for Industrial Applications | …

Powder Coating Market is expected to grow at a CAGR of 6.0% during the forecast period (2024 - 2031).

Powder Coating Market report, published by DataM Intelligence, provides in-depth insights and analysis on key market trends, growth opportunities, and emerging challenges. Committed to delivering actionable intelligence, DataM Intelligence empowers businesses to make informed decisions and stay ahead of the competition. Through a combination of qualitative and quantitative research methods, it offers…

Coating Equipment Market by Type (Powder coating equipment, Liquid coating equip …

The Coating Equipment Market research report incorporates the scope and objective of the study. Moreover, the report highlights key market segments and players covered. It also covers industry trends, focusing on market use cases and top market size by region, market trends, and global market size. Moreover, the Coating Equipment Market research report covers market growth rate and market share by region. Supply chain analysis, regional marketing analysis, opportunities, challenges,…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…